Aerobic Treatment System

In areas with deep and medium textured soil, on-site wastewater (septic) treatment systems that rely heavily on the soil for wastewater treatment such as the Conventional System are preferred (see Extension Fact Sheet PSS-2271 “Soil-based Septic System Decisions in Oklahoma” for details). However, systems that provide more advanced treatment prior to soil dispersal of wastewater are required in areas that have limitations concerning soil texture (too clayey or too sandy) and/or soil depth (too shallow to an impervious or water-saturated layer). An advanced system that has gained popularity in Oklahoma during the last decade is the aerobic treatment unit/system (ATU).

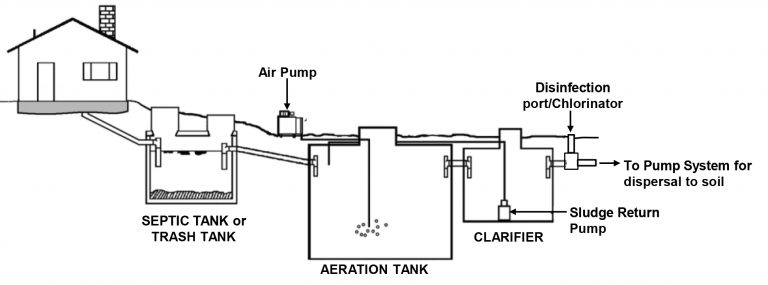

ATUs are proprietary devices that aerate the septic wastewater to enhance microbial decomposition of dissolved and solid constituents and to reduce the population of microorganisms that can cause diseases to humans (pathogenic). It is essentially a scaled-down version of a centralized activated sludge wastewater treatment plant, which attains treatment by channeling the sewage through a series of tanks designed for solid-liquid separation, aeration, static clarification and disinfection prior to effluent dispersal. Sewage purification by an ATU is accomplished by the following components (Figure 1):

- A Trash Tank where the effluent is primarily separated from the solids.

- An Aeration Tank where the wastewater is aerated (bubbled) with an air pump connected to diffusers submerged in the effluent.

- A Clarifier where undecomposed particulates and microbial masses are given time to settle in calm conditions. In most systems used in Oklahoma, the Clarifier is a chamber built into the Aeration Tank.

- A final treatment and dispersal component where wastewater is disinfected and pumped for the ultimate dispersal of the effluent to the soil either by surface spray or subsurface drip irrigation.

This bulletin focuses on the installation of ATUs, the processes taking place in each ATU component, as well as maintenance tips to keep the system in working order.

Figure 1. Schematic illustration of an aerobic treatment system treatment train (adapted from CIDWT, 2009). Note: the pump system includes a Pump Tank –not included in figure because no treatment takes place in it.

Installation and Maintenance

In Oklahoma, National Sanitation Foundation (NSF) Standard 40 aerobic treatment systems may be installed in lot sizes of at least ¾ acre if drinking water is drawn from a private well onsite. If water is from a public water system, the minimum lot size requirement is ½ acre. In addition, it can only be installed for treatment of sewage from residential units and cannot be used when the average daily flow is less than 100 gallons per day (gpd) or greater than 1,500 gpd. If the daily flow fluctuates such that daily flow occasionally exceeds the unit’s daily capacity, an ATU may still be used if a flow equalization tank is installed between the trash tank and the aeration tank.

The type of soil used for treated wastewater dispersal is another consideration. Areas with soils that do not meet minimum requirements for simpler systems (i.e., conventional system) can have an ATU provided that minimum requirements for ATUs, as summarized in Table 1, are met. Table 1 also shows that for a given soil group; vertical separation requirements (distance between the application depth and subsurface limiting layer) for ATUs are shorter than for conventional systems. This is because effluent coming out of the ATU had been pre-treated more effectively and can be finally purified by a shorter thickness of soil.

