Poultry Ventilation Fan Maintenance and Energy Savings

Introduction

Poultry house ventilation is typically the second largest energy cost behind winter propane heating. Modern tunnel ventilation houses require numerous large fan systems to provide year-round ventilation and to cool the flocks in the summer. Normal wear and the dirty environment in which these systems operate can result in a surprising loss of system efficiency and an associated rise in operating costs. Maintenance is a time-consuming activity, but the payoffs can be significant. The following are areas that a poultry producer should be checking and maintaining to maximize efficiency and save on energy costs.

Dirty Fans and Shutters

Feather and litter dust becomes airborne easily and adheres to surfaces. The accumulation is higher where these materials are forced on or over objects. Any surface around the high air velocity of the ventilation fans will accumulate dust and dirt at an alarming rate. This is especially a problem for fan blades, shutters and safety screens. The accumulated dirt causes turbulence and restricts the openings, resulting in higher back-pressure for the fans. As a consequence, the overall efficiency of the fan system (CFM/Watt) drops dramatically. As individual fans become less efficient, they pull the same or more power but become less effective, moving less air. This, in turn, causes the controller to turn on more fans. During periods where partial loads are needed, more fans than necessary are running, Under full load conditions, the ventilation requirements may not be fully met, resulting in stress on the flock. Various studies estimate up to 40 percent loss in air flow with the first 1/8 inch of accumulated dirt on fan systems.

Fan Belt Wear and Tension

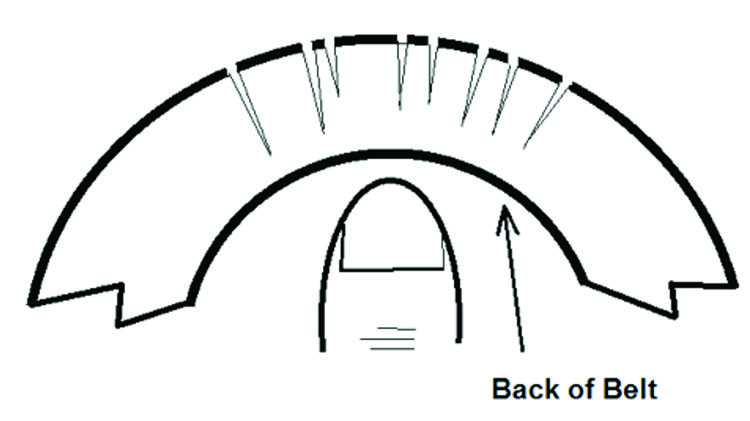

It might seem that a fan belt is either working properly or it isn’t, but there are actually multiple issues that can occur. The first problem might be the belt tension is not correct, resulting in belt slippage. This can also happen if the belt is old and the material has become hard. If there are visible cracks on the inside of the belt, it’s time to replace it (see Figure 1). Replace belts as needed to ensure good condition and correct tension with either an idler pulley or manually with a friction bolt. The belt tension setting is typically low (around 5 pounds pressure).

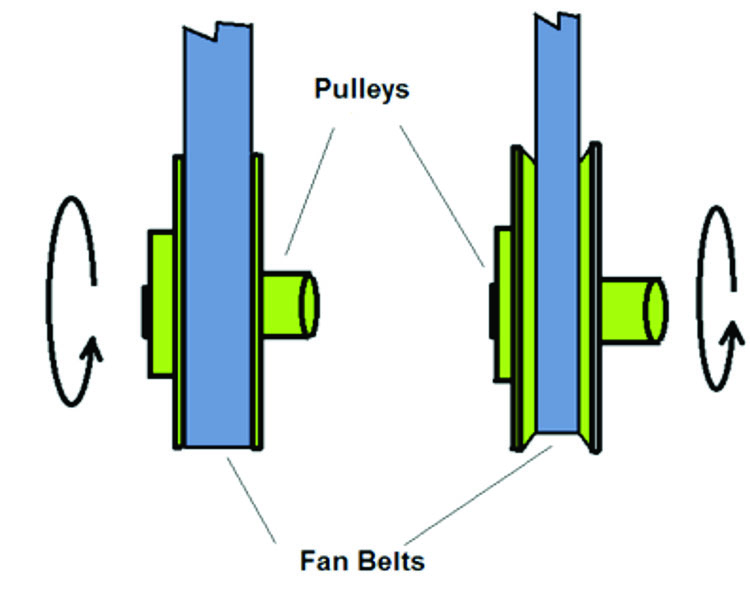

Another problem is caused when the belt sinks into the pulley (see Figure 2). This can result from the metal pulley notch widening with time, or the belt narrowing from wear. Either situation can effectively reduce the diameter of the pulley, causing the pulley and fan to run slower. This also causes the air flow to decrease and affects fan performance Additional fans may turn on to meet ventilation or temperature requirements. Studies estimate an average loss of 20 percent air flow capacity due to belt wear and tension.

