Hay Feeder Design Effect on Hay Waste

- Jump To:

- Introduction

- Literature

- Discussion

Introduction

In a Center for Farm Financial Management (CFFM) report, total feed costs excluding pasture averaged $426 per cow on 152 ranching operations. Similarly, in a study on 81 Kansas ranching enterprises, feed costs per cow (excluding pasture cost) averaged $343 per head (Pendell and Herbel, 2021). In the same Kansas study, the most profitable 1/3 of operations had $145 per cow lower feed costs compared to the least profitable 1/3 of operations. Clearly, feed costs represent a major portion of annual costs in a beef cow/calf enterprise. In the CFFM data, harvested forage accounted for 65% of the non-pasture feed costs. While variable, most Oklahoma cow/calf enterprises stock their pastures with the intent to provide adequate grazed forage for nine to 10 months each year, then feed hay for the remaining two to three winter months.Othersmaysupplementhigherqualityhaythroughout the winter to stretch standing forage availability and to provide supplemental protein and energy.

Hay waste is a significant contributor to annual feed costs and yields no return unless the residue is distributed throughout the pasture or hay meadow. For example, in one experiment, feeding hay without a hay feeder resulted in 45% hay waste (Bell and Martz, 1973). For this reason, the use of hay feeders is a common practice in most beef cattle operations. An important factor often overlooked is the impact that hay feeder design has on waste accumulation and thus, winter feed costs. In this fact sheet, studies are reviewed and summarized describing the effects of feeder design on hay waste.

