The Hobby Greenhouse

- Jump To:

- Attached Lean-To

- Attached Even-Span

- Freestanding

- Cost

- Locating the Greenhouse

- Designing the Greenhouse

- Greenhouse Width

- Greenhouse Length

- Greenhouse Height

- Fiberglass Greenhouses

- Plastic Greenhouses

- Potting Shed/Workroom

- Greenhouse Management

- Shading the Greenhouse

- Removal of Shading Compound

- Inside Maintenance

- Weatherproof Wire

- Associations

- Oklahoma Supply Companies

A greenhouse gives a homeowner an opportunity to grow plants year-round in a controlled environment. While a greenhouse can be either a substantial or nominal investment, success as a hobby greenhouse grower will depend on the degree of environmental control that can be maintained in the structure. Environmental controls can be expensive, and as most other hobbies, home greenhouses require a financial commitment.

The first step would be to accurately assess greenhouse requirements. Would a cold frame, hot bed, or window greenhouse meet the requirements, or is more growing space required? (It seems that regardless of the size selected, the structure will be too small eventually). Larger greenhouses (over 300 sq. ft.) cost less per square foot of useable space than smaller ones, but cost more initially and cost more to operate. Greenhouses are available in a large variety of shapes. Select the style that will harmonize with other features on the proposed site.

The greenhouse may be a free-standing structure, which generally will provide more growing space and flexibility to be placed anywhere on the property, or a lean-to structure attached to a wall of the home, garage, etc. Lean-to models are frequently less desirable because there are limitations on where they can be placed around the home. Preferred exposures are east and south. Regardless of the basic design, however, the greenhouse must receive a minimum of five to six hours of unobstructed light during the winter months.

