Understanding the Results of Master Irrigator Center Pivot Energy Efficiency Test

Background

The Master Irrigator program offered through Oklahoma State University and the Oklahoma Water Resources Board offers free energy and water delivery audits to irrigators in the state. The audit offer is usually associated with the producer attending a Master Irrigator certification class. The energy efficiency audits are performed in the feld at the producer’s center pivot system he/she is curious about. Both electric and internal combustion fueled engine pumping systems are tested. The producer is provided with a report that gives information such as: current system pumping efficiency, suggested efficiency, and potential energy and cost savings. The key metric used to evaluate the system is how well does the overall pump efficiency (OPE) compare to an established standard named Nebraska Pumping Plant Performance Criteria or NPPPC. This fact sheet discusses how the irrigation system OPE is determined, its comparison with the NPPPC standard, and what the producer can do with this information.

The Irrigation System Energy Efficiency Test

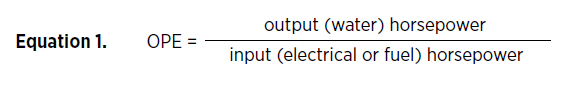

The primary goal of the irrigation system efficiency test is to compare the energy input to the pumping plant (electricity or fuel) to the water horsepower output of the pump. This measurement is known as the Overall Pumping (plant) efficiency (OPE). The OPE of an irrigation pumping system gives us an indicator of how efficiently the system is using purchased energy to produce water (USDA, 1997). The OPE also gives us clues as to how we might improve the irrigation system to be more cost effective. To determine the power/energy coming into the power plant (motor or engine), we measure either the electrical power in kilowatts (kW) via special electrical power meters or the fuel input in British Thermal Units (Btu) with fuel flow meters. These inputs are converted to horsepower readings. At the same time the water horsepower (output) from the pump is determined (see below). The output water energy is divided by the input electric or fuel input (equation 1). This is the overall pumping efficiency OPE.

Output Water Horsepower

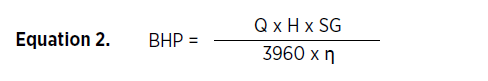

Water flowing under pressure can be described in horsepower units. The well-known equation (English Units) for this is shown below (equation 2).

Q = Flow of water; unit: gallons per minute (GPM)

H = “Head” pressure equaling to sum of water lift from depth, pressure provided, and system resistance; unit: feet (ft)

SG = Specific gravity of water, constant value of 1.0

η = System efficiency; dimensionless, percentage = %

3960 = Conversion factor for head and fow, constant

BHP = (Brake) horsepower

Head is a measure of the pressure produced as well as the resistance of the water to being pumped through the system and the units are “feet”. For groundwater irrigation systems, most of the pressure head consists of the lift to pull the water up out of the ground (in feet) and the pressure provided to move the water to the spray nozzles. The remaining pressure components of the head (pressure) measurement are restrictions in the piping, bends, valves, etc.

How Do We Measure These Inputs?

Flow (Q): We use an ultrasonic fow meter placed on the water delivery pipe exiting the pump. This device uses transducers and receivers to determine the fow rate of the water in the pipe given the dimensions and materials used to make the pipe. This meter is non-intrusive and simply clamps on and of the pipe in question.

Head (Pressure in Feet): We determine the lift by measuring the depth of the ground water to the base of the pump using various depth to water meters (Tape and sonic). We then note the dimensions of the piping and its general condition. This is entered in a spreadsheet which estimates the total head pressure.

Specific Gravity (SG): This term is unneeded when dealing with water as it is simply a ratio of the fluid in question compared to water. So, in irrigation this term is 1.0.

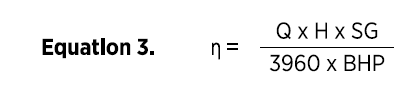

System efficiency (η): This term describes the general efficiency of the pumping system. In most cases, this term is what we are calculating as we know the brake horsepower (BHP) input from the electricity or fuel input (equation 3).

Brake Horsepower (BHP): This term is known from the power meter reading during operation for electric motors or the fuel input times the estimated engine efficiency for internal combustion engines.

Once We Measure the System’s Efficiency, What Do We Compare it to?