Table 1. Minimum vertical separation requirements for conventional system and aerobic treatment systems. Source: DEQ, 2012.

| Prevalent Soils Group in Vertical Separation1 Range | Conventional System Subsurface | With Aerobic Treatment Units | With Aerobic Treatment Units |

|---|---|---|---|

| Absorption Field | Drip Irrigation Field | Spray Irrigation Field | |

| 1 (coarse sand, loamy coarse sand) | NOT ALLOWED | at least 18" vertical separation | Allowed for all Soil Groups |

| 2 (sand and loamy sand excluding loamy coarse sand) | at least 24" vertical separation | at least 14" vertical separation | Allowed for all Soil Groups |

| 2a (sandy loam) | at least 21" vertical separation | at least 12" vertical separation | Allowed for all Soil Groups |

| 3 (sandy clay loam, loam, silt, silt loam with < 20% clay) | at least 18" vertical separation | at least 10" vertical separation | Allowed for all Soil Groups |

| 3a (sandy clay w/o slickensides, silt loam with > 20% clay) | at least 14" vertical separation | at least 8" vertical separation | Allowed for all Soil Groups |

| 4 (clay loam, silty clay loam) | at least 10" vertical separation | at least 6" vertical separation | Allowed for all Soil Groups |

| 5 (sandy clay with slickensides, clay, silty clay) | NOT ALLOWED | at least 6" vertical separation | Allowed for all Soil Groups |

1 Vertical Separation: The vertical distance between the bottom of a subsurface trench or the wastewater application depth and the limiting subsurface layer which could either be an impervious rock layer or a water-saturated layer.

Once installed, the top of each tank (trash tank, aeration tank, pump tank) should have no more than one inch variation in elevation from side to side and end to end. In addition, the top of all components of the aerobic treatment system, excluding the trash tank and the dispersal field should be covered with no more than 24 inches of soil (ODEQ, 2012).

The installer of any aerobic treatment system in Oklahoma is required to maintain the system for a period of two years following the date of installation at no cost to the owner. During this mandatory two-year maintenance period, the installer shall be responsible for the following:

- repairing, adjusting and replacing of any broken or malfunctioning parts;

- measuring and recording the depth of the sludge in the trash tank at least once every six months;

- measuring and recording the volume of sludge in the aeration tank at least once every six months;

- notifying the owner in writing of any repairs, adjustments and replacements, the sludge

depth measurements and the possible need for the sludge to be pumped-out.

The Trash Tank

Trash tanks permitted for installation should meet requirements of the American National Standards Institute (ANSI)/NSF Standard 40. The trash tank must have a minimum liquid capacity of 300 gallons or the average daily flow, whichever is greater.

The main function of the trash tank is to separate the effluent from the solids that settle and from the oil and grease that float. This clarifies the effluent before it flows into the succeeding tank in the treatment train. Minimal treatment of contaminants occurs in the trash tank. Ammonium (NH4+) is the main dissolved form of nitrogen, while much of the phosphorus in the sewage is locked in the settled solids. Wastewater in the trash tank is anaerobic causing anaerobic and facultative (survives both in aerobic and anaerobic conditions) microorganisms to dominate. This leads to two things:

- The rate of the decomposition process under anaerobic conditions is slow causing the solids to accumulate;

- Minimal disturbance of the activity of pathogenic bacteria (which are largely anaerobic).

Aeration Tank/Aeration Chamber

The aeration tank must meet the most current ANSI/NSF Standard 40 and accommodate the projected daily flow. It also must have an opening of sufficient size to allow for maintenance. Since atmospheric air is forced into the chamber by a compressor or aerator, a venting mechanism for proper airflow through the aeration tank is required.

The main function of the aeration tank is the removal of the organic matter and the reduction in activity of pathogenic microorganisms (microbes). Treatment in the aeration chamber is a biological process in which microbes consume the waste and transform it into non-polluting or relatively less-hazardous by-products. When atmospheric air (with about 21 percent oxygen) mixes with the wastewater, conditions become aerobic leading to a higher rate of microbial activity inside the chamber. This promotes decomposition (up to 98 percent) of the solids and dissolved organic constituents in the wastewater including antibiotics, pharmaceuticals and household chemicals.