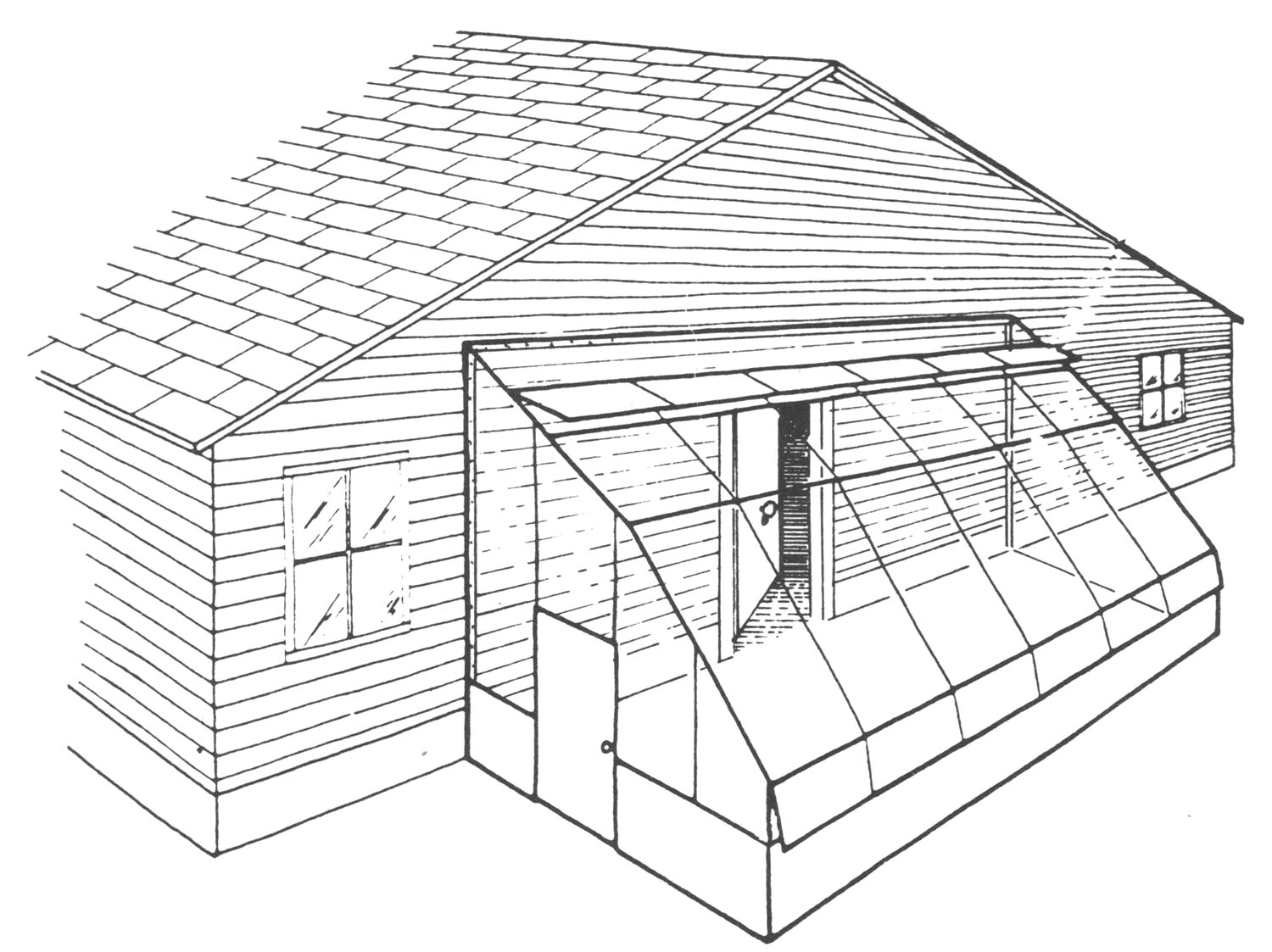

Attached Lean-To

A lean-to greenhouse is built against a building, using the existing structure for one or more of its sides. It is usually secured to a house, but may be attached to other buildings (Figure 1). The greenhouse is limited to single or double-row plant benches with a total width of 7 to 12 feet. It can be as long as the building to which it is attached. The advantage of the lean-to greenhouse is that it usually is close to available electricity, water, and heat. The lean-to has the following disadvantages:

- Limited space.

- Limited light.

- Limited ventilation and temperature control.

The least expensive type is a window mounted greenhouse. It allows space to grow a few plants at relatively low cost for heating and cooling. This reach-in greenhouse is available in many standard sizes, either in single units or tandem arrangements for large windows. Only simple tools are needed to remove the regular window from the frame and fasten a prefabricated window greenhouse in its place.

Figure 1. Attached Lean-to Greenhouse. This structure is very convenient since it is placed close to existing utilities.

Attached Even-Span

The even-span greenhouse is the standard type—the style generally visualized when thinking about a greenhouse. The even-span greenhouse is similar to a freestanding structure, except that it is attached to a house at one end. It can accommodate two or three rows of plant benches. Attached even-span greenhouses cost more than lean-to types, but have greater flexibility in design and accommodate more plants.

