Stack Pattern Effects on Wind Forces in Open Buildings

How you stack hay in an open hay shelter can make the difference in whether the building survives a wind storm or gets blown away. Storm damage losses to Oklahoma farm homes and production buildings total into the millions of dollars each year. Some of these losses can be avoided or reduced without spending a cent. The purpose of this fact sheet is to explain how these losses can be minimized.

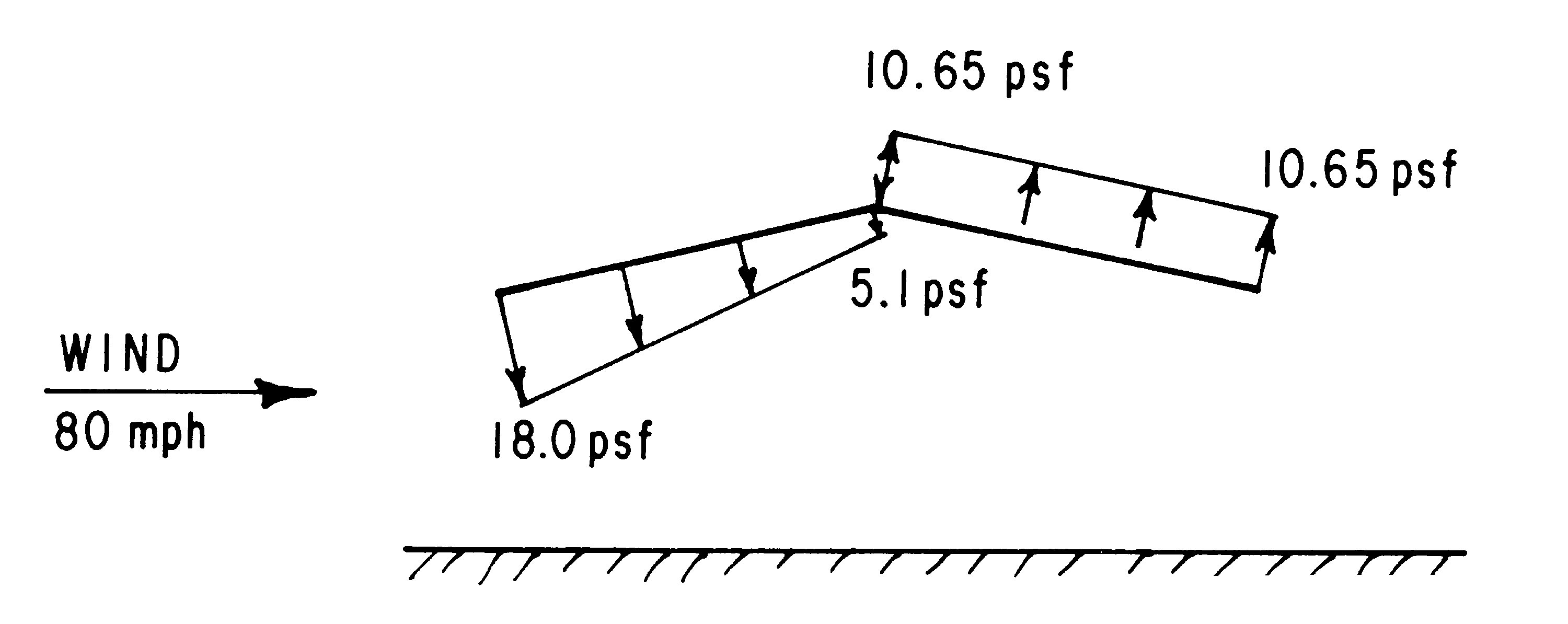

Hay shelters consisting of a roof and no side walls and machinery and other storage buildings of the same design are usually designed structurally for wind forces that occur when the building is either empty or full. When the building is empty, air flows both under and over the roof, causing downward forces on the windward roof and upward forces on the lee roof. When the building is stacked full, wind is blocked by the stored products and air is forced up and over the roof, causing uplift forces on both the windward and leeward roof.

