Easy Access Raised Garden Bed

The Easy Access Raised Garden Bed was developed in response to requests by gardeners for a relatively low cost bed with a sufficiently high growing platform to enable gardening in the standing position. It is my hope that this design will assist senior and physically challenged gardeners to more fully engage and enjoy their gardening experience.

The use of discarded truck (tractor-trailer) tires to create an elevated base for the bed is what makes this design unique and reduces construction costs. The tire base is arranged in such a way as to permit the gardener to place one foot under the bed while standing at the side of the bed, effectively reducing stress on the lower back.

This design can be used to construct a bed of any length and up to 35 inches in height. The height can be lowered to accommodate shorter (younger) gardeners by simply reducing the length of the framing material.

The plans outlined in this publication are specific for construction of a 10-foot long by 40-inch wide by 35-inch high bed. Six tires are needed for the construction of this bed.

Instructions

- Parts List

Bed length: 10 feet - Total cost $366.60 on November 2020

- 2 - Corrugated metal roof sheeting (galvanized) 26-inch x 8-foot

- 6 - Truck tires (295/75R22.5) or (275/80R22.5)

- 16 - 2-inch x 4-inch x 8-foot pressure treated lumber

- 3, 1-lb boxes - Deck screws (3-inch)

- 1 Box (35 count) - Sharp point self tapping sheet metal roofing screw (1.5-inch)

- 1 Box (100 count) - Wood screws (no. 8 x 1-inch)

- 8 - Hanger brackets (2-inch by 4-inch lumber)

- 2, 15-oz cans - Spray-on truck bed coating

- 4 tubes - Silicon caulking (clear)

- 2 cans - Foam sealant (spray)

- 1.5 cubic yards - Fill soil (for base)

- 2 cubic yards - Growing medium (amended topsoil)*

*Cost of growing medium will vary dependent on composition (% sand, compost, bark, other amendments) and trucking expense

- Tool Requirement

- Cordless drill

- Cordless circular saw

- Impact driver

- Cordless jig saw

- Plastic long tape

- Retractable tape measure

- Carpenter's level (4-foot)

- Torpedo level

- Mason's string line

- Garden rake

- Shovel

- Sledge hammer (4 lb.)

- Carpenter's square (16-inch x 24-inch)

- Line level

- Pocket knife

- Sharpie

- Sharpie paint marker

- Carpenter's pencil

- Tin snips

- Rebar stakes (two, 1/2-inch x 48-inch)

- Tire SpecificationsAs with automobile tires, there are several different sizes of truck tires. This publication calls for the use of 295/75R22.5 or 275/80R22.5 size tires. These similar sized tires are very common and should be readily available.

- Tire Selection and Preparation

Obtain six scrap truck tires. Check local truck tire stores for availability. Many truck stops offer tire repair services and will have used tires. While the tires are free, they are also heavy so plan on taking a friend to load the tires. To reduce the possibility of injuring your back, use a ramp to roll the tires onto a trailer. One person can roll a tire while it may take two to tote the tire. Also, select only intact tires. Avoid tires that are shredded or that have exposed steel belts. On a safety note, always wear gloves when working with tires.

To simplify construction, select tires that are the same diameter. The same classification of tire can vary by as much as an inch in diameter due to tread wear. No two used tires will have the exact same diameter, so be realistic when making your selection. For best results, the tires should not vary more than ¼-inch in diameter.

The most accurate method you can use to determine tire size involves the use a tape measure to measure circumference. Tires having the same circumference are identical in diameter. Use a paint pen to note the diameter of each tire. Diameter can be calculated by dividing the circumference by 3.14.

While not absolutely necessary, the use of a circular alignment guide during construction greatly simplifies the task of aligning the tires to form a straight bed. The guide also enables accurate positioning of the bed frame members. Our circular guide is made from ¼-inch plywood and is 23-3/8 inches wide. Use a jig saw to prepare the alignment guide. Use a framing square and marker to cross mark the guide. The guide is used to designate four equidistant corners on each tire.

With the alignment guide centered on the tire, use a white paint pen and straight edge to designate four corners on all six tires.

A tape measure can also be used to accurately locate all four corners but this method requires measuring all six tires.

- Site Preparation

Prepare the site for the bed. The bed requires a level surface so it may be necessary to till the soil in order to level the site. If a perennial sod is established on the site, consider eliminating it with the use of a herbicide such as glyphosate (Roundup) prior to leveling. Designate the ends of the bed by driving two rebar stakes into the ground 10 feet apart. The stakes should extend out of the soil 24 inches. Use a torpedo level when driving the stakes to insure they are installed plumb. Attach a string line between the stakes making sure the line is taut. This line represents the central axis of the bed. With the line positioned six inches above the soil, attach a line level. Adjust one end of the line until it is level.

