Water Quality Series: Rinsing and Disposing of Pesticide Containers

- Jump To:

- Advantages of Rinsing

- When to Rinse

- Choosing a Rinsing Method

- Pressure Rinse Nozzles

- How to Pressure Rinse Small Containers (Up to Five Gallons)

- How to Triple Hand Rinse a Container (Up to Five Gallons)

- Pressure Rinsing Large Containers (Larger Than Five Gallons)

- Rinsing Time for Large Containers

Both federal law (Federal Insecticide, Fungicide, and Rodenticide Act) and Oklahoma law (35:30-17-93. Handling pesticide by commercial applicators) require pesticide applicators to rinse all empty pesticide containers properly before disposal. Under federal law (Resource Conservation and Recovery Act), a pesticide container is not empty until it has been properly rinsed. Pesticide containers that have been properly rinsed can be handled and disposed of as non-hazardous solid waste. Proper rinsing of pesticide containers can be achieved through appropriate pressure rinsing or triple hand rinsing.

Advantages of Rinsing

Rinsing Saves Money

A drip-drained pesticide container may still contain as much as three percent of its contents. Rinsing the container and adding the rinse water to the spray mix allows the applicator to make sure the expensive formulation is not wasted. The amount of money saved by proper rinsing can be more than $2.50 per 2.5 gallon container for some commonly used pesticides.

Rinsing is Environmentally Sound

Properly rinsed pesticide containers minimize risk of soil, surface water, or ground water contamination. Making container rinsing a part of the mixing/loading process removes a potential source of pesticide exposure. People, animals, and wildlife are better protected. Container rinsing helps prevent environmental contamination—and preventing contamination is an important part of pesticide management.

Rinsing Avoids Legal Problems

No matter how the container is discarded, the label, federal law, and Oklahoma law require that all pesticide containers be rinsed before disposal. Moreover, the containers of some commonly used pesticides are classified as hazardous wastes if not properly rinsed. As such, they are subject to the many rules and regulations governing hazardous waste. Improper disposal of a hazardous waste can result in fines and/or criminal penalties.

When to Rinse

Container rinsing should never be postponed. Pesticide containers should be rinsed as soon as they are emptied, while they are still moist inside. The time to rinse is during mixing and loading.

Once formulation residues have had time to dry and cake on the inside of the container, they are very difficult to remove. Rinsing pesticide containers during mixing and loading solves the problem of what to do with container rinse water—the rinse water should be added to the spray tank as part of the water used as a carrier to prepare the finished spray mix.

Choosing a Rinsing Method

Newly emptied pesticide containers can be rinsed by either pressure rinsing or triple hand rinsing. Both methods work when they are done properly. These methods are compared in Table 1.

Table 1. Comparison of rinse methods for containers up to five gallons.

| Features | Pressure Rinsing | Triple Rinsing |

|---|---|---|

| Number of Steps | 8 | 17 |

| Time Spent per Container | 1-2 min. | 4-9 min. |

| Container Types Rinsed | All* | All |

| Special Equipment Needed | Rinse Nozzle | None |

*Glass containers require a fixed rinse nozzle mounted on a drain rack.

Pressure Rinse Nozzles

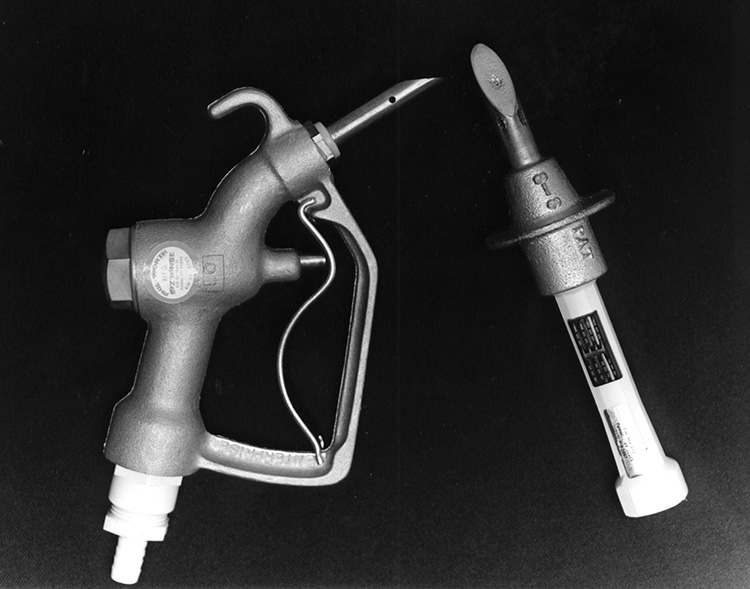

Several models of pressure rinse nozzles are manufactured. Most have similarly designed nozzle tips—a hardened, sharp pointed, steel tubular shaft with several small orifices, typically four holes drilled at 90-degree angles around the hollow shaft. The nozzle tip is joined to a valved handle with a standard garden hose fitting.

