High Tunnels

High tunnels are unheated, plastic-covered hoop-house structures primarily used for growing vegetables, cut flowers or fruit brambles. High tunnels offer more protection for crops than the open field, and serve to extend the growing season for many popular crops such as leafy greens and tomatoes. While similar to greenhouses in many ways, there are a few key differences between the two types of structures.

- High tunnels rely on passive solar radiation for heat and natural ventilation for cooling needed for temperature control.

- Seeds or seedlings are normally planted directly into the soil or in raised beds within the tunnel.

- High tunnel frames are usually anchored directly into the ground instead of being anchored on a foundation such as a concrete pad.

High tunnels are very practical for farmers and commercial flower growers. Small high tunnels will also work for hobby growers on a backyard-size scale, but small-scale growers may also want to consider cold frames or unheated greenhouses.

Construction

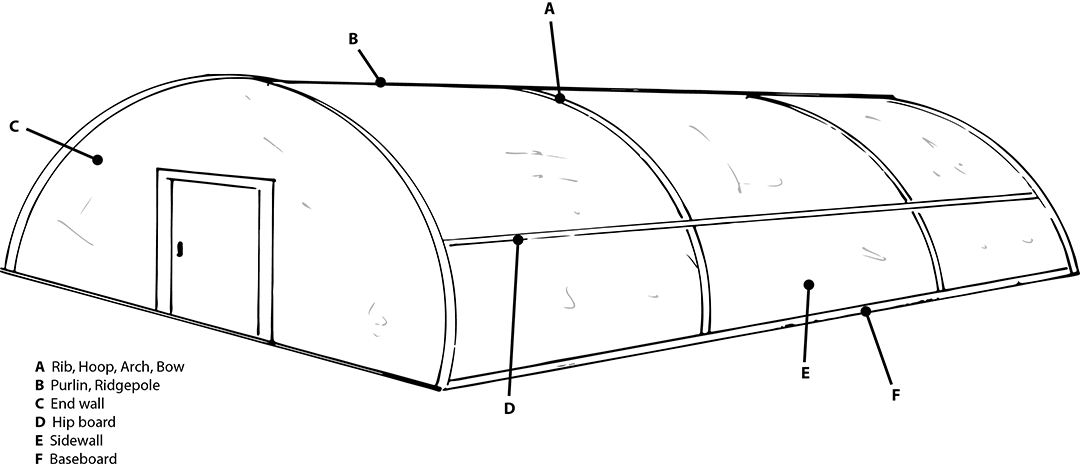

High tunnels can be either free-standing structures or gutter-connected with multiple bays. Aluminum or galvanized steel tubing are the most common framing materials because they are inexpensive, rust-resistant, long-lasting and the poles are sunk directly into the ground. Metal or wooden cross bars are attached horizontally along the sidewalls for reinforcement and stabilization (Figure 1). The most common covering material for a high tunnel is 6 mil polyethylene plastic (Figure 2). Single layer plastic is used the majority of the time because the single layer allows for ample light transmission through the plastic while still providing adequate heat retention. A double-layer of plastic has better heat retention, but lower light penetration. A shade cloth can be used to help control temperatures or solely as the covering material (Figure 3). Unlike greenhouses that remain covered all of the time, high tunnel plastic coverings may be applied and removed seasonally, depending on the requirements of the crop.

By definition, a high tunnel is tall enough for a person to comfortably walk upright inside, and tall enough to grow trellised crops such as tomatoes (Figure 4). This is to distinguish high tunnels from low tunnels, which operate in a similar fashion, but only stand 2 feet to 3 feet tall. While there are not standard dimensions for high tunnel size, they typically range from 14 feet x 30 feet up to 30 feet x 96 feet and can vary in design (Figure 5). Some growers elect to construct their high tunnels on skids so they can move the structure for crop rotational purposes.

Because high tunnels are lightweight structures that lack a solid foundation, the

poles must be well anchored in the soil. For non-movable high tunnels, the frame poles

should be sunk 2 feet to 3 feet into the ground to provide support during storms and

high winds (Figure 6). For movable high tunnels, anchor posts must be sunk, and the

structure attached to those. Even with these precautions, high tunnels can still be

damaged or even pulled up during high wind events.