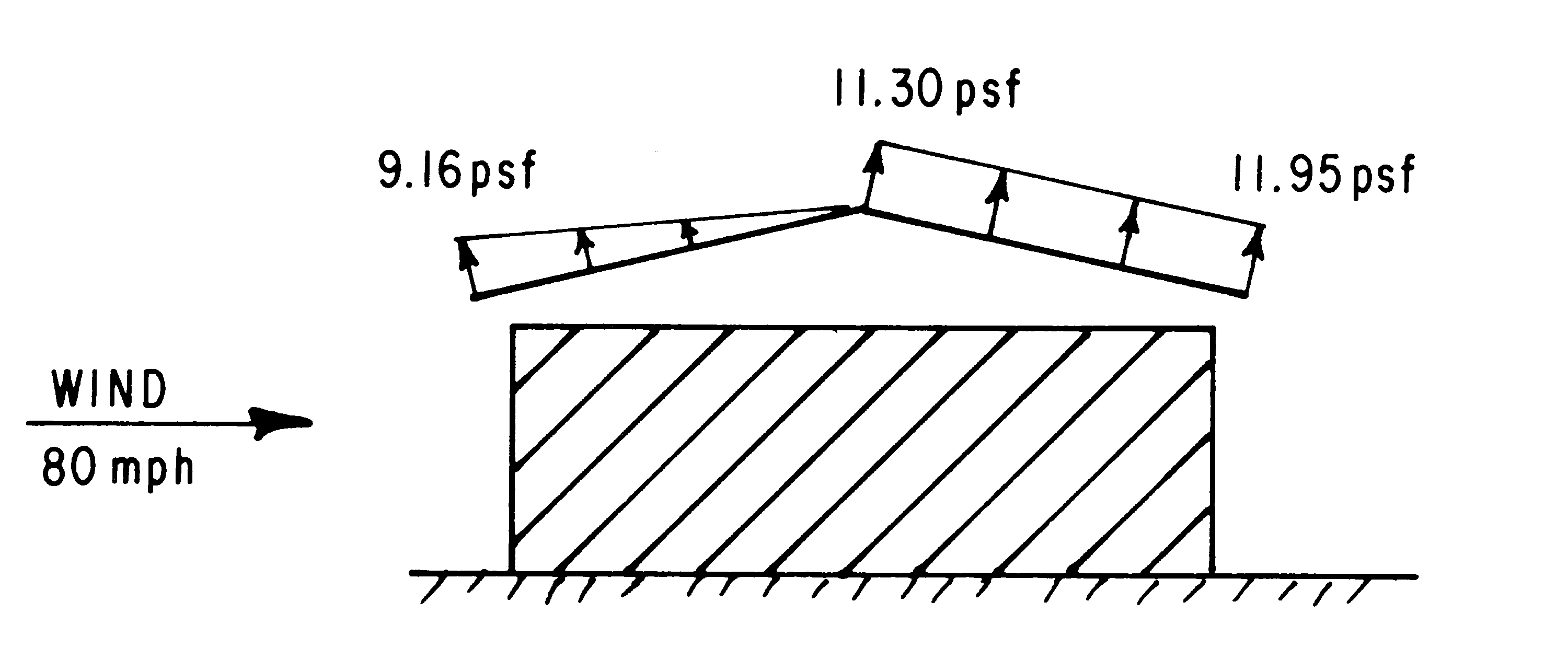

Figures 1 and 2 show the direction and magnitude of these forces for both empty and the full shelters for an 80 mph wind, the design wind velocity for most of Oklahoma. Wind forces on the roof average 10 to 11 pounds per square foot, with a maximum force of 18 pounds per square foot at the leading roof edge on the windward side.