Before buying a penetrating type pressure rinse nozzle, check to see if the nozzle tip can be easily removed from the valved handle for sharpening or replacing. Nozzles that have easily removable tips are more versatile than those that have a unit-construction design. For example, if the nozzle tip is removed, the valved handle can be used to control water flow for rinsing other articles (such as protective gloves), to finish filling the sprayer tank after all containers have been pressure rinsed, or to rinse container caps.

Pressure rinse nozzles can be purchased from local pesticide distributors or from various other vendors. Heavy duty “gas pump” type nozzles will last much longer under heavy use than the lightweight plastic-body units with slide valves (Figure 1). Prices vary from vendor to vendor, ranging from $15 to $20 for the lightweight plastic units to $35 to $40 for the heavy duty metal handgrip models.

Figure 1. Rinse nozzles used for penetrating plastic or metal containers.

How to Pressure Rinse Small Containers (Up to Five Gallons)

- Wear all protective clothing and equipment required by the pesticide label. Check and adjust clothing and equipment for proper fit.

- Install the pressure rinse nozzle on a hose connected to a clean water supply capable of delivering 35 to 60 psi of water pressure. Test the hose and nozzle fittings for leaks with the nozzle turned off while the hose is under pressure.

- Remove the pesticide container cap and set it aside—place it in a location that will be easy to reach while pressure rinsing. Carefully pour the pesticide formulation into the sprayer tank. Allow the container to drip drain for at least 30 seconds.

- Hold the pesticide container upside down over the sprayer tank opening. Remove the tip guard from the pressure rinse nozzle. Firmly press the nozzle tip against the side or bottom of plastic containers and into the bottom of metal containers. Twist and push until the pressure rinse nozzle’s probe penetrates the container material and is fully seated.

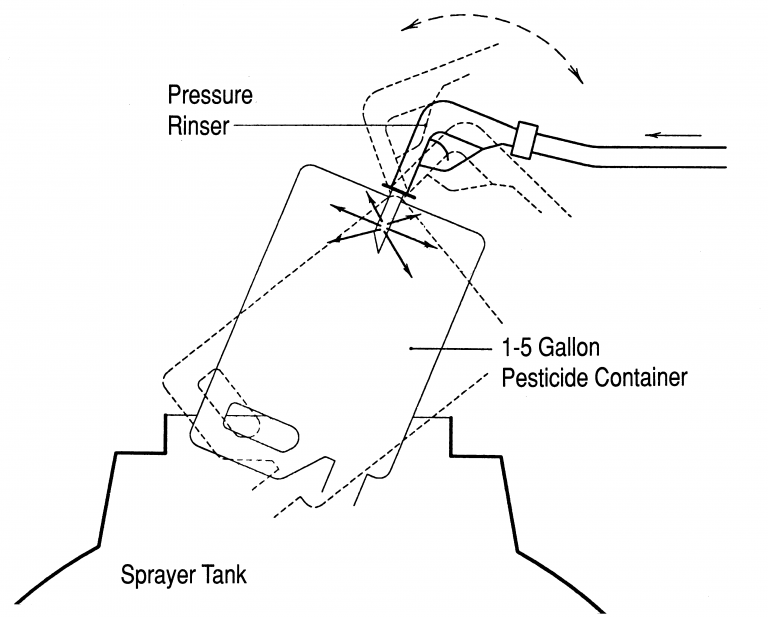

- Turn on the pressure rinse nozzle. Check to see that all rinse water drains into the sprayer tank. Rinse the container for at least 30 seconds (rinse longer if the water coming out of the container neck is not clear). To obtain complete rinse coverage on all surfaces of the container, twist the pressure rinse nozzle handle in a clockwise and counterclockwise motion and a back and forth rocking motion while rinsing. Be sure to keep the nozzle probe fully inserted during the rinsing operation (Figure 2).

- When the rinse water coming from the container is clear, retrieve the pesticide container cap and hold it in the rinse water that is pouring from the pesticide container into the spray tank. Rinse the cap in the rinse water stream until all visible traces of formulation have been washed away. Set the rinsed cap aside for separate discard.

- Turn off the pressure rinse nozzle. Remove the nozzle probe from the rinsed pesticide container and replace the tip guard. Allow the rinse water from the container to drip drain for 20 to 30 seconds. Remove the container from the spray tank fill opening.

- Dispose of the rinsed container and cap according to label instructions.