Unlike greenhouses that can cost up to $20 per square foot, high tunnel costs can run as low as $0.50 per square foot for materials; construction labor costs are less prohibitive as well. Because they are non-permanent and less expensive to construct than greenhouses, high tunnels may provide more flexibility, especially for young farmers and growers with land shortages or those growing in urban settings.

The USDA’s Natural Resources Conservation Service (NRCS) established funding to encourage

season extension of high-value crops. NRCS funding is available through the 2014 EQIP

Seasonal High Tunnel Initiative. Stipulations for high tunnel funding states that

the structure must be at least 6 feet tall at its peak and covered in 6 mil greenhouse

film, must not be heated, and the grower must be willing to provide growing data and

have $1,000 in annual sales related to agriculture as well as the tax information

for those sales. If you have not previously sold produce, as long as you are able

to provide a detailed business plan as to how you are going to reach that $1,000 goal,

you should still be able to receive NRCS funding. Contact the local NRCS office for

additional information.

Locating the High Tunnel

High tunnel placement is one of the primary considerations in overall construction. An ideal site would be level or nearly level, well-drained with good soil and ideally would have a windbreak to moderate the prevailing wind. Prevailing winds are generally from the southwest in the summer and from the north in the winter, but specifics must be determined for each site by accessing Oklahoma climatology data (http://climate.ok.gov/index.php/climate). High tunnels placed perpendicular to prevailing winds typically receive the most damage.

In terms of light, the recommendation is to orient the high tunnel with the ridgeline

or roof peak running north to south below 400 latitude (400 latitude is the Kansas-Nebraska

state line). For gutter-connected high tunnels, ridgeline orientation should always

run north to south to prevent shading by the structures located to the south. This

will allow the entire high tunnel series to capture the most light. Regardless of

which direction you orient the high tunnel, the structure should receive at least

six hours of sunlight per day to promote best growth conditions.

Additionally, situate the high tunnel on ground that is slightly higher than the

surrounding land to help ensure that rain and snow runoff do not flood back into the

high tunnel and will drain away from the structure. Place the high tunnel away from

lone standing trees or small groups of trees to protect against damage from fallen

limbs. Also make certain there are not any trees or buildings blocking the high tunnel

from southern exposure. Because high tunnels rarely have supplemental lighting or

heating, ensuring ample exposure to sunlight is very important for successful crop

production.

Fertilization/Irrigation

One challenge for growing in a high tunnel is the limited options available for applying irrigation and fertilizer. Crops are grown directly in the soil, which makes slow-release fertilizers less practical than those applied as needed. Fertilizers mixed with water prior to application often are the most effective because they can be applied through a drip irrigation system or applied over the top of the crop using a hose-end sprayer.

The enclosed environment of a high tunnel means that no natural rainfall will take

place, so easy access to water is another consideration when placing a high tunnel.

Drip tape is the most common method of providing irrigation inside a high tunnel.

This method is both easy and relatively inexpensive to install, provides good irrigation

coverage of an entire area and helps limit the amount of water lost through evaporation.

Applying fertilizer through a drip irrigation system with an injector helps nutrients

penetrate the soil where plant roots have ready access and, by going directly into

the soil, prevents fertilizer damage on plant foliage (Figure 7).

While there are very few, if any, fertilizers designed specifically for use in a high tunnel, there are many options of both greenhouse and field fertilizers that work well in a high tunnel setting. Tailor specific fertilizer use on soil test recommendations and crop fertility requirements. This will provide the most efficient use of fertilizer and help maximize crop yields.

The enclosed environment of the high tunnel also means that excess irrigation can

easily build up high humidity levels, which can lead to disease and pest outbreaks.

Visual monitoring of the high tunnel is a good way to routinely check the irrigation

system. Take care of areas of standing water by redirecting drainage or correcting

irrigation systems. If standing water becomes a persistent problem, consider incorporating

organic matter or other soil amendments to help improve overall soil drainage.

Heating and Cooling

High tunnels are heated primarily through passive solar radiation. Over the course of the day, the sun’s rays heat the interior of the high tunnel, raising the temperature. This radiant heat also warms the soil in which the plants are being grown. As the sun sets, the collected heat inside the high tunnel serves to maintain a higher interior temperature than exterior, and the soil begins to release some of the stored heat collected during the day. Some growers, depending on their location and the crops being grown, also elect to use small space heaters to provide additional heat on cold nights. Row covers also are used on occasion to help hold in more of the stored warmth in the soil.

