Waste Management for Alligator Farming and Ranching

The American alligator, called hvlpvta in the Mvskoke (Creek-Seminole) language, has been prized for its meat and hides for centuries. In recent decades, leather and meat from alligators is primarily derived through intensive cultivation of alligators in enclosed systems. Alligator farming and ranching are water intensive enterprises, with irrigation of wastewater the primary method of nutrient recycling. Soil adsorption of phosphorus and hydraulic infiltration rate are the primary limitations on land application of alligator wastewater.

Intensive Farming of Alligators

Raising alligators in captivity for profit increased in the 1980s due to promotion and regulation in the state of Louisiana. Ninety-eight percent of American alligator production takes place in Florida and Louisiana, with Georgia, Alabama, Mississippi and Texas balancing out the remainder of farms and ranches. Raising alligators on farms or ranches is prohibited in the state of Oklahoma.

Products from Alligators

Leather: The main product of intensive alligator production is hides to be turned into high value leather products. To be profitable, an alligator must reach 3 to 4 feet in length and weigh between 14 and 22 pounds. With intensive production alligators can reach this size in 12 to 18 months, depending on water temperature.

Meat: The second most valuable product from alligator farming is meat. Most of the meat sold comes from the alligator tail. The tail takes up half of the body of an alligator.

Novelty Items: A third source of profit from intensive alliga-tor production is the sale of novelty items: whole stuffed alligators, heads, teeth and feet.

Tourism: Prior to the 1980s, the main attraction of captive alligators was tourism, with the bulk of leather products coming from hunted alligators. Although tourism is less important to modern alligator production, farms and ranches do profit from agritourism. People seem to have an undying fascination with alligators.

Figure 1. American alligator (Alligator mississippiensis)

Cultural Practices

There are two main types of alligator facilities: alligator farms and alligator ranches.

Alligator farm: Practiced mostly in Florida, alligator farms retain breeding stock on the farm and owners collect eggs for incubation from a confined herd of females.

Alligator ranch: Practiced mostly in Louisiana, alligator ranches collect wild alligator eggs from landowners, who are, in turn, licensed by state agencies to gather alligator eggs. Ten to fifteen percent of ranch-raised alligators are then returned to the marsh to maintain wild populations.

The Nature of Alligator Manure

Digestive Anatomy

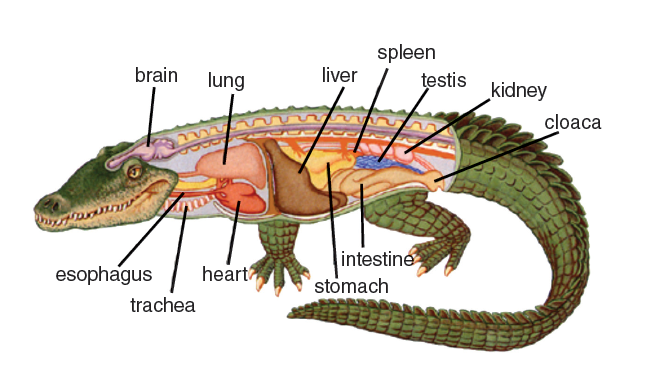

The digestive system of an alligator is shown in Figure 2. Alligators share two anatomical features in common with birds. First, their stomachs have two compartments: a gizzard and a true stomach. Similar to poultry, an alligator gizzard contains gastroliths – stones swallowed to help grind food. Alligators also use these swallowed stones as ballast for swimming and diving. Alligators in the wild swallow their prey whole. The true stomach of alligators and crocodiles is the most acidic of all invertebrates, allowing them to digest bones, feathers, hair and scales.

Figure 2. Digestive system of an alligator (from aschoen.smallgator.blogspot.com).

Second, like birds, alligators do not release urine separately from feces. Feces, which comes from the intestine and urine, which is filtered from the blood stream by the kidneys, are commingled in the cloaca. The commingled urine and feces are excreted as one mass. Also, like birds, alligators deposit a portion of digested nitrogen in the form of uric acid. In commercial production, alligator wastes are generally mixed with water. In nature, alligators deposit their excrement on land, and it appears as a mass of green or brown feces with a spot of white uric acid – very much like a bird’s excrement.