Next, use the line to gauge if the ground is level. Using a rake, move the soil around until the site is level 20 inches to either side of the string. In situations requiring deep tillage to level the site or when a large quantity of fill is required to form a pad for the bed, make sure to pack or roll the soil (site) prior to bed construction to prevent settling of the bed. A good rain or sprinkle irrigation on the site will also aid in settling the soil. Remove the string line following site leveling.

- Base Construction

Form the base of the bed by aligning the tires in a row between the stakes. It is much easier to move tires by rolling as opposed to dragging. If the tires you have chosen for the bed vary slightly in diameter, designate the larger ones for use on this row.

Depending on the diameter of the tires, the tires may or may not touch each other when aligned in a row. When setting the tires into place, the paint marks on adjacent tires should be directly across from one another. Reattach the string line and position just above the tires. To insure the tires are positioned in a straight row, the paint marks on the tires must be aligned with the string line.

The use of the paint mark and string technique to align the tires is especially helpful when constructing long beds because the longer the bed, the more difficult it becomes using line of site to center objects like tires that do not have straight edges.

A carpenter’s level may be used to insure the base is level side to side. A long section of square tubing or angle iron can be used to check the level of the bed end to end. If you did a good job of leveling the site, the base row of tires should be fairly level. If not, lift the tires where needed and remove or add soil until the base is level.

With the string line removed, install the top row of tires making sure the paint marks on adjacent tires are directly across from one another. Reattach the string line and position just above the top row of tires. Once again, align the paint marks on the tires with the string line. Be sure each tire in the top row is centered on the tire below it. Remove rebar stakes and string line.

With the tire base in place, fill the tires with soil. You can choose to fill the first tier of tires before adding the second or fill both tiers at the same time. Work the soil towards the outer edges of the tires to fill as much of the available space as possible. Because plants will root down into the tires, choose a loam or sandy loam as fill. There is no need to amend the soil used in this step of bed construction.

- Frame Construction

Using 2-inch by 4-inch treated lumber, prepare the vertical frame members. Three, 32-inch long frame members can be cut from one, 8-foot board. The number of frame members will vary depending on bed length. A 10-foot long bed will require 40 members.

Select six of the members for installation on the bed sides. Mark a line down the center of these six vertical frame members as shown. The lines will serve as reference points during installation.

To avoid splitting the frame members when attaching to the tire base, pre-drill pilot holes for the 3-inch deck screws. Locate a set of two pilot holes 2-½ inches from one end of the wood member and another set 13 inches from the same end. All holes should be ¾ inch from the edge of the member. Preinstall screws to make installation easier. On the six members that received a reference line be sure and install the screws on the side opposite the reference line.

Prior to installing vertical frame members, decide on the height of the bed. A bed height of 35 inches can be achieved using 32-inch long vertical members and a couple of 2-inch by 4-inch blocks to elevate the frame members. To lower the height of the bed, simply shorten the length of the frame members. To prevent rotting, never install the wood frame members with the base resting on the ground.

Before fastening the six vertical frame members to the sides of the tire base, align the reference line on the back of the vertical members with the mark on the tires. Use a torpedo level to make sure the members are plumb.

Use a 4-foot level to insure the top of each vertical frame member is level with the opposite and adjacent members.

If the top tire in a particular stack is smaller in diameter than the base tire, you may need to use a shim in order to plumb the vertical member. To avoid the need for shims, select tires with similar diameters.

Once the installation of the six vertical frame side members is completed, frame in the ends of the bed using additional vertical members. Check the level of each frame member before attaching. Cut to fit the last vertical frame member installed on each end of the bed.

Fortify the frame at each end of the bed by connecting the individual vertical members along the top of the frame. Start at one side and work your way to the other side connecting the members using 3-inch deck screws. Be sure and drill pilot holes to reduce the chance of splitting.

By design, the center vertical frame member on each side of the bed is required to handle a greater portion of the soil load in the bed. To make sure it doesn’t pull lose from the tire, insert a third, 3-inch deck screw just above the other screws.

Completed installation of vertical frame members. A total of 40 vertical members are needed when constructing a 10-foot long bed.