In addition to increasing the decomposition rate, the aerobic condition in the tank also results in the following:

- Dissolved NH4+ is converted to nitrate (NO3–); no considerable change in speciation of dissolved phosphorus is expected.

- Pathogenic bacteria may be killed or weakened under aerobic conditions. In addition, aerobic bacteria will dominate and could out-compete the bacterial pathogens.

It is important to keep in mind that microorganisms in the aeration tank need to be constantly fed to maintain an active and diverse population, so they can effectively decompose a variety of materials. Microorganisms in the aeration tank will not thrive in situations with an extremely low food supply such as in a seasonal-use facility or vacation home.

Clarifier or Settling Chamber

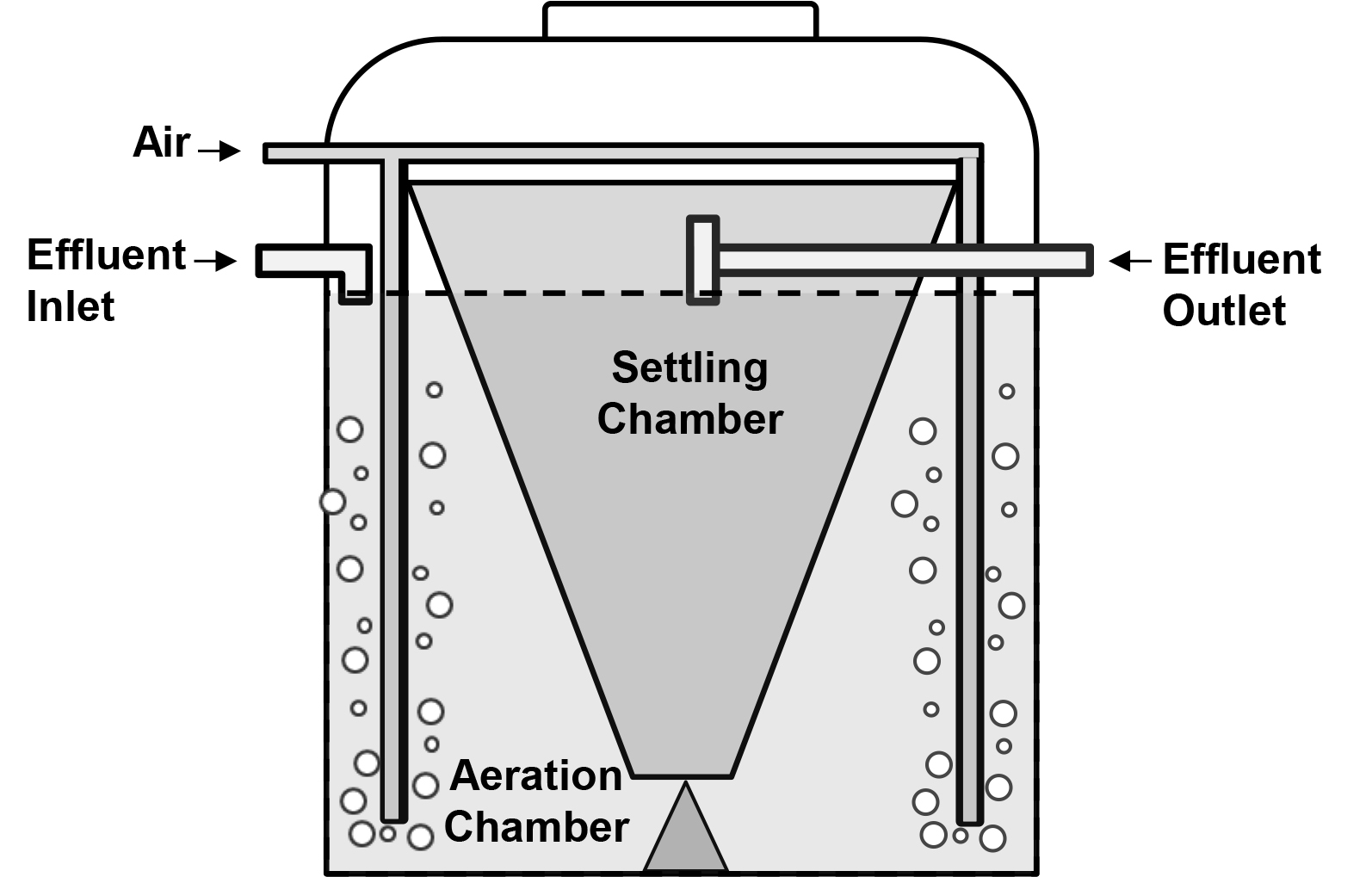

Treated wastewater exiting the aeration chamber enters the clarifier or the settling chamber. For most systems in Oklahoma, the clarifier is in the same tank as the aeration chamber (see Figure 2). The effluent entering the clarifier contains suspended solids (cell masses and non-degradable materials). The solids must be removed to prevent clogging caused by carryover of the solids to the orifices or nozzles of the dispersal lines. Calm conditions in the clarifier allow biomass suspended in the wastewater to settle. Sludge collected in the clarifier should be returned to the aeration chamber.

Figure 2. Schematic illustration of a tank with both aeration and settling chambers.

Disinfection

If spray irrigation is used as the mode of dispersal, then the effluent needs to be disinfected. If the effluent is dispersed by subsurface drip irrigation, disinfection is not required. Disinfection is performed after the effluent has gone through the clarifier, but before it is pumped for dispersal. The most common method of disinfection is by chlorination. Manufacturer instructions about chlorination must be followed. Ultraviolet irradiation is an option, but seldom used.

Dispersal

Effluent from the clarifier flows into a pump tank, where it is channeled through subsurface lines and eventually land-applied by either surface spray or subsurface drip irrigation. No biological treatment process takes place in the pump tank. The pump tank should meet ANSI/NSF Standard 40 and have a minimum liquid capacity of 700 gallons or, for systems with an average flow capacity of 350 gpd, have a liquid capacity of at least twice the average daily flow. A sampling port at the discharge outlet or in the treated effluent line following the pump tank is required for monitoring access. In Oklahoma, pump tanks are also required to have a high-water alarm set to alert the owner/operator if the tank is more than half full.