Using equation 1, we now have an overall pump efficiency (OPE) for the irrigation system being tested. Is the resulting number good, bad, reasonable, or other? Fortunately, there has been quite a bit of research done on pump OPE numbers over the years. The most widely used studies were conducted by the University of Nebraska (Kranz, 2010). These studies build on years of examining pumping systems and their power requirements and efficiencies. These studies are collectively known as the Nebraska Pumping Plant Performance Criteria or NPPPC. The NPPPC studies include extensive tests on internal combustion engines (Nebraska Tractor Tests) using a variety of fuels as well as electric motors.

The NPPPC OPE numbers are based on the assumptions that the pump efficiency is 75% and that the efficiency of the electric motors is 88%. These are baseline assumptions and are reasonable for systems that have been installed correctly and are working well. It should be noted that the NPPPC are not describing super-efficient systems. Rather, the NPPPC describes a well-running, average system. This is an important distinction. For example, if a system tests 80% of NPPPC. This is saying that the system is 20% below the efficiency of a reasonable system. In other words, there is considerable room for improvement. We often test systems that are above the NPPPC standard. This simply means these systems are very efficient.

Below is a table (Table 1), showing the NPPPC standards that we use in our tests. The far-right column (overall efficiency %) is the NPPPC OPE we use for comparison to the irrigation system OPE we measure in the audit.

| Energy Type | Unit of Energy | wHp-h per unit of energy | Performance rating (%) | Overall efficiency |

|---|---|---|---|---|

| Diesel | gal | 12.5 | 100 | 23 |

| Propane | gal | 6.89 | 100 | 18 |

| Natural Gas | mcf | 61.7 | 100 | 17 |

| Electric | kWh | 0.885 | 100 | 662 |

| Gasoline | gal | 8.66 | 100 | 17 |

1Efficiency given for electricity is wire to water efficiency, which is calculated at the pump site. Liquid or gas fuel is based on average Btu values.

2Overall efficiencies vary from 55% for 5 horsepower to 67% for 100 horsepower.

What Causes Systems to Test Below NPPPC?

The following are cited by the University of Nebraska as potential causes of lower OPE (Krantz, 2010).

- The pipeline is throttled-back at the well to meet pressure requirements

- Well screen is plugged due to mineral incrustation and/or iron bacteria resulting in extra pumping lift

- Worn pump impeller due to wear from pumping sand or extended use

- Improper impeller adjustment on deep well turbine pumps

- Alteration of the irrigation application system without redesigning the pumping plant

- Mismatched system components such power unit too large

- The power source may not be operating at the specified speed (rpm) for maximum efficiency

- The engine may need a tune-up

- Improperly sized discharge column

Economic Implications of Not Meeting NPPPC Standards

The Master Irrigator energy efficiency test results report delivered to the producer for their system includes an economic analysis of the possible energy and energy cost savings by improving to the NPPPC standards. We base the report on the expected energy (electricity or fuel) savings to meet NPPPC, the local average cost of energy, the rate schedules the producer is on, and the expected number of hours per year the irrigation system will be running. In some cases, the expected saving can be in the thousands of dollars per year. In other cases, the producer’s irrigation systems are performing better than NPPPC. While the latter case means no predicted savings, the information is still valuable. What is the difference between the well-performing system versus others? The information from this system can be used to benchmark other systems.

What the Master Irrigator Energy Efficient Tests Cannot Tell us About the Producer’s Systems

Currently, it is often difficult for us to determine exactly why the system OPE is low unless it is something obvious. A low OPE could be due to malfunctioning power plant (motor or engine) or it could be that the pump system is malfunctioning, or both need service. With the electric motors we have a better indicator of how the motor is performing which may point to the pump system as the efficiency problem. It is simply easier to tell how an electric motor is performing by measuring the volts, amps and power factor at the motor.

The internal combustion engines are a different story. We would need to install a dynamometer on the engine output shaft to determine the input power to the pump. Until recently, this has been a long and difficult process that involved pulling the existing driveshaft and installing a special shaft with a torque converter. We prefer not to interfere with the mechanisms as much as possible.

Why all this talk of the engine/motor versus the pump? If the problem is with the motor or engine, both are above ground and easier to repair and replace. If the problem in the pump down-hole, pulling the pump can be very expensive. Therefore, with engine systems showing a low OPE, we recommend the producer examine the engine tune first and then contact a pump service company if the engine appears to be in good shape.

References

USDA, NRCS, National Engineering Handbook – Irrigation Guide, September 1997.

Kranz, William, Updating the Nebraska Pumping Plant Performance Criteria, Proceedings of the 22nd Annual Central Plains Irrigation Conference, Kearny, NE., February 23-24, 2010.