Diet

In nature, alligators are apex predators, and feed by lurking — waiting for any living creature in or near the water and those that are small enough to overpower. As such, their diet is high in protein, and their excrement contains higher amounts of nitrogen than most confined livestock. In confinement, alligators are fed prepared diets. The diet of small (less than 2 feet in length) alligators is 50% protein; whereas, larger alligators eat diets containing around 40% protein. Alligators are usually fed every other day. If fed too frequently, they are susceptible to developing gout.

Table 1 gives the expected values for total suspended solids (TSS), volatile suspended solids (VSS), five-day bio-chemical oxygen demand (BOD5), and fertilizer elements excreted by farm- and ranch-raised alligators.

Table 1. Production of solids, organic matter and nutrients from farm-raised alligators (De Los Reyes, et al., 1998).

| lb. of constituent per1,000 lb. liveweight per day | |

|---|---|

| Total Suspended Solids (TSS) | 2.0 |

| Volatile Suspended Solids (VSS) | 1.7 |

| BOD5 | 1.0 |

| Total Nitrogen | 6.3 |

| Total P2O5 | 1. 6 |

Typical Waste Management System for an Alligator Ranch

Housing

Modern alligator production takes place in well insulated houses similar to the ones shown in Figure 3. Each house is divided into water-filled pens (Figure 4). Alligators are segregated by size to reduce fighting. Each pen houses alligators of near identical length. Table 2 provides pen surface area and water depth requirements. Pens are flushed, washed and refilled with well or surface water daily or up to once every three days. Given the range of alligator sizes on a given farm, and a flushing rate of once every other day, average wash water use is approximately 10 gallons per animal per day.

Figure 4. Interior of alligator house, showing pen and feeding ramp.

Temperature of water is very important for alligator health. Pen water must be heated to between 80 F to 90 F. Given adequate nutrition, alligators will grow to 4 feet in length in 12 months with a water temperature of 88 F to 90 F. It takes 16 to 18 months to grow a 4-foot alligator housed in 80 F to 82 F water. The slower growing animals have a more desirable hide.

Figure 3. Alligator houses on a Louisiana alligator ranch

Table 2. Space and water depth requirements for alligators in confinement (Shirley and Elsey, 2015)

| Length of Alligator | Space Requirement (ft2 per Animal) | Pen Water Depth (in) |

|---|---|---|

| Less than 2 feet | 1 | 14 to 18 |

| 2 to 4 feet | 3 | 14 to 18 |

| For each 6 inches beyond 4 feet | Add 1 foot2 | 14 to 18 |

Wastewater Storage

The goal of waste handling in most alligator ranches is to recycle wastewater nutrients to grass or hay crops through land application. Crops cannot be irrigated every day because of wet soils, cropping stage and field use; therefore, a storage pond such as the one shown in Figure 5 is needed. Alligators are grown in areas where annual rainfall exceeds evaporation, so extra storage volume must be allowed for accumulating rainfall, plus stormwater storage for a 25-year, 24-hour storm.

Figure 5. Alligator wastewater storage pond.

Ranchers may opt to treat wastewater in anaerobic la-goons and store effluent for periods up to a year. Bear in mind, however, due to high protein diets, alligator wastewater has a high potential for odor, so lagoon treatment volume should be doubled from normal loading rates to control odors. Use the volatile solids excretion rates in Table 1 and information provided in OSU fact sheet BAE-1736, Lagoons for Livestock Waste Treatment to size lagoons. Table 3 provides typical pollutant strength and fertilizer concentration for alligator ranch wash water and lagoon effluent.

As a point of reference, swine lagoon effluent in areas where rainfall exceeds evaporation runs about 4-1-4 pounds N-P2O5-K20 per 1,000 gallons. Alligator ranch lagoon effluent is more dilute than swine lagoon effluent due to the high amount of flush water used in alligator production. Also, alligator lagoon effluent is higher in nitrogen relative to phosphorus than most livestock waste lagoon effluents.

