True Cost of Energy Comparisons – Apples to Apples

Introduction

Costs for different types of energy (electric, natural gas, liquid fuel, solid-biomass) used in residential and commercial applications can be difficult to compare until they are all related to some common type of measurement. This Fact Sheet discusses the basics of “common point of use” energy cost analysis and comparison using dollars per MMBtu. A simple on-line calculator is referenced that allows users to compare different energy sources, costs and equipment efficiencies to make cost decisions.

Natural Gas vs. Electricity

The simple question: Is natural gas cheaper to heat a house when compared to electricity? – Is difficult to answer simply. These are different types of energy with different cost schemes. However, a feeling for the relative costs of energy sources can be seen if electricity and fuels are put in a common energy unit and make some assumptions about the equipment where energy is used. These provide a more common ground to compare and discuss energy sources.

Energy Units

There is an old adage in engineering that goes: You can’t examine what you can’t measure. This is especially true of energy. For residential and commercial use, energy comes in many forms such as natural gas, electricity, coal, biomass, gasoline, etc. If all the different energy forms are put into the same end-use units, comparisons could be made of energy quantities and prices (“apples to apples”). In the U.S., the main energy end-use units are British Thermal Units (Btu’s) or Kilowatt-Hours (kWh). Btu’s can also be converted to kWh and vice-versa. Btu’s are typically used to describe natural gas and kWh is used for electricity.

A Btu is about the amount of heat energy that a paper match would give off if burned. This is a fairly small quantity. For energy units of any usefulness, millions of Btu’s or MMBtu are used (the Roman numeral “M” stands for the number 1,000 and MM in “MMBtu” means 1,000 x 1,000 = 1,000,000). Another common Btu unit is the “Therm,” which equals 100,000 Btu’s, or one-tenth of an MMBtu. A Dekat-herm is equal to 10 Therms and an MMBtu. Natural gas is usually bought and sold in MMBtu’s or Therm’s. Sometimes natural gas is described as 1,000 cubic feet (MCF) which is approximately 1 MMBtu.

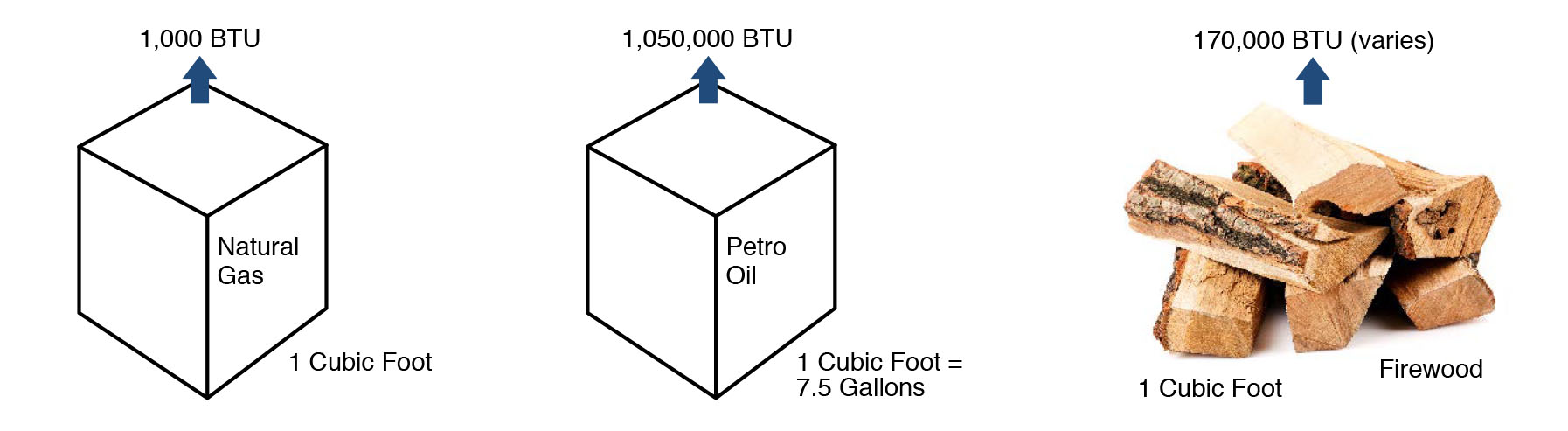

Fuels are often sold in different units. Additionally, fuels have different amounts of energy for the same volume (See Figure 1.). Some fuels such as propane are bought and sold in gallons. What one needs to know for a comparison is how many Btu’s are in a gallon of propane? The answer is about 91,600 Btu/gallon (this varies a tiny bit between batches of propane). Fuels like diesel have about 140,000 Btu/gallon and gasoline has about 120,000 Btu/gallon.