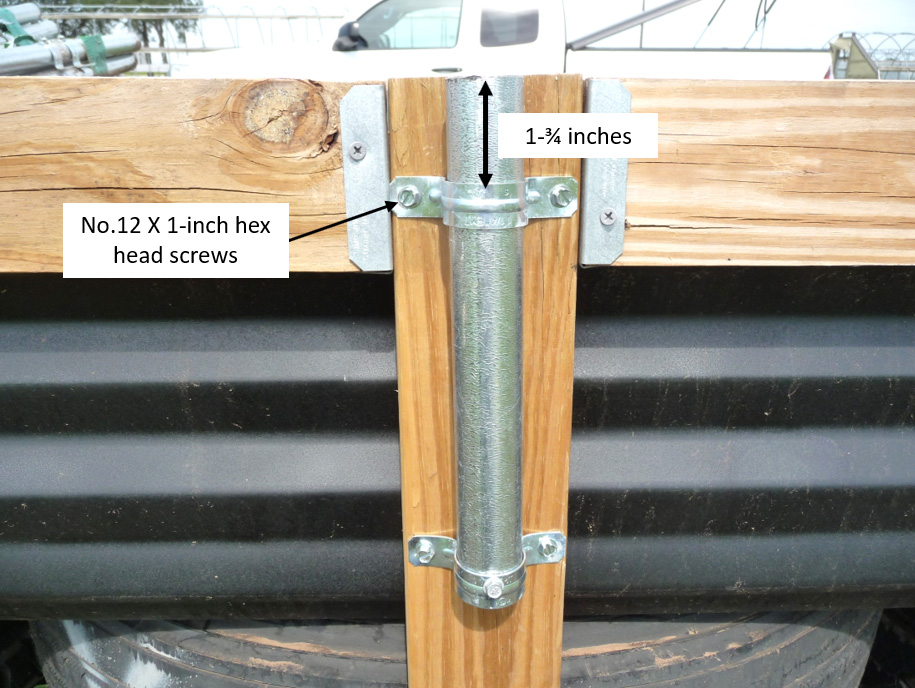

Next, attach the 2-inch by 4-inch hanger brackets to the six vertical frame side members as shown. Position the base of each bracket 3-½ inches below the top of the frame member. With the bracket correctly positioned on the side of the member, mark the locations for the screws.

Drill pilot holes prior to attaching the bracket. Use 1-inch wood screws to attach the bracket to the frame member.

Complete construction of the frame by installing the cross members. Cut each member to fit. Install using 1-inch wood screws. Remember to drill pilot holes before inserting screws. Frame construction is now complete.

- Liner Installation

Two pieces of corrugated sheeting are required to make a liner for the bed, each piece lining one half of the bed.

Begin preparation of liner by applying a spray-on truck bed coating or a rubber based coating such as “‘Flex Seal” to the corrugated metal sheeting. The galvanization imparts rust protection to the metal; however, because the corrugated sheeting is designed for use on roofs and not as a liner for garden beds, it is highly recommended you apply a coating. One coat is good; two is better.

Using tin snips, cut both pieces of sheeting to fit your bed. When constructing a 10-foot long bed, the liner should measure between 79 and 80 inches in length. Before cutting, measure the bed to make sure each piece is long enough to attach to the vertical frame side members on each end of the bed.

To assist with the installation of the liner, mark a line on the inner surface of the cross members one inch from the top.

Center a sheet on one side of the bed and align the top with the line on the cross members. Attach the top of the sheet to the frame using a minimum of five, 1-½ inch self tapping roofing screws. Repeat process on the opposite side of the bed using the other metal sheet.

Bend the sheets to conform to the shape of the bed. Holding each sheet in position, attach the free edge to the tire base using roofing screws.

Using the remaining pieces of sheeting, cut two pieces to cover the gaps in the tire base and fasten with roofing screws.

Finish the liner installation by inserting three roofing screws in the middle of each sheet along the fold

- Seal Gaps

Seal the gaps between the vertical frame members using clear silicon caulking. Seal the gaps at all four corners of the bed using foam sealant. After the foam cures, use a knife to remove excess.

Use foam sealant to seal to gap between vertical frame members and tires on each end of the bed.

- Growing Media OptionsThe bed base and the frame are strong enough to permit filling with topsoil. To insure adequate drainage, we recommend using a coarse textured soil such as fine sandy loam. Although more expensive, excellent results can be expected using a commercial potting soil or nursery mix as fill.

