Sorghum Kernel Damage

Principal Sorghum Kernel Damage

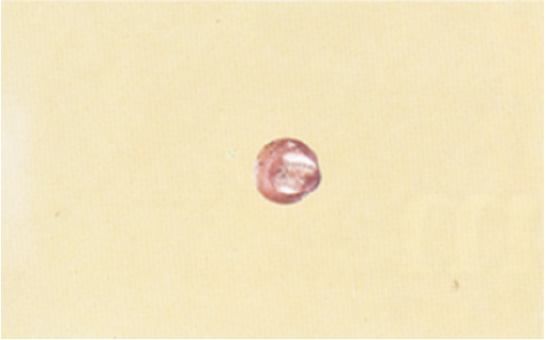

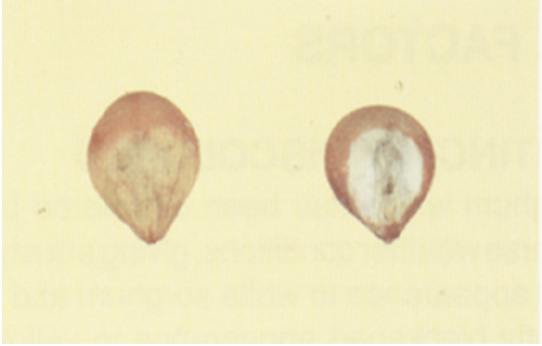

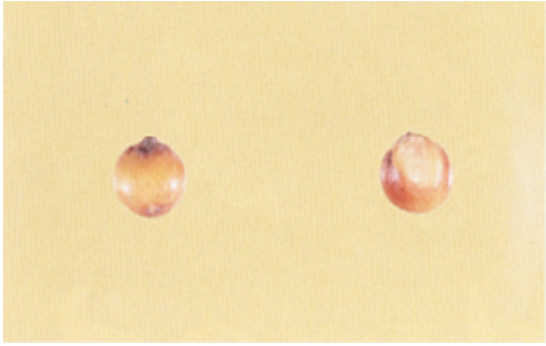

GERM DAMAGE (SCRAPE METHOD)

Kernels and pieces of kernels of sorghum which, after scraping, contain dark colored germs shall be considered damaged. Note: When scraping kernels of sorghum, the pericarp should be removed carefully; cutting too deeply will destroy the germ area.

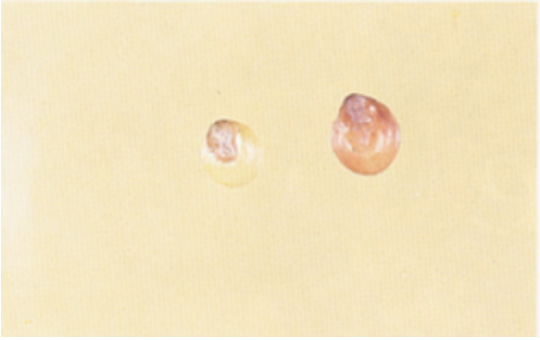

Germ Damage (Bleach Method)

Kernels and pieces of kernels of sorghum which, after bleaching, contain dark colored germs shall be considered damaged.

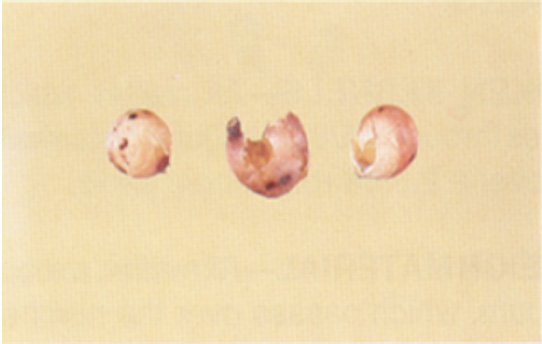

Ground and/or Weather Damage

Kernels and pieces of kernels of sorghum which contain dark stains or discolorations and have rough cake-like appearance caused by ground and/or weather conditions shall be considered damaged.