Figure 1. Pressing on back of old belt reveals cracks.

Figure 2. Comparison of new pulley and belt (left) to worn pulley and belt (right).

Damaged Shrouds and Large Air Leaks

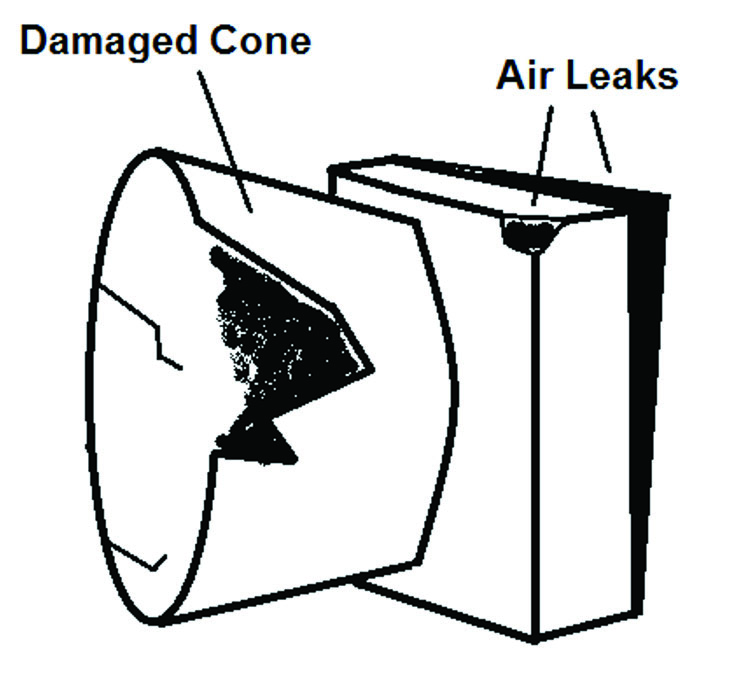

To be the most effective at moving air, fans must have special coverings that direct the air into and out of the fan. On the outlet sides of the fan, these devices use large cones or nozzles to increase the efficiency of the fan. These cones are attached to the poultry house via an air box that also covers the fan motor. Any damage to the outlet cones or airboxes reduces the effectiveness of the fan, especially where this results in large air leaks (see Figure 3). Another source of fan leakage is where the fan airbox is connected to the wall. Daylight showing through the connection of the fan unit to the wall inside the building is usually a very bad sign.

Figure 3. Damaged fan exhaust cone and multiple air leaks.

Loose Electrical Connections

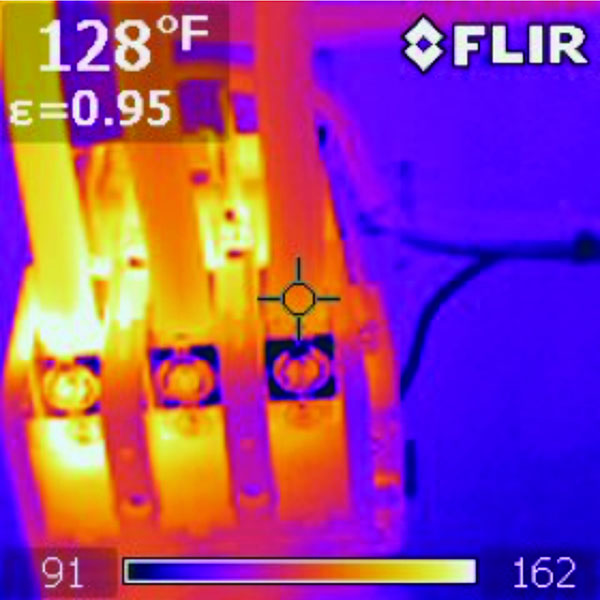

Loose electrical connectors will sometimes not let full current pass, which will lower the performance of fan motors. More fans may need to come on to satisfy ventilation requirements. In a three-phase motor system, a loose connection in a phase leg can burn out and ruin a motor fairly quickly (see Figure 4). Finally, loose electrical connections can heat up due to the higher resistance of the connection. This heating can cause even higher resistance—causing higher additional heating—increasing the risk of fire. Poultry house dust and construction in general is flammable and electrical fires could be catastrophic.

Figure 4. Infrared thermal photo of hot loose connection on three phase fuse box.

Summary

Producers pay for energy, so full utilization is beneficial. On a large poultry house, inefficiencies can cost hundreds or thousands of dollars per year. Keeping the poultry house fans and associated equipment in good shape and operating correctly is simply protecting a producer’s investment. As always feel free to contact Oklahoma Cooperative Extension Service at your local county office with any questions.

R. Scott Frazier, PhD, PE, CEM

Oklahoma State Energy Specialist