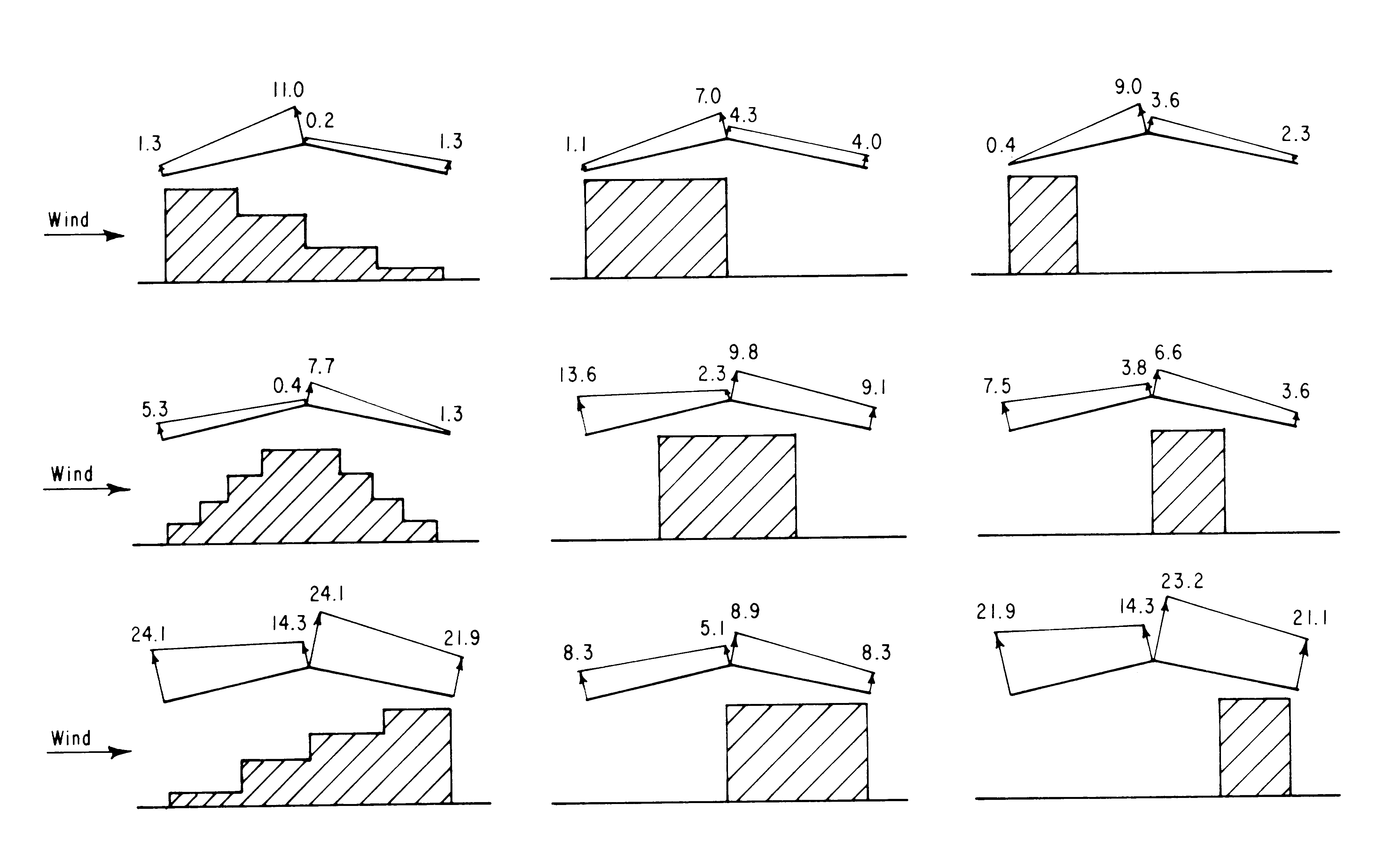

When a building is partly full, or partly empty, wind force patterns on the roof change drastically, as shown in Figure 3. Resulting wind forces for these stack patterns, obtained in wind tunnel tests, may partly explain the high loss that hay storage buildings have suffered in the past.

As can be seen from these illustrations, some stack patterns can cause pressure on the roof to double, a 100 percent increase over design forces. This occurs with NO increase in wind velocity, just changing the stack pattern. Such drastic increases in pressure on a roof are almost certain to result in a building failure, even for the best constructed buildings.