Figure 1. Fuels with different energy content per volume.

Sometimes the fuels are described as Btu’s per pound (or ton). This is especially true for solid fuels such as coal and biomass (wood, corn, grasses, etc.). Liquid fuel is measured in pounds and can quickly be converted to gallons if the fuel density is known. This variety of ways to describe fuels can be confusing, but total Btu’s or MMBtu’s can be achieved at some point.

Electrical energy is obviously quite different than fuels. In the end, it can be used for the same types of tasks as fuels and can be compared. Electrical energy is described by Kilowatt-hours, which can be directly converted to Btu’s if describing heat energy (1 kWh = 3,412 Btu).

Equipment Efficiency

The next topic to examine when comparing energy costs is the efficiency of the equipment where the energy is utilized (See Figure 2.). Equipment efficiency can make a very big difference in the actual amount of energy used. For example, electric resistance heating is efficient (more than 95 percent), compared to an old natural gas heater (maybe 70 percent) – however, the cost of electricity is usually much more per Btu.

Figure 2. Energy Efficiency (energy conversion device could be a heater, for example).

If the cost for a type of energy is high enough, the difference in end-use efficiency may not be enough to overcome the price difference. This is usually the case with electric resistance heating compared to natural gas heating. On the other hand, electric heat pumps use a technology that allows the electricity to “move” a large amount heat to overcome much of this disadvantage. The other possibility is that the efficiency of the equipment is so low, even inexpensive fuels end up costing more in the long term than the alternative. This situation is common with wood, or biomass, heaters.

How is the efficiency of the equipment determined? If the equipment is new and installed properly, the manufacturer’s estimate of efficiency can be used. If the equipment is old or neglected, an estimation of the efficiency must be used for a measurement to be calculated. Old furnaces might have been 70 percent efficient when they were new many years ago. But if poorly maintained, this furnace efficiency could drop to as low as 50 percent. This is a bit of a judgement call without measurement. Keep in mind that leaky, old duct work and clogged filters also lower the overall equipment efficiency.

Energy Cost Comparisons

Now that a common energy unit (Btu’s) is achieved, and the equipment efficiency is determined, the energy costs can be examined. This is described this here, but you can easily experiment with the numbers in a simple online calculator described below.

Prices for fuels will be in dollars per MMBtu, MCF, Therm, Dekatherm, gallon, pound, ton, etc. These prices can vary quite a bit over a short time span. The following energy prices are given only as examples. Natural gas might cost a total of $6.00 per MMBtu (MCF). This would be $0.60 per Therm. Electricity might be $0.11 per kilowatt-hour (kWh). Propane might be $2.50 per gallon. Use the total “delivered” price of the energy (including all pertinent charges) to get an accurate comparison. The situation is the same with electricity – what is the total cost per kWh delivered (for example, last month)? Call up the utility and ask for the total delivered cost per unit (kWh, therm, etc.).

For solid fuels such as wood or coal, the units might be dollars per pound, ton or cord. The energy comparison spreadsheet on the website below will do the conversions to bring all energy sources to the final of dollars per MMBtu.

One last thing to consider before comparing the cost per MMBtu is the equipment (i.e., heaters, etc.) efficiency. Basically, the more efficient the equipment is – the closer you get to being able to use all the energy you paid for. Or, another way to look at it is, if a heater is very inefficient – the actual costs per energy unit will be high.

The final answers will be in dollars per MMBtu. Now quickly compare costs to see what energy source is the least expensive. When experimenting with the online calculator, these concepts will become fairly easy to understand. Note that this analysis does not give energy costs during a season – just a snapshot of the relative costs of energy sources.