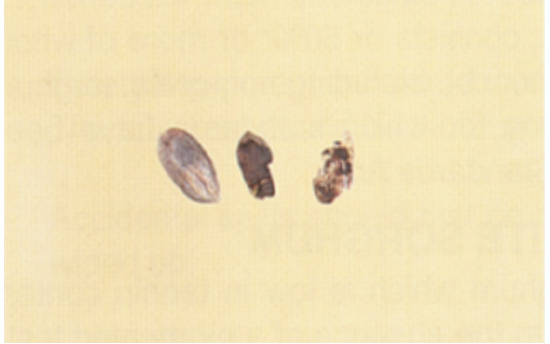

Heat Damage

Kernels and pieces of kernels of sorghum which are materially discolored and damaged by heat shall be considered as damaged. Note: It is necessary in most cases to cross section the kernels to determine if the color is creamy.

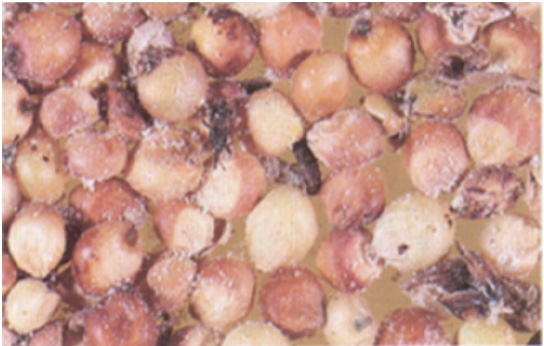

Surface Mold Damage

Kernels and pieces of kernels of sorghum containing surface mold shall be considered damaged. Note: Do not confuse mold with dark stains or discolorations caused by ground and/or weather conditions.

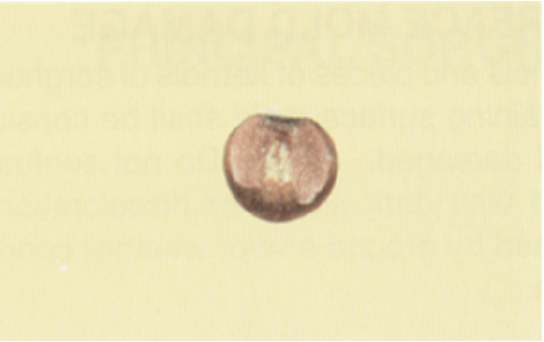

Internal Mold Damage

Kernels and pieces of kernels of sorghum containing mold, usually in the germ area under the bran layer, shall be considered damaged. Note: It is difficult to detect this condition; therefore, it is necessary to carefully observe the germ area for a slight blue discoloration. The bran layer should be lifted carefully so as not to destroy the evidence of damage.

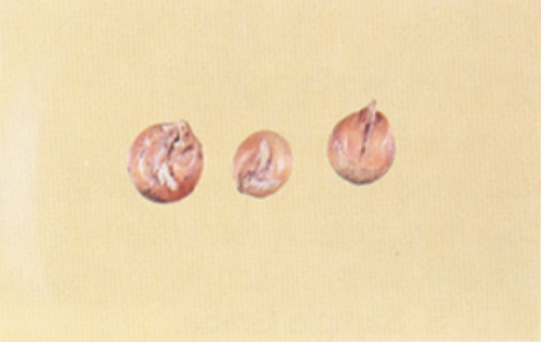

Sprout Damage

Kernels and pieces of kernels of sorghum in which the sprout definitely protrudes from the germ shall be considered damaged. In the practical application of this definition, the sprout must have split the germ covering and be 1) sticking straight up, or 2) extending out of the upper portion of the germ area, or 3) extending down over the tip of the kernel. Note: Kernels which have a split over the germ area, but which have no sprout protruding, shall be considered sound unless otherwise damaged.

Insect Damage

Kernels and pieces of kernels of sorghum which have been bored or tunneled by insects shall be considered damaged.

Purple Pigment Damage

Kernels and pieces of kernels which are materially discolored by purple pigment; the color must be intense and the coverage to the extent shown.