For systems with subsurface drip irrigation, the drip lines should be buried eight to ten inches deep and installed according to manufacturer specification. Emitters should be spaced one foot apart for soil groups 1, 4 and 5; and two feet apart for soil groups 2, 2a, 3 and 3a. The emitter should be set to wet 4 square feet, and be pressure compensating to deliver uniform distribution regardless of the pressure entering the drip line. The required length of the drip line will depend upon the soil group (classified according to soil texture as indicated in Table 1) and the number of bedrooms in a residence as shown in Table 2.

Table 2. Minimum drip line trench length (feet) of individual drip irrigation fields. Source: ODEQ, 2012.

Number of Bedrooms in Residence1

| Soil Group | Two or Fewer | Three | Four | Each Additional Bedroom |

|---|---|---|---|---|

| 1 | 125 | 165 | 205 | 40 |

| 2 | 160 | 210 | 260 | 50 |

| 2a | 250 | 330 | 410 | 80 |

| 3 | 340 | 450 | 550 | 100 |

| 3a | 500 | 665 | 830 | 165 |

| 4 | 660 | 880 | 110 | 220 |

| 5 | 1000 | 1330 | 1660 | 330 |

1 Based on average flow of 6,000 gallons per month for a two-bedroom residence with an additional 2,000 gallons per month for each additional bedroom. The size of the system should be increased if the actual or anticipated water usage exceeds this average.

Systems with spray irrigation require a dispersal area that is vegetated and landscaped, and/or terraced to prevent runoff. At least two spray heads are required to disperse the treated effluent. The sprinklers must provide uniform distribution of effluent over the entire spray irrigation field without misting. It must be adjusted and maintained to prevent runoff and dispersal should be controlled by a timing device that turns the pump on between 1:00 a.m. and 6:00 a.m. The required minimum area of the spray irrigation field is determined by the soil group, the number of rooms in a residence and the net evaporation zoning of the area (note: Oklahoma is divided into 10 Net Evaporation Zones). Information about area requirements for spray irrigation fields can be found at DEQ Rules and Regulations.