Easy Access Raised Bed Mini Tunnel Crop Cover - Assembly and Installation Plans

Now that you’ve constructed an Easy Access Bed, consider taking your gardening experience to a new level. A mini tunnel cover will enable you to extend the growing season and protect plants from inclement weather. The mini tunnel can be assembled in less than a day using materials available at any home improvement store. While construction grade poly film may be used as a covering for the tunnel, it will need to be replaced on an annual basis due to sunlight degradation. For extended life, choose a greenhouse grade poly film available from greenhouse (horticulture) supply stores, local or online.

- Mini Tunnel Crop Cover Parts List

Total Cost in November 2020 was $98.80.

- 20 - Pipe hanger (1-inch Rigid)

- 1 - ‘Top rail’ chain link fence tubing (1-3/8-inch x 10-foot)

- 1 Box (50 count) - Hex head screw (No. 12 x 1-inch)

- 1 Box (50 count) - Self-drilling Tek screw (No. 10 x ¾-inch)

- 5 - PVC conduit (¾- inch x 10-foot) gray

- 2 Packs (4 count) - Eye Screw (No. 10 x 1-3/8-inch)

- 1 - Braided nylon rope (3/16-inch x 50-foot)

- 1 Container (8 count) - Bail bungee

- 1 Pack (4 count) - Hook screw (1-1/4-inch)

- 2 - Bungee cord (4-foot)

- 2 - Tennis balls (used)

- 1 - Greenhouse poly film (8-foot x 18-foot x 6 mil)*

*Eight-foot and 18-foot film widths are not standard. Expect to purchase either a 10-foot or 20-foot wide section of film and cutting it to size. An 8-foot X 18-foot section of film is recommended for covering a 3-foot high mini tunnel. Custom cut sizes of greenhouse film are available from FarmTek.

- Crop Cover

Start by installing the hoop receptacles. Attach a 10-inch long hoop receptacle to the sides of the initial six side frame members as shown using 1-inch (Rigid) pipe hangers and wood screws. Fabricate hoop receptacles from 1-3/8 inch diameter ‘top rail’ chain link fence tubing. Insert a Tek screw into the bottom hanger as shown.

Install the remaining four hoop receptacles on the ends of the bed, two on each end. Using a tape measure as shown, mark the location of the remaining hoop receptacles approximately 18 inches from the adjacent corner receptacle.

Fabricate hoops from ¾-inch gray PVC conduit. You can adjust the height of the tunnel by varying hoop length. A 3-foot high tunnel requires three, 9-foot hoops and two, 7-foot hoops.

Install hoops making sure the short hoops are installed at both ends of the bed. Hoop ends should rest on the Tek screw at the base of each receptacle.

Install eight eye screws on the underside of the cross members. Locate two screws to either side of the center vertical frame member and one screw at the opposite end of each cross member.

To accommodate a 3-foot high tunnel, cut a set of four ropes, 4-feet long and a set of four ropes, 7-feet long. Attach one end of the 4-foot ropes to the eye screws on one side of the bed and one end of the 7-foot ropes to the eye screws on the other side.

Install the poly cover. To accommodate a 10-foot long bed, prepare an 8-foot by 18-foot piece of poly film. Center the cover on the bed. Many greenhouse supply companies offer custom cut sizes of greenhouse poly film. Choose construction grade poly film as your last option.

Secure the poly cover to the hoop frame by connecting the rope straps on opposite sides of the bed. Tie a loop at the end of each 7-foot rope strap. Draw the free end of the 4-foot strap through the loop and tie off using a half hitch knot. Do not pull the rope straps taut at this time.

Attach the ends of the poly cover to the bed frame. Place a tennis ball in the center of the cover at one end and roll the film around the ball several times as shown.

While holding the wrapped tennis ball, pull the film towards you and twist the film clockwise creating an ever tightening role of film.

Attach a ball bungee cord to the poly film ‘tail’ just ahead of the covered tennis ball. The tennis ball is needed to prevent the ball bungee cord from slipping off the end of the ‘tail’.

Place the ‘tail’ against the side of the bed and insert a hook screw into the wood frame adjacent to the ball bungee as shown. Use the hook screw to secure the poly cover to the frame. You may need to wrap the bungee cord around the ‘tail’ several times to remove any slack. Repeat process at the other end of the bed.

To prevent flapping of the cover in the wind, use the rope straps to apply tension. To increase the amount of tension, loosen the knot, pull down on the free end of the strap and retie the knot. The use of a half hitch allows you to quickly untie the knot, readjust the tension and retie.

To vent the mini tunnel, pull the edges of the cover upward. Depending on the height you raise the cover, you may find it necessary to loosen the ball bungees to provide the needed slack.