Literature

Materials and Methods—Biskirk et al., 2003

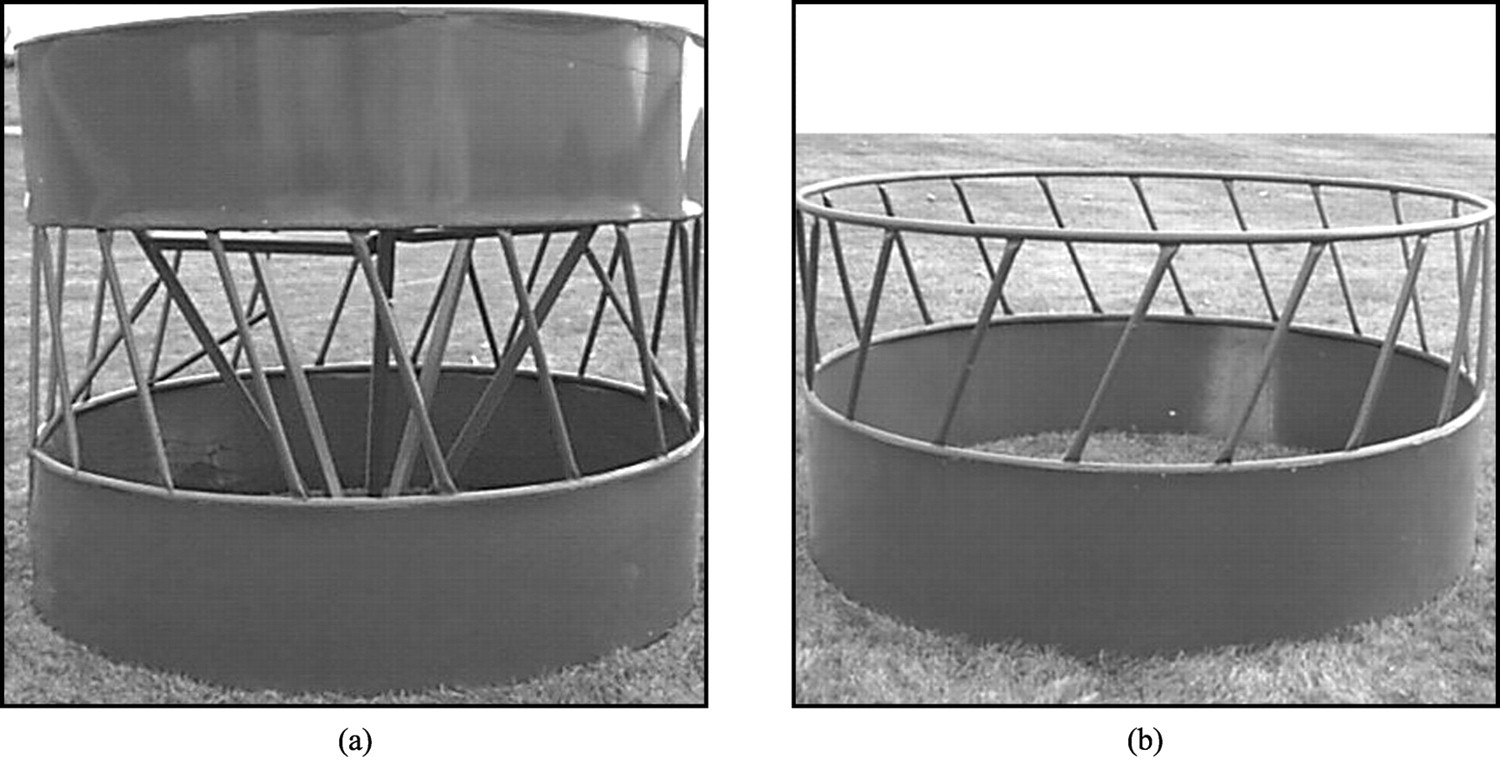

In the first experiment (Buskirk et al., 2003), 80 non -lactating, pregnant beef cows were used to determine the effect of hay feeder design on hay waste. Cows were divided equally into two weight blocks and within each weight block they were divided into two treatment groups of 20 cows each. Within a weight block, one group of cows was housed in a pen containing the sheeted bottom feeder design with a basket insert (basket, sheeted), shown in Figure 1, and one group of cows was housed in a pen containing the sheeted bottom feeder design (sheeted) without the added cone feature, also shown in Figure 1. Thus, their experiment included two pen replicates for each feeder type. Both feeder types provided 14.6 in. of linear feeder space per cow and 18 feeding spaces. The top rail for the basket, sheeted feeder was 75.2 inches above the pen surface, while the top rail of the sheeted feeder was 47.6 inches above the pen surface. Each bale of hay fed was weighed before being placed in the pen. Alfalfa hay was fed during the first seven-day period and orchardgrass hay was fed during the latter seven-day period. Hay that fell on the concrete surrounding each feeder was considered waste and was collected and weighed daily. Feed disappearance was calculated as the amount of hay delivered to each pen, minus the residual amount of hay remaining in the feeder at the end of a seven-day period. The total amount of hay re covered from the concrete pad around the perimeter of each feeder was considered feed waste. Percentage waste was calculated as the amount of waste divided by feed disappear ance. Feed intake was estimated as the difference between feed disappearance and feed waste.

Results

Hay waste was low in this experiment for both feeder styles. However, the basket sheeted feeder design resulted in the least hay waste at 2.84% of original bale weight. The sheetedbottom feeder designwithout theadded basket feature resulted in a greater amount of hay waste at 4.97% of original bale weight (Table 1). It was speculated that limited access to the top of the bale also resulted in reduced waste for the basket, sheeted design. Cows could pull hay from above the sheeted feeder top rail early during the feeding period.

Figure 1. Round bale feeders used in Experiment 1 (Buskirk et. al 2003): (a) basket, sheeted; (b) sheeted.

| FEEDER DESIGN | FEEDER DESIGN | |

|---|---|---|

| ITEM | Basket (Sheeted) | Sheeted |

| initial cow weight, lbs | 1386 | 1392 |

| Initial cow BCS | 5.8 | 5.9 |

| Daily hay disappearance, lbs/cowa | 26.5 | 26.7 |

| Hay waste, % of hay disappearancea | 3.5a | 6.1b |

| Daily hay waste, lbs/cowa | 0.9b | 1.5c |

| Hay intake, % of cow body weighta | 1.8 | 1.8 |

|

a Dry matter basis b, c Means within a column are different, P<0.05 |

||

Table 1. Effect of feeder type on hay waste and intake by beef cows; Buskirk et. al 2003.