Online Spreadsheet

Access our online energy cost calculator. When opening the webpage, look at the bottom-left links for “ENERGYCOST Calculator.” Open that link, and a spreadsheet table with electricity and various fuels will open (see Figure 3). On the left is the energy type. Pick the energy types to compare. The next column to the right is the average energy content of that fuel (or electricity). Leave that column as it is, unless a more accurate number is available. The third column to the right is the energy cost column. Enter the most current prices for the types of energy. By experimenting with higher and lower prices, costs can be determined if prices increase or decrease. The forth column to the right is the equipment efficiency column. This is probably the most subjective of the numbers. If unsure and do not want to guess equipment efficiency, simply use the default values here. Keep in mind that the default values are averages of equipment in good working order. Your equipment may be better (new, high efficiency) or worse (older, poorly maintained). Again, experiment with the numbers. The final column to the right is the cost per million Btu (MMBtu). This is the “final answers” column where the costs between the fuels can be compared1.

For example, At 85 percent efficiency and $1.80 per gallon for propane and $0.70 per Therm for natural gas, the costs per MMBtu are $8.24 for natural gas and $23.12 for propane. These prices can vary, but the lower cost energy in this particular example (all other things being equal) is natural gas.

Try experimenting with costs and efficiencies. The answers are fairly enlightening and help to clarify the differences between energy sources. Yearly cost savings are a much more involved calculation and are related to seasonal temperatures and other factors. Feel free to contact the authors with any questions.

| Fuel | Energy Content | Unit Price | Heat Conversion Efficiency | Cost Per Billion BTU | |

|---|---|---|---|---|---|

| Poultry Litter | 5,000 BTU/lb | $40.00 /ton | 60 % | $6.67 | |

| Bio- Diesel (B99=100)* | 120,000 BTU/lb | $2.00 /gal | 85 % | $19.61 | |

| Kerosene | 135,000 BTU/gal | $2.20 /gal | 85 % | $19.17 | |

| #2 Fuel Oil | 139,400 BTU/gal | $2.20 /gal | 80 % | $19.73 | |

| Propane | 91,600 BTU/gal | $1.80 /gal | 85 % | $23.12 | |

| Natural Gas | 100,000 BTU/therm | $0.70 /therm* | 85 % | $8.24 | |

| Electricity - Resistance | 3,412 BTU/kWh | $0.11 /kWh** | 100 % | $32.24 | |

| Electricity - Heat Pump | 3,412 BTU/kWh | $0.11 /kWh** | 300 % | $10.75 | |

| Coal | 13,100 BTU/lb | $200.00 /ton | 75 % | $10.18 | |

| Firewood-Hardwood | 24,000,000 BTU/cord | $200.00 /cord | 60 % | $13.89 | |

| Wood Pellets | 8,200 BTU/lb | $275.00 /ton | 80 % | $20.96 | |

| Shelled Corn | 6,970 BTU/lb | $4.00 /50 lbs | 75 % | $13.66 |

Φ Based on Penn State Extension Energy Cost Calculator

* Being Used as heating fuel - not transportation.

** Enter the price of natural gas as the price per therm. If your price for natural gas is based on $ per 1,000 cubic feet or MMBtu, divide that number by 10 to enter above. For example, if your cost for natural gas is $8.50 per 1,000 cubic feet, then divide by 10 and enter $0.85 as your price per therm.

*** Enter the price of electricity in dollars. An electricity price of 11 cents per kWh, for example, needs to be entered as $0.11.

Figure 3. Energy Cost Calculator.

Other Costs to Consider

Knowing the relative costs of energy sources makes for informed decisions. However, there may be other factors to consider. One is the equipment cost if installing new equipment. For example, if replacing an old heater with a higher efficiency unit, money will likely be saved on energy bills but the cost of the new equipment must be considered.

Natural gas is usually cheaper than propane on an energy basis, but if the natural gas is not available, propane may be the least expensive heating fuel available. The same can be said of heating oil. In the real world – a lot depends on what is available.

For solid fuels one needs to consider the “cost of convenience.” If considering switching to a log wood heater, the activity involved in moving wood around on a daily basis should be considered. What is this activity (or lack of it) worth?

Summary

With the online calculator you can make informed decisions about energy costs. If there is a desired fuel not on the calculator – call the authors and it will be discussed in person.

Not all included renewable energy sources such as small wind or solar systems are included in this calculator. The economics of these systems tend to be “first cost and maintenance” versus monthly costs. Therefore, the average monthly or yearly costs depend heavily on the life of the systems. There is a wide variety of durability for these systems, ranging from poor to good. Therefore, they do not lend themselves easily to this particular spreadsheet type of energy cost comparison. In the future these systems will be compared with conventional fuels.

1 Calculator Based on Penn State Extension Website: extension.psu.edu/online-energy-selector-tool