Figure 2. The pressure rinse nozzle should be fully inserted into the side or bottom of the container.

How to Triple Hand Rinse a Container (Up to Five Gallons)

- Wear all protective clothing and equipment required by the pesticide label. Check and adjust clothing and equipment for proper fit.

- Remove the cap and set it aside. Carefully pour the pesticide formulation into the sprayer tank. Allow the container to drip-drain for at least 30 seconds.

- Partially fill the container with clean water (approximately 20 percent full – 1.5 pints per gallon).

- Put the cap back on the container and tighten.

- Shake the water in the container vigorously for at least one full minute, making sure the rinse water contacts all inside surfaces several times.

- Remove the cap and carefully pour the rinse water into the sprayer tank. Allow the container to drip-drain for at least 30 seconds.

- Repeat steps 3 through 6 two more times.

- To clean the cap for disposal, place it in a container filled with heavy-duty detergent and hot water.

- Dispose of the rinsed container and cap according to label directions. Properly rinsed containers and container caps may be handled and disposed of as non-hazardous solid waste. However, local (state, county, or city) ordinances may apply. Contact local landfill authorities for specific details about disposal.

Pressure Rinsing Large Containers (Larger Than Five Gallons)

Pump and Drain

Before pressure rinsing a large container, be certain that as much formulation as possible has been pumped into the sprayer tank and the container has been allowed to drip-drain (if a drain rack is available for inverted draining) for at least one or two minutes before rinsing. If inverted draining is not an option, tip the container so the probe can suck material from the low point at the bottom/wall junction to get the most formulation out before rinsing.

Pressure Rinsing Options

Pressure rinsing a large container is similar to pressure rinsing a small container. The following are recommended methods for pressure rinsing large containers:

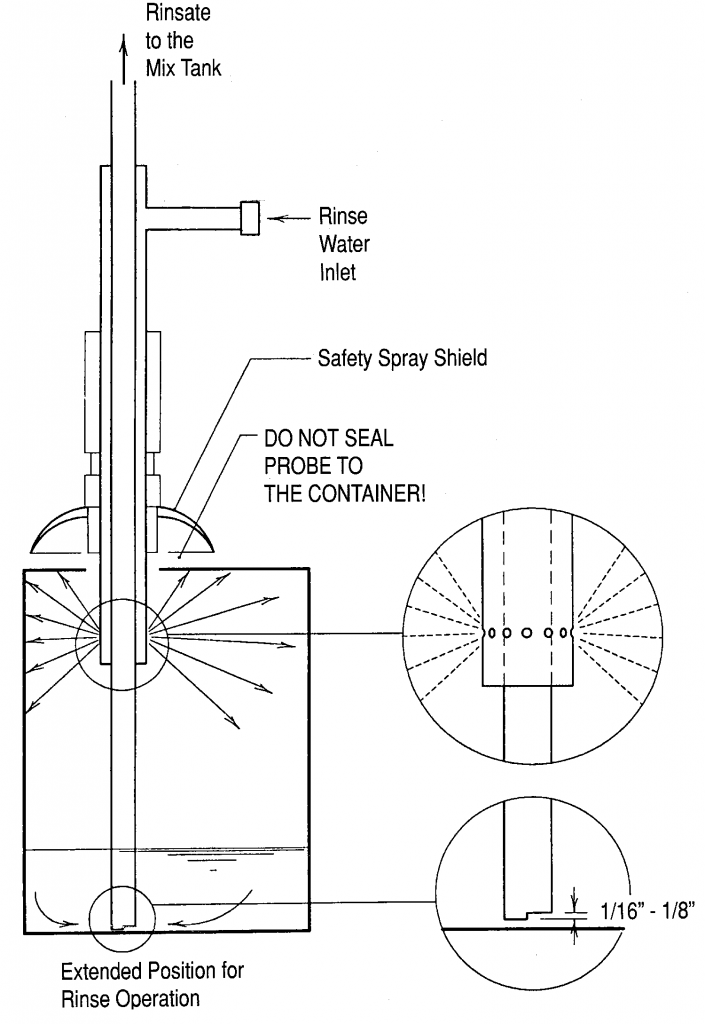

- Drain the container with a suction probe, and then place the container on an inclined

drain unit with a built-in pressure rinse probe and transfer hose connections. A special

inclined pressure rinse drain rack for 2 1/2- to 55-gallon containers has been designed

and manufactured by Tri-State Aviation (see list of distributors). This stainless

steel drain/rinse unit positions the container so it lays at about a 30-degree angle

for good drainage (Figure 3). Large empty containers can be laid easily on the inclined

triangular frame with the container opening sliding over the inclined rinse probe.