Appearance Factors

Distinctly Discolored

Sorghum which has been discolored by adverse weather conditions, giving a dusty,

gray appearance to white sorghum and a slightly blackened appearance to yellow or brown sorghum, shall not be graded higher than U.S. No. 3.

Badly Weathered

Sorghum which has been discolored by adverse weather conditions and has progressed to a point where many of the kernels are badly discolored shall be graded U.S. Sample Grade.

Other Grading Factors

Broken Kernels, Foreign Material, and Other Grains

Broken Kernels—All matter which passes through a 5/64 triangular-hole sieve and over a 2.5-64 round-hole sieve.

Foreign Material—All matter, except sorghum, which passes over the number six riddle and all matter other than sorghum that remains on top of the 5/64 triangular hole sieve.

Other Grains—Barley, corn, cultivated buckwheat, cinkorn, emmer, flaxseed, guar, hull-less barley, non-grain sorghum, oats, polish wheat, popcorn, poulards, wheat, rice, rye, safflower, soybeans, spelt, sunflower seed, sweet corn, triticale, and wild oats.

Dockage—All matter, including pieces of sorghum, that will pass through a 2.5/64 round-hole sieve by use of an approved device.

Special Grades

Infested

Sorghum that is infested with live weevils or other live insects injurious to stored grain. Sorghum is considered infested when the representative sample, or lot as a whole (stationary) or component sample (continuous loading/unloading of shiplots and barge lots), contains two or more live weevils, or one live weevil and five or more other live insects injurious to stored grain, or ten or more other live insects injurious to stored grain.

Smutty

Sorghum that has kernels covered with smut spores to give a smutty appearance in mass, or that contains 20 or more smut balls in 100 grams of sorghum.

Grade Requirements For Sorghum

| Grade | Minimum test weight per bushel (lbs) | Heat damaged kernels (%) | Total damaged kernels bushels (%) | Foreign material (%) | Broken kernels, foreign material, and other grains (%) |

|---|---|---|---|---|---|

| U.S. No. 1 | 57.0 | 0.2 | 2.0 | 1.5 | 4.0 |

| U.S. No. 2 | 55.0 | 0.5 | 5.0 | 2.5 | 7.0 |

| U.S. No. 3* | 53.0 | 1.0 | 10.0 | 3.5 | 10.0 |

| U.S. No. 4 | 51.0 | 3.0 | 15.0 | 4.5 | 13.0 |

U.S. Sample grade—

U.S. Sample grade is sorghum that:

- Does not meet the requirements for the grades U.S. Numbers 1, 2, 3, or 4; or

- Contains 7 or more stones which have an aggregate weight in excess of 0.2 percent of the sample weight, 1 or more pieces of glass, 2 or more crotalaria seeds (Crotalaria spp.) 1 or more castor beans (Ricinus communis L.), 3 or more particles of an unknown foreign substance(s), 7 or more cocklebur (Xanthium spp.) or similar seeds singly or in combination, 9 or more rodent pellets, bird droppings, or equivalent quantity of other animal filth per 1,000 grams of sorghum; or

- Has a musty, sour, or commercially objectionable foreign odor (except smut odor); or

- Is badly weathered, heating, or otherwise of distinctly low quality.

* Sorghum which is distinctly discolored shall be graded not higher than U.S. No. 3.

Definition Of Sorghum

Grain that, before the removal of dockage, consists of 50% or more of whole kernels of sorghum (sorghum bicolor L. Noench) excluding non-grain sorghum and not more than 10.0% of other grains for which standards have been established under the United States Grain Act.

White Sorghum

Sorghum which is low in tannin content due to the absence of a pigmented testa (subcoat) and contains not more than 2.0 percent sorghum of other classes. The pericarp color of this class is white or translucent and includes sorghum containing spots that, singly or in combination, cover 25.0 percent or less of the kernel.

Sorghum

Sorghum which is low in tannin content due to the absence of a pigmented testa (subcoat) and contains less than 98.0 percent white sorghum and not more than 3.0 percent tannin sorghum. The pericarp color of this class may appear white, yellow, pink, orange, red, or bronze.