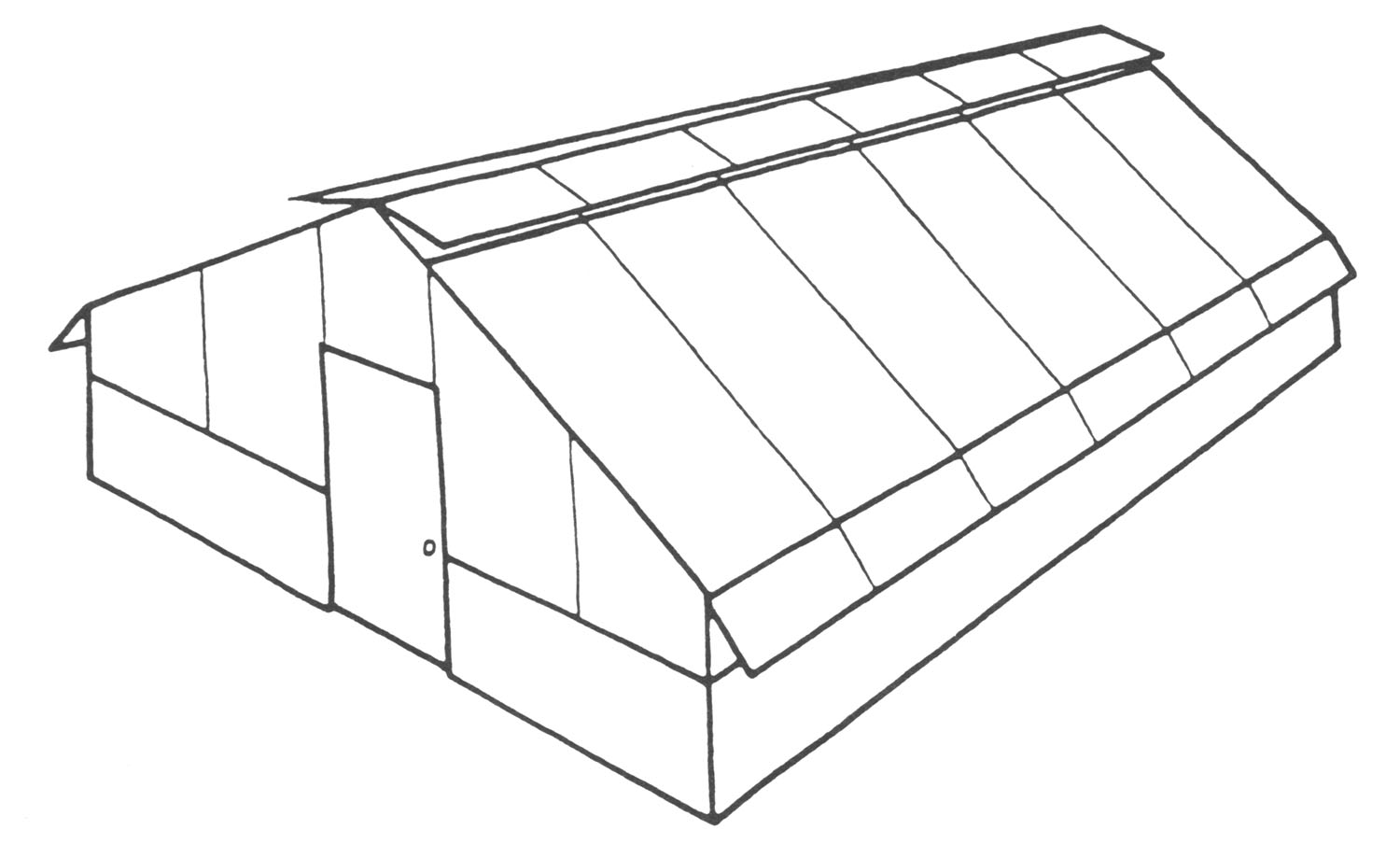

Freestanding

The freestanding greenhouse is a separate structure and consists of sidewalls, end walls, and gable roof (Figure 2). It is assembled similar to an even-span, except that a freestanding greenhouse is set apart from other buildings, allowing full exposure to the sun. It can be made as large or small as desired.

Figure 2. Freestanding Greenhouse. This structure does what its name implies; it stands alone.

The freestanding greenhouse is more easily adapted to the builder’s ideas of location, size, and shape than attached greenhouses. It also provides more light, but requires more heat at night because of the additional exposed surface area. Separate heating and cooling systems will be necessary.

Cost

The lowest cost per square foot of growing space is available in a 17 to 18-foot wide even-span greenhouse. It will house two side benches, two walks, and a wide center bench. The lowest total cost for a greenhouse is a 7 to 12-foot wide lean-to house with double-row benches and a central walk. Keep in mind that a lean-to greenhouse has less glass or other exposed covering; therefore, heating costs are less than for a free standing greenhouse.

Locating the Greenhouse

After deciding on the type of greenhouse desired, its placement will need to be determined. An ideal site for a greenhouse would be well drained, nearly level, and with full exposure to sunlight. It would slope slightly to the south and have a windbreak on the side of the prevailing wind.