Cooling is achieved through increasing the interior airflow, allowing hot, humid

air to escape and cooler drier air to enter. High tunnels are constructed with sidewalls

that can be raised and lowered on both sides, allowing for ventilation along the entire

side of the structure. In warmer months, the sidewalls can be left open much of time

to allow for maximum air exchange. Early morning and late evening are common times

for the sidewalls to be raised or lowered for regulating temperatures. In some areas,

depending on the crops being grown, growers will remove the plastic coverings entirely

during the summer months, reinstalling them as the weather turns colder in the fall.

Integrated Pest Management

With the open plan of a high tunnel, pests (both insects and diseases) are inevitable. As with a greenhouse crop or a field crop, the best defense against a pest infestation is constant monitoring and daily scouting for new problems and outbreaks. The open sidewalls of a high tunnel can both help and hinder efforts to control pest outbreaks. The outside access allows new pests to enter the high tunnel, but also allows pest predators access, which often results in the natural balance between pest and predator being maintained with little input by the grower.

Due to their enclosed design, high tunnels quickly become hot and humid environments,

especially during the warmer summer months. These environments, in turn, become breeding

grounds for diseases such as leaf mold, powdery mildew and root rot complexes. Fortunately,

along with applied treatments for these diseases, there are simple changes in cultural

practices that can help control outbreaks. High tunnels lack the interior fans and

cooling walls found in greenhouses, so other cooling methods are used. Maintaining

adequate airflow through raising the sidewalls on hot days to allow warm inside air

to escape is the best and easiest way to keep down risk of disease. Other steps to

take include:

- Selecting disease-resistant plant varieties that are suited to your climate.

- Practicing crop rotation to prevent soil-borne diseases from starting.

- Not overwatering or fertilizing because excess water or nutrients promote the growth of bacteria and fungi and the spread of disease.

- Good sanitation with the prompt removal of diseased or dead plant material.

Biological controls often work well in a high tunnel, especially during warmer months when the sidewalls are open to facilitate the movement of natural enemies into the infested area. Keep in mind that most natural enemies of plant pests attack only during one or two life stages, so timing the release of pest predators is important. Also, some predators, such as ladybeetles, while effective, will move elsewhere once the pest population has dropped too low to support them. In a greenhouse, this might not be an issue, but with a high tunnel, this means the ladybeetles will simply fly away once their food source diminishes. This can be partially controlled by selecting predator species that are less mobile, such as predatory nematodes, or by selecting predators such as the minute pirate bug that feed on a wide range of pests.

Release timing and selection of the natural enemy are the two most crucial factors

in the successful use of natural predators. Even the most effective predator will

be useless against a pest outbreak if it is not targeted towards that pest. For very

small pest outbreaks, controls such as sticky traps are likely to be most effective

because there might not be a large enough pest population to support a predator population.

On the other hand, a large and intense pest outbreak can easily overwhelm a predator

population, and so the judicious application of a compatible pesticide (a pesticide

that will not harm the biological control species) might also be necessary to allow

the predators to gain the upper hand. If the application of a compatible pesticide

is required, ensure there is no pesticide residue in the area prior to the release

of the natural enemies. Many predators have at least some tolerance to some pesticides,

and there are many programs and applications to help determine which pesticides will

work in concert with which biological controls.

One other consideration when using natural enemies to fight pest outbreaks in a high

tunnel is the temperature sensitivity levels of both pests and pest predators. Unlike

a greenhouse, which is kept at a consistent temperature even in cold weather, a high

tunnel’s internal temperature and humidity levels can easily drop below the tolerance

threshold of predators, especially during the winter months. For pest outbreaks during

this time, there is likely to be heavier reliance on scouting and use of sticky traps

and pesticides.

As with greenhouse integrated pest management, keeping the high tunnel clean and

free of dead or diseased material helps prevent the spread of disease, while quarantining

new plant material helps limit the introduction of new diseases and pests into the

environment. Remember that a high tunnel is more exposed to the outside world than

a greenhouse and this allows for free movement of both pests and natural enemies in

and out of the high tunnel.

Growing Crops in a High Tunnel

Vegetable Crops

High tunnel use for vegetable crop production falls into two main categories:

- growing warm-season crops under cover to protect against cold temperatures and extending the growing season into fall and early spring, and

- growing cool-season crops under cover during the coldest months to extend that season.