Table 3. Measured organic matter and fertilizer concentrations in alligator wastewaters (Pardue et al., 1994, De Los Reyes, et al., 1998).

| Removed from Pens | First Stage Lagoon Supernatant | Second Stage Lagoon Supernatant | |

|---|---|---|---|

| TSS (mg L-1) | 380 | 380 | 760 |

| VSS (mg L-1) | 220 | 190 | 140 |

| BOD5 (mg L-1) | 450 | 110 | 67 |

| Total N (lbs. N 1000 gal-1) | 1.3 | 0.75 | 1.1 |

| NH3-N (lbs. N 1000 gal-1) | 0.65 | 0.65 | 0.64 |

| P (lbs. P205 1000 gal-1) | 0.055 | 0.050 | 0.050 |

Wastewater Irrigation

A typical irrigation spray field for alligator ranch wastewater is shown in Figure 6. As with all nutrient management plans, land required for irrigation should be determined through periodic wastewater and soil testing. That should be adjusted to meet crop nutrient needs at the right rate, time and placement (the right source being alligator wastewater). As seen in Table 3, concentration of nitrogen relative to phosphorus is higher for alligator ranch wastewater than for most manure and lagoon effluents. Even at these high concentrations, land requirements will generally be determined by phosphorus, especially if soil test phosphorus index is in the excessive range.

Another factor to consider with alligator wastewater irrigation is the system water balance. Since alligator ranches are located in humid climates, land application area may be limited by soil hydraulic intake and the available drying time between applications. Also, land application sites should pro-vide adequate buffer areas adjacent to ponds, lakes, streams, wells and sinkholes to prevent water quality degradation.

Figure 6. Field used for alligator ranch wastewater irrigation in Louisiana.

Example: Land needs calculation for alligator ranch wastewater irrigation.

Given: An alligator ranch has pen space to house 1,500 alligators ranging from hatchlings to 4 feet in length. Average weight of alligators is 11 pounds. Wastewater is stored in a lined pond, which is completely emptied several times a year through spray irrigation.

Find: Land required to properly reuse nutrients on a turf crop with an annual nitrogen requirement of 200 pounds of nitrogen per acre per year, and an allowable phosphorus application rate of 100 pounds of P2O5 per acre per year.

Solution: One thousand five hundred alligators at 11 pounds each give total average liveweight for the farm of 16,500 pounds.

From Table 1, expected nutrient production is 110 pounds of nitrogen and 26 pounds of P2O5 per day, or 40,000 pounds of nitrogen and 9,600 pounds of P2O5 per year.

Assuming a 65% loss of nitrogen during storage and application, and a 200 pounds of nitrogen per acre per year uptake rate, land required to spread based on nitrogen is 70 acres.

Assuming no loss of phosphorus in storage and application, and a 100 pounds of P2O5 per acre per year application rate, land required to spread based on phosphorus is 96 acres.

The ranch needs around 100 acres to irrigate this waste-water, based on phosphorus as a limiting factor. This land requirement may change depending on results of periodic soil and effluent testing.

Summary

Alligator farming and ranching can be a profitable agricultural enterprise. Alligator farmers and ranches must be mindful of the environmental impact of their production systems, because of high pollutant strength, high plant nutrient concentration and high odor potential of alligator wastewater. The most common waste treatment system on alligator ranches provides for nutrient recycling to crops through sprinkler irrigation. Wastewater phosphorus content, moisture-holding capacity of soil and soil hydraulic infiltration rate are the most limiting factors for alligator wastewater irrigation.

References

De Los Reyes, A.A., K.A. Rusch, and R.F. Malone. 1998. Generation and management of wastewater in an alligator farm. Journal of Applied Aquaculture 8(2): 27-38.

Hamilton D.W. and C.A.Woods. 2010. Alligator Ranch Waste Management. Video. Oklahoma Cooperative Extension and Louisiana State University Ag Center. YouTube/OSUWasteManagement.

Pardue, J.H., R.D. DeLaune, W.H. Patrick, and J.A. Nyman. 1994. Treatment of alligator farm wastewater using land application. Aquacultural Engineering 13:129-145.

Sheffield, R.E., M.J. Shirley, and W.H. Branch. 2008. Louisiana Irrigation: Alligator Washwater Management, LSU Ag Center Pub 3603. Baton Rouge, LA: Louisiana State University Agricultural Center.

Shirley, M.J. and R.M. Elsey. 2015. American Alligator Production: An Introduction. SRAC Publication No 230. Stoneville, MS: Southern Regional Aquaculture Center.

Douglas W. Hamilton

Waste Management Specialist