The first choice for a greenhouse site should be on the south or southeast side of the house in a sunny location. The east side is the second best location, since it will capture the most November to February sunlight. The next best locations are the southwest and west, and the north side is the least desirable location.

A greenhouse can be placed where it will be partly shaded during the summer, when a reduction in light is desirable. Be sure the greenhouse is not shaded too heavily, and take into account the possibility of falling limbs that can damage the greenhouse.

Some plants will grow in a greenhouse in any location. However, types of plants which can be grown will be limited if the greenhouse is not placed in the best possible location.

Sometimes a greenhouse can be placed against a door, window, or basement entrance of the house. This allows heat from the house to enter the greenhouse, makes the greenhouse more accessible, and saves on construction costs. The home heating bill, however, will increase significantly. With an L-shaped house, the cost of two greenhouse walls can be saved by building the greenhouse in the “L.”

Wind protection may be more important than whether the greenhouse runs north and south or east and west. Protect the greenhouse from winds by locating it so existing buildings will shield it, or by providing it with a windbreak hedge or fence.

Designing the Greenhouse

Determine the exact dimensions for the greenhouse before starting to build. Width is the most important dimension; it will not be changed during the life of the greenhouse. Length can be increased if more space is desired.

Greenhouse Width

Determine the width of the greenhouse by adding the widths of the plant benches and the walks. Allow approximately six inches for walls at either side and two inches for air-circulation space between the sidewalls and the benches.

Side benches are serviced from only one side and should be no wider than one’s reach. For some people, this will be two feet; for others, perhaps as much as three feet. Center benches are serviced from both sides and, thus, can be as wide as six feet. They should be narrow enough to permit one to work comfortably.

Determine the width of the walkways according to their intended use. If they will be used only as a place to stand while servicing the benches, 18 or 19 inches is sufficiently wide; however, if a wheelbarrow will be brought into the greenhouse, the width must be greater. Wide walks, e.g. 24 to 30 inches, will allow easy passage for visitors who may not be used to walking between rows of plants.

Should a disabled individual confined to a wheelchair desire access, special design specifications should be kept in mind. Access walks to the greenhouse (if freestanding) need to be at least four feet wide, with a grade of no more than five percent (6 inches every 10 feet). Obviously, these wide entrances and paths throughout the structure will influence the width of the greenhouse.

Greenhouse Length

Determine the length of the greenhouse by dividing the total number of plants to be grown in the greenhouse by the density at which they can be spaced per linear foot of bench. For example, assume a freestanding greenhouse with two 30-inch deep side benches and one 48-inch deep center bench. Calculate the number of plants that could be grown per linear foot of bench space. Thus, if 500 plants are to be grown, and it is calculated that each side bench could grow five plants per linear foot, and the center bench could grow seven plants per linear foot, i.e. a total of 17 plants per linear foot, the greenhouse would need to be nearly 30 feet long, i.e. 500 divided by 17.

Greenhouse Height

The height of the greenhouse depends on the desired height to the eave. An eave height of 5 feet is satisfactory for side benches with low-growing plants. For tall plants, an eave height of 6 or 7 feet is needed. The pitch of the roof should be 6 in 12 (approximately 27 degrees). The eave height, the distance from the sidewall to the center of the greenhouse, and the roof pitch will determine the height of your greenhouse at the center. The height of the greenhouse should be equal to the eave height plus one-fourth the width of the greenhouse.

For instance, in an even-span greenhouse 18 feet wide, the distance from the sidewall to the center of the greenhouse is 9 feet. The difference in height between the center of the greenhouse and eave will be one-half of 9 feet, or 4 1/2 feet. If the eave is 5 feet high, the greenhouse should be 9 1/2 feet at the center.

Fiberglass Greenhouses

Fiberglass is lightweight, strong, and practically hailproof. Corrugated panels or flat fiberglass are available. Poor grades of fiberglass will discolor, which reduces light transmission. A good grade, on the other hand, may make a fiberglass greenhouse as expensive to build as a glass house. If fiberglass is used, select the clearest grade. Do not use colored fiberglass.