The wind forces of 10 pounds per square foot on roofs shown in Figures 1, 2, and 3 may not seem high. Even loads as high as 20 pounds per square foot for critical stack patterns may seem small. However, consider the total force they would represent on an actual building. For a 40-foot wide by 100-foot long hay shelter, the total design uplifting load for the roof of a shelter full of hay would be 20 TONS. For a partly full shelter with the most critical stack patterns, the load on the lee roof alone would be 20 TONS. When the numbers are applied to a real building, it isn’t difficult to see why buildings can fail.

Figure 1. Wind force direction and magnitude on the roof of empty hay or equipment shelter. Building configuration is for a 4/12 roof slope, building dimensions are 44 feet wide and 16 feet height at the eaves.

Figure 2. Wind force magnitude and direction on the roof of a hay shelter with hay stacked almost to the eaves.

Figure 3. Wind force magnitude and direction for selected bale stack patterns. All forces are upward forces and force is in pounds per square foot of roof surface. Wind directions is from left, as shown by wind arrow. Wind velocity is 80 mph.

High uplifting pressures on the roof result when stacks are at the lee side of the roof, trapping wind in the building. They can also occur when the stacks direct wind flow up against the roof, as with the step pattern. This latter pattern of storage is quite common and occurs when bales are pulled off in tiers as hay is fed.

Figure 3 also shows that, for the same 80 mph wind velocities, many stack patterns can reduce wind forces on the roof. Stacks centered in the building, stacks stepped up to the center from both sides, or stacks only on the windward side, can drastically reduce the wind load on the roof. These patterns result in wind forces on the roof well below forces the building was designed to resist.

Note, however, that some “safe” patterns become “critical” patterns when wind directions are reversed. Because high winds can come from any direction during a storm, the safest practice is to keep stacks worked in toward the center of the shelter as hay is fed or sold. This practice leaves room on the lee side to let the wind out that is let in on the windward side. Avoid critical stack patterns that increase wind loadings on the roof. Following these simple rules can make the difference between keeping and losing a shelter.