Rinsate flows out the opening around the rinse probe pipe. A suction hose connection

at the low point of the drain rack allows the rinsate to be transferred to sprayer

or rinsate holding tank during or after rinsing.

Figure 3. Inclined stainless steel pressure rinse/drain rack. - Drain the container and rinse it with a suction/rinse probe with the large container

sitting upright. Special suction probes with built-in pressure rinse orifices are

designed to rinse large containers and transfer the rinsate directly to sprayer tanks

or to rinsate holding tanks (Figure 4). These units are designed for rinsing the container

sitting on the floor in an upright or tipped/inclined position. This reduces the risk

of injury from spilling pesticide while trying to lift large containers for hand dumping

into sprayers. It also eliminates the risk of dropping heavy containers and damaging

sprayer equipment, such as aircraft wings or fuselage, or injuring personnel.

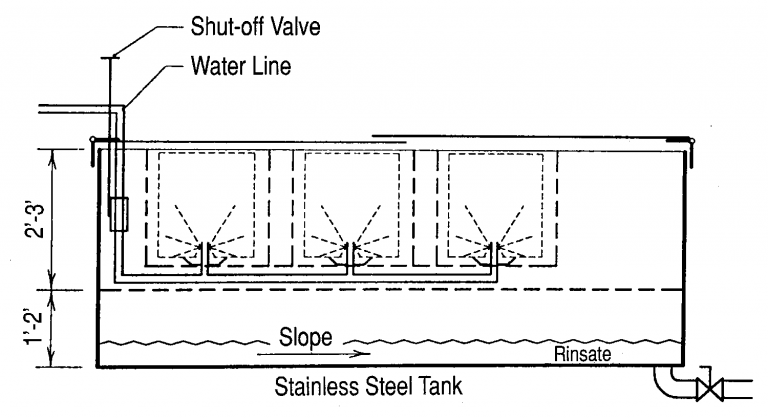

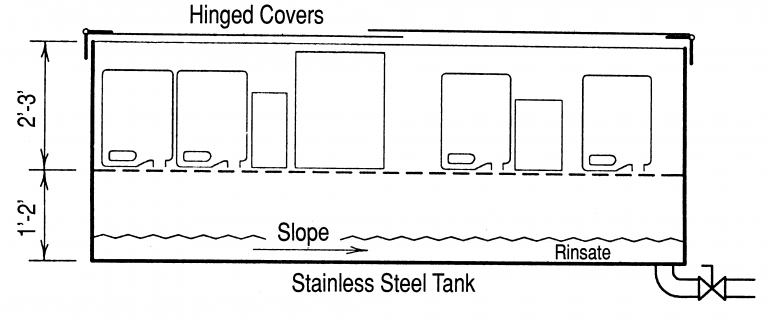

Figure 4. Suction rinse probe. - Drain the container with a suction probe and invert container over a drain rack with

built-in pressure rinse nozzles on the rinsate catch tank or batch mixing tank. Special

drain racks and rinsate drain containers are designed for setting container outlets

or pour spouts over built-in vertical pressure rinse nozzles to drain and rinse large

containers (Figure 5).

Figure 5. Pesticide rinsate drain tank with pressure rinsing.

- Drain the container with a suction probe. Drill or punch a one-half inch diameter

hole in the bottom of container inverted over a drain rack on a rinsate catch tank

or batch mixing tank. Then, insert pressure rinse nozzle (Figures 1 and 2) through

the hole and use a rotating or twisting and a rocking motion of the nozzle to spray

all inside surfaces of the container. The larger the container, the longer the pressure

rinsing operation should be. Special mix tank drain racks and rinsate collection containers

are designed for placing inverted containers over a grate for drainage and rinsing

(Figure 6). Rinsate collects in the mix tank or rinsate drain unit for transfer to

a sprayer tank or rinsate holding tank. These units are usually between waist and

chest height, so a properly clothed worker can handle all empty bulk containers except

55-gallon barrels. Special handling equipment or two people may be needed to handle

55-gallon barrels or drums safely, especially if they contain some rinsate.

Figure 6. Pesticide rinsate drain rack and tank.

Rinsing Time for Large Containers

Larger containers require longer rinsing times than smaller containers. At three to five gallons per minute of water flow from spray nozzles or probes, 30 seconds may be adequate for a small container. Thus, a 55-gallon container should be rinsed for three to five minutes (15 to 25 gallons of rinse water) compared to 30 to 60 seconds for a 2 1/2- or 5-gallon container (1 1/2 to 3 gallons of rinse water), unless high volume nozzles (10-20 gpm) are used.

Kevin Shelton

Extension Pesticide Coordinator

Charles Luper

Extension Associate