Plastic Greenhouses

Plastic greenhouses are increasing in popularity because:

- Construction cost per square foot is generally one-sixth to one-tenth the cost of glass greenhouses.

- Plastic greenhouses can be heated as satisfactorily as glass greenhouses.

- Plants grown under plastic have the same quality as those grown under glass.

- Plastic greenhouses are sometimes considered temporary structures and usually carry a low assessment rate for tax purposes, or may not be taxed at all.

Plastic greenhouses can be made of polyethylene (PE), polyvinyl chloride (PVC), copolymers of these materials, or other readily available clear films. Plastic coverings will have to be replaced more frequently than other glazings.

Potting Shed/Workroom

A separate workroom or small building attached to the greenhouse can be advantageous. Potting, seed sowing, soil mixing, etc. can be carried out while this room also serves as storage area for pots, growing media, stakes, pesticides, etc. Keep this building attached to the greenhouse so that during cold weather plants can be moved freely about without worry of freeze damage. Tropical plants may be injured or killed by temperatures less than 50ºF.

The shed can be equipped with a bench for potting along with containers or bins to store media ingredients, such as peat moss, perlite, sand, etc. A small closet that can be locked is a good idea for the pesticides, particularly when pets or small children are present. Lastly, a sink with running water should be considered to simplify washing of pots, syringing of plants, and other chores that may be necessary.

Greenhouse Management

Heating

Many types of heaters and heating systems are satisfactory for greenhouses. Consider the initial cost, operating expenses, and available fuel. Greenhouses can be heated efficiently with coal, electricity, gas, or oil. A space heater, a forced-air heater, a hot-water or steam system, or electric radiant heaters can be used. Radiant heat lamps over plants can be combined with soil heating cables under plants.

The required capacity of the heating system will depend on the size of the greenhouse, the insulating or “R” value of the glazing material, and the maximum difference between inside and outside temperatures.

Heating systems are rated in British thermal units (BTU) per hour. The company supplying the greenhouse should be able to configure an appropriately sized heating system.

First, find the temperature difference. This is the difference in degrees Fahrenheit between the lowest outside temperature and the minimum temperature to be maintained inside the greenhouse. For instance, to maintain a minimum inside temperature of 60ºF with the coldest expected night temperature of -10ºF, the temperature difference is 70ºF. Next, calculate the number of square feet of exposed glazing in the greenhouse. Do not forget to add the areas of the sides and ends to the area of the roof.

Multiply the temperature difference by the number of square feet. For example, if a 20 by 100-foot greenhouse has a total of 3,400 square feet of exposed plastic, multiply 3,400 by 70 (the temperature difference) yielding 238,000.

Now, if the greenhouse is covered with two layers of plastic or glass, multiply the 238,000 by 0.8. If it is covered with only one layer, multiply by 1.2. This will calculate the required BTU per hour capacity of the heater. In the example, a two-layer greenhouse would be:

238,000 x 0.8 = 190,400 BTU per hour

The type of heating system selected will depend on funds available to spend. The four types are:

- Space heater. For low-cost heating of small greenhouses, use one or more ordinary space heaters. (WARNING: Gas, oil, or coal fired heaters need a fresh air supply for combustion as well as exhaust venting to avoid carbon monoxide and ethylene accumulation.) Fans are also needed to improve circulation. In kerosene heaters use only high-grade (low sulfur) kerosene to avoid sulfur dioxide emission; the need for high ignition temperature is important to avoid carbon-monoxide and ethylene buildup.

- Forced-air heater. The best system for heating a small greenhouse is a forced-air furnace with a duct or plastic tube system to distribute heat. A thermostat can be used to control the temperature in the greenhouse.

- Hot-water or steam heater. A hot-water system with a circulator or a steam system linked with automatic ventilation will give adequate temperature control. In many areas of Oklahoma, natural gas is readily available at a low cost. This fuel is ideal for hot-water or a central steam system. Steam has an advantage in that it can be used to pasteurize growing beds and potting soils. Hot water and steam systems provide more precise control over temperature fluctuations and tend to operate more quietly than forced-air systems.