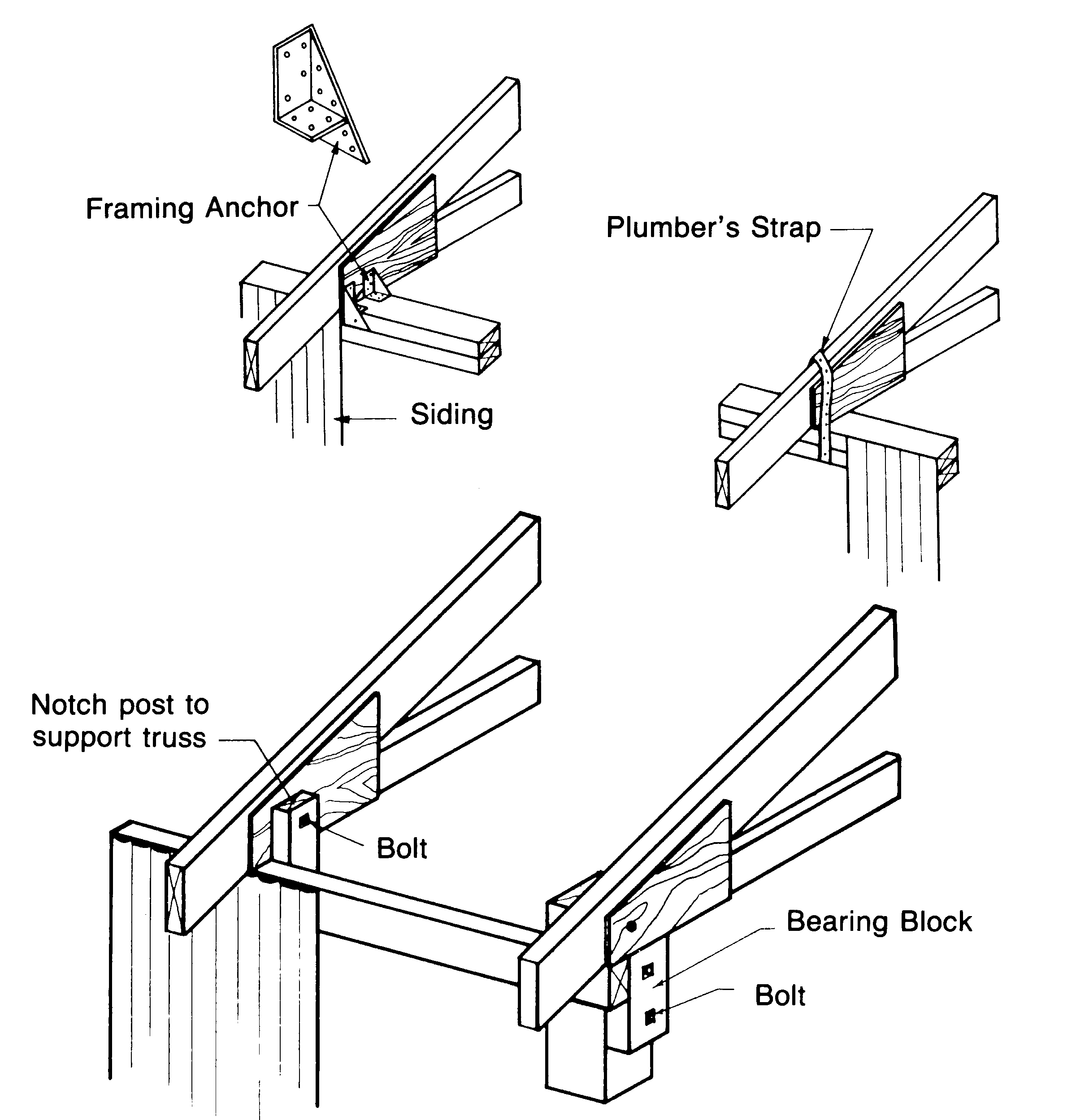

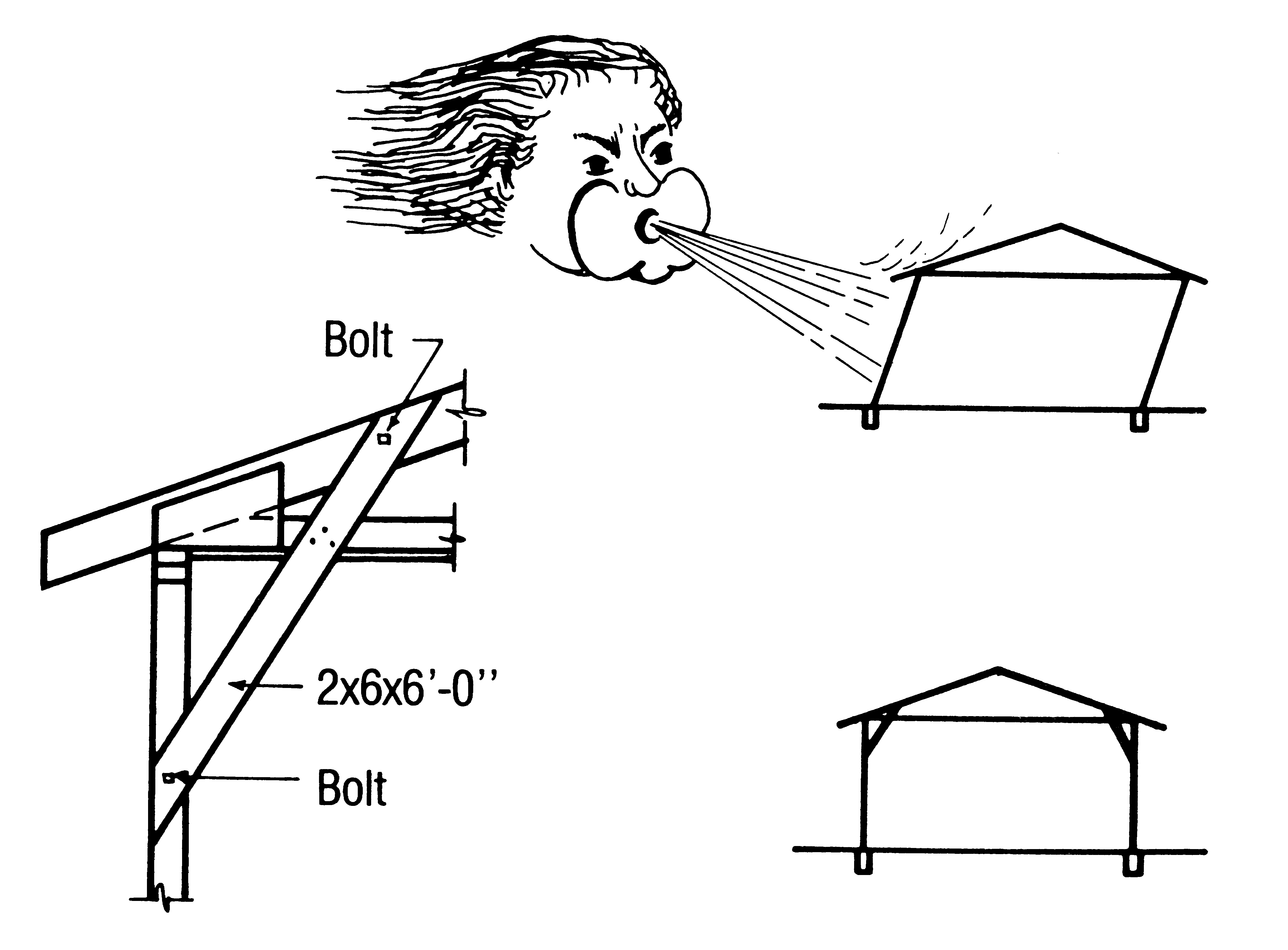

Obviously, another method of avoiding building losses is to use good construction practices. As shown in Figure 3, most critical wind forces are uplifting forces which tend to pull the roof off the frame and poles out of the ground. The direction of the force, upward, is opposite what many people expect.

To resist this upward force during high winds, the roof must be tied down all the way to the ground. Fasten roof frames and trusses or rafters to supporting members with tiedowns or storm clips. Fasten support members and beams or girders to framing poles with bolts or pole barn nails. See Figure 4. Add knee braces to increase the strength and stiffness of these joints. See Figure 5.

Figure 4. Truss anchorage.

Figure 5. Typical knee brace – 8 feet on center. Figures 4 and 5 courtesy Midwest Plan Service, Ames, Iowa.

Lastly, anchor poles in concrete when constructing new buildings instead of using tamped earth anchorages. Concrete anchorages are many times stronger than tamped earth in resisting uplift, and full, reinforced anchorages can increase the pole’s lateral stiffness in resisting racking of the frame.

These construction practices should be followed for all farm construction. The added cost is small. The added returns are great. They might even save your life, or the life of a member of your family.

Even though the results and examples given have been for hay barns with various stacking patterns, any machine or work shelter with combines, semi-trailer trucks, stacks of crates or pallets could cause similar storage patterns. Parking equipment or semi-trailers outside the building against the lee side could also cause critical roof loads by trapping the wind force under the roof.

To summarize, one can do two (2) things to minimize the chances of losing your hay shelter in a wind storm. First, avoid storage patterns that can cause high forces on the building. This will cost nothing but the time to plan hay stacking or hay removal. Second, use good construction practices when building a new shelter or reinforcing an existing shelter. The cost is minimal and the returns can be great. Remember, THIS IS ONE TIME YOU CAN DO SOMETHING ABOUT THE WEATHER.

George W. A. Mahoney

Associate Professor, Agricultural Engineering

Raymond L. Huhnke

Extension Agricultural Engineer