Warm-season crops such as tomatoes are almost exclusively grown in high tunnels in certain parts of the country (Figure 8). In New England, farmers have been using high tunnels for tomato production for more than a decade. Unpredictable summer weather and wind-transferred fungal diseases were the primary drivers behind this practice. High tunnels allow tomatoes to be staked or trellised, which can help increase tomato production and limit waste from soil related fruit diseases. Trellising also makes monitoring for pests and diseases easier, facilitates harvest and reduces potential damage to plants.

High tunnels also provide protection against hail, wind and strong summer thunderstorms, all of which can damage or destroy vegetable crops. For crops that are heavy feeders, a mobile high tunnel can be used for the season, then removed to allow the field to stand fallow or for additional fertilizer, compost and other soil amendments to be tilled in. Additionally, movable high tunnels may be used to protect delicate crops leading up to harvest, protect from pests such as birds, or both to help ensure a quality crop.

Cool-season crops, such as leafy greens, peas and radishes, can be grown in high

tunnels throughout the winter, even in northern states. Species selection is important

for deciding what to grow as temperature tolerance levels change dramatically across

species. Due to lower sunlight levels and cooler temperatures during the winter months,

plant growth is slowed down, but several fall-planted crops can be ready for harvest

in late fall and can be multi-harvested during winter months. Cool-season crops that

overwinter will be ready for harvest in the late winter/early spring prior to spring-planted

crops being planted. For small and medium-sized growers, allowing a vegetable crop

such as spinach to overwinter is economically feasible. Early spring greens can be

sold at farmer’s markets and through CSA’s (community supported agriculture).

Cut Flowers

High tunnels are a popular option for commercial cut flower growers. These structures are relatively inexpensive to construct and maintain as well as allow for earlier harvests in the spring and later into the fall. Additionally, growing in a high tunnel provides several significant benefits to cut flower growers. Soil temperatures remain higher inside the high tunnel, even in colder months, which allows growers to start plants earlier in the spring, and grow others later into the fall. Some growers will also place row covers over temperature-sensitive crops, even inside the high tunnel, which provides an extra temperature buffer zone.

As discussed in the fertilization/irrigation section, crops in high tunnels are planted

directly into the soil or, on occasion, into soil-filled raised beds. This allows

for greater ease of movement through and around a cut flower crop, which aids in scouting

for pests and applying pest treatments.

Growing cut flowers in a high tunnel provides market advantages as well. For most

plant varieties, cooler nighttime temperatures induce stem elongation, especially

when paired with warmer daytime temperatures, a desirable characteristic for cut flowers.

Additionally, common cut flowers such as anemones, delphiniums and larkspur either prefer cooler temperatures for flower initiation, or can be forced to earlier flowering by cooler temperatures. This allows growers to move their product through to a marketable stage earlier than with field production, and with lower heating/cooling costs than greenhouse production. High tunnels also increase the local zone hardiness level by two to three zones (i.e. from hardiness zone 6a outside to 7b inside a high tunnel). The use of row covers inside the high tunnel during the coldest months can increase one more hardiness zone. This allows growers to expand the species of flowers grown for niche markets and superior quality crops.

Fruits

While many varieties of vegetables are suitable for growing in a high tunnel, the same is not true for varieties of fruiting plants. Fruiting groups well-suited to high tunnel growing include strawberries and fruiting brambles, such as blackberries and raspberries. Use of high tunnels can greatly extend the production season, especially in more northern parts of the country. Strawberries will start producing as early as May and extend through late November when grown in high tunnels. This provides economic advantages for small berry growers as early and late season berries capture premium prices.

Another advantage of growing berries in high tunnels is crop consistency and quality.

Raspberries and blackberries are both prone to sunburn and windburn, which discolors

the berries and results either in an unsellable product or one that sells at a reduced

price. High tunnels offer protection from sun and wind intensity, as well as protecting

against late spring and early fall frosts that would otherwise force an end to berry

production. Finally, high tunnel production of berries requires less management for

insect and wildlife pests to prevent crop loss from birds and other animals.

Additional High Tunnel Resources

High Tunnel Leafy Greens, Oklahoma State University

Supply Companies

American Plant Products and Services

9200 N.W. 10th

Oklahoma City, OK 73127-9722

Growers Supply

1440 Field of Dreams Road

Dyersville, IA 52040