Maintenance

The aerobic treatment system has components requiring regular maintenance. Maintenance starts by following manufacturer’s guidelines. Take the following as suggestions to keep your system in working order:

1. Know your installer.

Know your installer and request that you be oriented to the operation and maintenance of your system. If you bought a used house, determine if the warranty can be transferred to you. Knowing the installer will at least point you to the person who is familiar with your system whom you can call for future maintenance and repairs.

2. Work within the daily treatment capacity of your system.

A family in a three-bedroom home should not exceed the treatment capacity of a system designed to treat 266 gallons of waste water per day. However, sometimes you may have visitors, causing daily water use to possibly double. During these times, a homeowner needs to make adjustments. An example adjustment would be to stagger significant use of water in the house. It would be unwise to use the bath tub, clothes washer and dishwasher at around the same time.

3. Monitor the accumulation in the trash tank and in the aeration tank.

The best way to prevent overwhelming of the trash tank is to monitor the amount of solid accumulated at least every six months. This can simply be done by dipping a long stick into the tank to measure the thickness of the accumulated solids at the vicinity of the outlet baffle. The tank should be pumped if the sludge layer has built up to within 40 percent of the liquid capacity of the tank. Follow manufacturer suggested methods of testing the sludge accumulation in the aeration tank.

4. Be familiar with your system.

Keep a record of the diagram of the tank, the location of the access ports and check wells, soil treatment area and repair area locations. It would even be better if there are markers of actual locations in the field. Knowing the location of various components makes it easier to implement measures to protect them from being disturbed/destroyed and easier to locate them for maintenance/monitoring purposes.

5. Maintain the dispersal field.

Properly maintaining the dispersal field starts with knowing the location of the buried lines and/or nozzles. To ensure proper functioning of the soil in your dispersal field, you have to do the following:

- Maintain adequate grass cover over the area. Deeply-rooted shrubs and trees should not be allowed to grow within the dispersal field.

- Divert surface waters (runoff and water from gutters) away from the tanks and dispersal field.

- Keep heavy traffic like automobiles and heavy equipment off the dispersal field.

6. Perform regular simple checks on your system.

Listen to your system. You should hear the compressor running indicating that the equipment is forcing air into the aeration tank. Check chlorine levels often making sure that adequate chlorine (bleach) should be present. Check for foul odor often. Foul odor (like rotten egg) could be an indication that the system is not working properly. Check the nozzles/spray heads regularly. Faulty spray heads is a common problem of ATUs with spray irrigation.

7. If an alarm sounds, call your maintenance provided.

Do not try to repair the system yourself. Until the problem is fixed, reduce nonessential water use in the house.

8. Be aware of what NOT to put in your drain.

There are materials, that if disposed in the drain or toilets, may limit the functioning and the lifespan of your system. Grease and used cooking oils should not be poured into the kitchen sink drain. Use of household chemicals such as bleach and other cleaning agents should be regulated. Pharmaceuticals, especially unused antibiotics, as well as pesticides, paint thinners, and solvents should never be disposed through the drain because they can adversely affect the microorganisms that help treat the sewage.

9. Allow the microbial population to recover.

Not using the system for a few weeks will lower the microbial population in the tank because of the lack of food. When you use the system again, consciously reduce the amount of household water use for at least two days. Washing a dozen loads of laundry immediately after arriving from a vacation can washout what population is left in the aeration tank.

References

Consortium of Institutes for Decentralized Wastewater Treatment (CIDWT). 2009. Installation of Wastewater Treatment Systems. 1st Ed. 454 pp.

Oklahoma Department of Environmental Quality (DEQ). 2012. Individual and Small Public On-site Sewage Treatment Systems. Title 252: Oklahoma Admin Code Chapter 641.

Lesikar, B. 2008. Aerobic Treatment Unit. Texas A & M AgriLife Extension Publication L-5302.

Sergio M. Abit Jr.

Extension Specialist for Soils under Non-agricultural Uses

John William Jones

Graduate Research Associate