- Electric heater. Overhead infrared heating equipment, combined with soil cable heat, provides a localized plant environment that allows plants to thrive, even though the surrounding air is at a lower than optimal temperature. Electric resistance type heaters are used as space heaters or as an integral part of a forced air system.

Important: Consider investing in a temperature alarm system which alerts the hobbyist to any power failures. These thermalarms are worth the investment, particularly when growing expensive plants such as orchids or other highly prized tropicals.

Ventilation

Even during cold weather, a greenhouse can get too warm on bright, sunny days. Ventilation equipment, therefore, should be built into the greenhouse to control temperatures and humidity in all seasons. When using hand-operated roof vents, frequent temperature checks will be required. As outdoor weather changes, sashes must be opened and closed manually to keep plants from getting too hot or too cold.

Automatic ventilation eliminates manual work and is the best way to cool a greenhouse. If your greenhouse has roof vents, for example, a thermostat and electric motor will open and close the vents. Temperature sensitive hydraulic pistons can be used to open and close small side and roof vents. Since they offer automatic ventilation without relying on electricity, proper ventilation will be maintained, even during electrical outages. Fresh outside air is brought in through the side vents via convection as the warm air flows out through the roof vents. In addition to cooling the greenhouse, the change of air improves growing conditions. Responding to this air transfer, the thermostat will turn off and on to keep desired temperatures for plants. Circulating and exhaust fans provide good ventilation and are needed in both large and small greenhouses. Exhaust fans should be large enough to change the air in the greenhouse once every minute. To accomplish this, the capacity of the fan in cubic feet per minute at 1/8-inch static pressure should equal the volume of the greenhouse. The approximate volume can be calculated by multiplying the floor area by 7.

If the greenhouse is high enough, place the exhaust fan and the motorized intake louvers above the doors at opposite end-walls. This will exhaust the hottest, most humid air and prevent a direct draft on the plants near the intake.

Fan and duct ventilation can also be used for automatic greenhouse heating and ventilation. Plastic ducts are suspended by wires or straps from the roof of the greenhouse. The fan-heater-louver unit gives positive air flow, and the polyethylene duct distributes the incoming air evenly throughout the house.

Shading the Greenhouse

When protection from the sun is needed, use rollup screens of wood or aluminum, polypropylene shade cloth, vinyl plastic shading, or paint-on materials. Rollup screens are available with pulleys and rot-resistant nylon ropes. These screens can be easily adjusted from outside the greenhouse, as weather and sunlight vary.

Polypropylene shade cloth can be purchased in custom sizes, in black or green, and in 30 to 100 percent light transmission. These fabrics can be secured with rope or hooked onto the greenhouse by grommets woven into the binding.

Vinyl plastic shading is made of a flexible film that reduces light from 55 to 65 percent. The material comes in rolls and installs easily against the glass inside your greenhouse. To apply, just wash the glass with a wet sponge, then smooth the plastic onto the wet glass. When smoothed into position it adheres to the glass. It can be pulled off and used repeatedly.

Shading compound can be applied on the outside of glass greenhouses. Do not use shading compounds (whitewash) on materials other than glass. They may harm the glazing (covering) and may not be easily or totally removable. Shading compound can be thinned with paint solvents. It comes in either white or green. Shading compound that mixes with water can also be used. The following is a homemade recipe for whitewash. Mix 5 pounds hydrated lime with 3/4 gallon water and allow this mixture to age overnight. Then dissolve 1 pound of common salt with 1/5 pound of zinc sulfate in 1/5 gallon of boiling water. Allow to cool, and then mix with lime paste and stir well. Lastly, add 1/5 gallon of sweet skimmed milk and again stir. Add water and keep stirring until desired thickness is reached.

A lime paste can be mixed by using 50 pounds of hydrated lime with 6 gallons of water, or 38 pounds of quick lime with 8 gallons water. An even more simplified formula is as follows:

1 part white latex paint to 10 parts water provides heavy shading; whereas,

1 part white latex paint to 15 to 20 parts water gives moderate or standard shading.