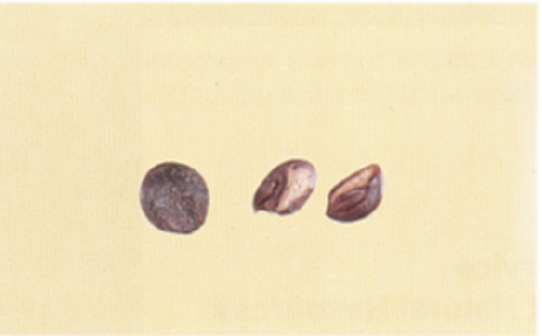

Tannin Sorghum

Sorghum which is high in tannin content due to the presence of a pigmented testa (subcoat) and contains not more than 10.0 percent non-tannin sorghum. The pericarp color of this class is usually brown, but may also be white, yellow, pink, orange, red, or bronze.

Mixed Sorghum

Sorghum which does not meet the requirements for any of the classes sorghum, tannin sorghum, or white sorghum.

Pericarp

The pericarp is the outer layers of the sorghum grain and is fused to the seed coat.

Sorghum Bleach Test

Caution

Any deviation from the steps producers outlined below may result in improperly bleached sorghum and could produce a hazardous condition

- Safety equipment should be worn while the bleach operation is in progress. The

lab area should be thoroughly cleaned once bleaching is complete. - Accidental spills should first be neutralized with vinegar before the liquid is

wiped up. - Avoid mixing the potassium hydroxide (KOH)-bleach solution used in this test

with chemical reagents or waste solutions associated with other tests. - When disposing of the (KOH)-bleach solution, wash the solution down the sink

drain with large quantities of water.

Bleach Procedure

- Place the representative portion of sorghum in the mixing jar.

- Add 15 grams of KOH pellets.

- Add 40 ml of bleach.

- Set stirring head on jar, place jar on mixer, and mix for 3 minutes.

- Pour the contents of the mixing jar into the tea strainer and rinse with warm tap water to remove the KOH-bleach solution.

- After rinsing, lightly tap the tea strainer against the edge of the sink to remove the excess water. Gently press the bottom of the tea strainer on a dry paper towel to remove any additional water.

- Place the sorghum on the dryer sieve and dry for 1 to 1 1/2 minutes or until the kernels are not tacky when picked up with a pair of tweezers.

- Remove the sorghum from the drying sieve and weigh the portion. The kernels with germ damage are now readily apparent. If the germ damage is not readily apparent, it is permissible to carefully lift the bran coat from over the germ area to make this determination.

Basis of Determination. Determine the class of sorghum, when necessary, on a bleached portion of approximately 15 grams after the removal of dockage, broken kernels, and foreign material removed by the 1.98 mm (5/64 inch) sieve. Use the following S/J mixer procedure to determine blends of Sorghum and Tannin sorghum. (Reference: Interpretive Line Slide (ILS) S-9.0, “Tannin sorghum (Bleached).”

Bleach Procedure. Similarities in the bleaching methods used in the determination for sorghum germ damage and class allow inspectors to effectively use the damage portion to screen samples for class. If the bleached damage portion contains darkened kernels similar to those depicted in ILS S- 9.0, bleach a separate portion according to the following procedures:

- Determine the percentage of white sorghum (ILS OF-33.0, “White sorghum”) present in

a

mixture before bleaching due to the difficulty of distinguishing between White sorghum and

Sorghum after bleaching. Recombine the sample before proceeding to the next step. - Place approximately 15 grams ± 1.5 grams of sorghum in the S/J mixing jar. Do not use

portions greater than 16.5 or less than 13.5 grams.

Acknowledgments

We wish to express sincere appreciation to representatives of the Wichita Field Office

of the Federal Grain Inspection Service for their assistance in revising this publication.

Authors

Dr. Kim Anderson

Department of Agricultural Economics

Cooperative Extension Service

Oklahoma State University

Roger Friedrich

Supervisory Physical Scientist

FGIS Technical Center, Kansas City, Missouri.

The Photographs are not official Federal Grain Inspection Service line prints; thus

it is

recommended that the pictures not be used for grading purposes.