Removal of Shading Compound

As fall approaches, maximum sunlight will be needed again for greenhouse grown plants. Much of the shading compound may be worn off by this time, depending upon the solution applied. However, any remaining compound should be scrubbed off clear glass to allow maximum light penetration.

Cooling can be a Problem

Cooling a greenhouse in Oklahoma is difficult. Two typical methods of cooling are used in the summer. The first method is to reduce the light intensity passing through the covering material by using a shading compound, a shade cloth, or wood slats on the outside of the greenhouse. The second and most effective method of greenhouse cooling is accomplished by using an evaporative cooler. This system works by pulling outside air through a film of water thus cooling the air 15º to 20ºF by loss of heat through evaporation. The cool air is pulled through the greenhouse by a fan. Evaporative coolers work best at lower humidities. Most hobby greenhouse supply companies have easy-to-install coolers made for hobby greenhouses. Such a system should receive equal priority to a heating system. The cost of operating an air conditioner to cool a greenhouse would be prohibitive and would likely reduce humidity in the greenhouse to less than optimal levels.

The ideal temperature range for most greenhouse crops is 55º to 60ºF for night temperature, and 70º to 75ºF for day temperature. The day temperature should be 5º to 10º higher than the night temperature on a cloudy day, and 10º to 15º higher on a sunny, bright day. It is essential that a thermostat be located in the greenhouse in a central location, at plant level, and away from direct exposure to sunlight. Do not rely on the home cooling system with a thermostat in the living area to cool the greenhouse. Cooling the greenhouse may also be thermostatically controlled. When the temperature exceeds the desired temperature, the thermostat activates a small electric motor which opens a vent, turns on an exhaust fan, and turns on an evaporative cooler. During summer months, an evaporative cooler will be necessary to keep the temperature close to the optimum level; at other times of the year, an open vent or exhaust fan will dissipate excessive heat effectively.

Inside Maintenance

It is very important that the greenhouse be kept as clean as possible. When this is overlooked, diseases and insects can rapidly become a major problem. Keep all paths and floors free of weeds and debris. Don’t allow standing water or muddy floors to exist. Consider gravel, concrete, or even bark floors for cleanliness and drainage. Keep dead and dying growth pruned from plants, regularly. Many common sense practices already practiced in the home are also applicable in the greenhouse. Avoid the temptation to overcrowd the benches with plants, as this will prevent disease or insect problems.

Weatherproof Wire

Always weatherproof wire for all outside wiring. Wire size depends upon the distance to be covered and the electrical load on a circuit. Use approved terminal equipment and follow safe wiring practices. All wiring must conform to local wiring codes. It is worth the money spent and peace of mind to consult a qualified electrician before building a greenhouse.

Contact your county Extension educator for help in locating a few of your neighbors who have hobby greenhouses. Visit them to learn about their problems so that you can choose the best greenhouse to suit your needs.

Check local building codes and zoning laws before starting construction.

Any good book on houseplant care gives guidelines or suggestions on what grows well in a greenhouse. Most growers are very surprised to see how much easier plants can be grown in the ideal environment a hobby greenhouse provides. Refer to OSU Extension fact sheet HLA-6411 and HLA-6425 regarding houseplant care and annual flowers. Guidelines within are applicable to greenhouse culture. Also, readers interested in a commercial greenhouse operation should refer to OSU Extension fact sheet HLA-6700, HLA-6701, and HLA-6703.

Associations

Hobby Greenhouse Association

Oklahoma Supply Companies

Acme Engineering & Mfg. Corp.

P.O. Box 978

Muskogee, OK 74402

(918) 682-7791

American Plant Products and Services, Inc.

9200 N.W. 10th

Oklahoma City, OK 73127-9722

(405) 787-4833

Mike Schnelle

Assistant Professor

Extension Ornamentals/Horticulture Specialist

Steven H. Dobbs

Extension Consumer, Floriculture Specialist

Douglas C Needham

Assistant Professor, Floriculture

John M. Dole

Assistant Professor, Floriculture