Materials and Methods—Moore and Sexten, 2015

In the second experiment (Moore and Sexten, 2015), 48 gestating crossbred cows were used to determine the effect of hay feeder design on hay waste. Three feeder de signs and two forage types were used. The feeder designs (Figure 2) included open ring with slanted feeding stations (open), sheeted lower section with slanted feeding stations and tapered sides (tapered, sheeted) and sheeted lower and upper sections with straight feeding stations and a chain cone (chain, sheeted). The two forages fed were alfalfa haylage (DM: 41.0 %, CP: 17.0 %, NDF: 49.4 %) and tall fescue hay (DM: 92.0 %, CP: 7.5 %, NDF: 66.6 %). Six combinations were applied to six pens in each of six 12 day periods. All cows were supplemented with 2.2 lbs. per head per day of feed containing 42% dried distillers grains with solubles, 24.7% wheat middlings, 24.4% ground corn and 8.9% mineral and vitamin premix. At the beginning of each treatment period, cows were acclimated to the forage and feeder for 12 days. Waste and orts were cleared after the acclimation period and a new bale was placed to begin data collection. Waste was collected, weighed and sampled at 24, 48, 72 and 96 hours following new fescue hay bale introduction, alfalfa haylage waste at 24, 48 and 72 hours following bale introduction due to less DM per bale. Orts were weighed and sampled at 96 hours for fescue hay and 72 hours for alfalfa haylage. Waste was defined as forage outside the feeder at collection and orts as forage that remained in the feeder at the end of the period.

Results

Alfalfa haylage waste was lower compared to fescue hay and waste was not different among feeder designs (5-7%). When dry fescue hay was fed, the open feeder design resulted in the greatest amount of hay waste at 19.2% of original bale weight. The tapered, sheeted feeder design resulted in less waste than the open feeder at 13.6% of original bale weight. The chain, sheeted design resulted in the lowest hay waste at 8.9% of original bale weight (Table 2).

| Image | Caption |

|---|---|

|

a) open |

|

b) tapered, sheeted |

|

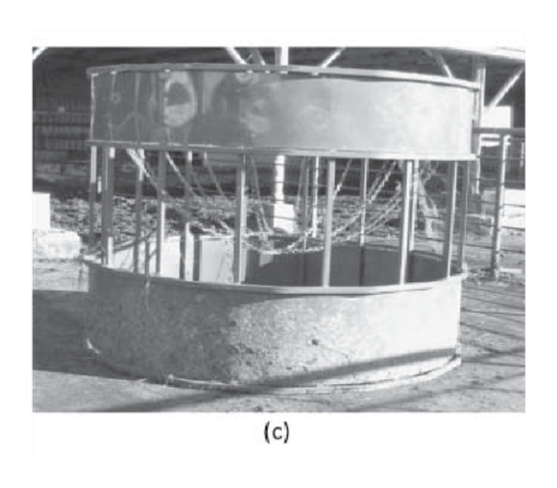

c) chain, sheeted |

Figure 2. Round bale feeders used in Experiment 2 (Moore and Sexton 2015): a) open; b) tapered, sheeted; c) chain, sheeted.

Forage and Feeder Treatment

| ALFALFA | ALFALFA | ALFALFA | TALL FESCUE | TALL FESCUE | TALL FESCUE | P-VALUE | P-VALUE | P-VALUE | |

|---|---|---|---|---|---|---|---|---|---|

| Chain (Sheeted) | Tapered (Sheeted) | Open | Chain (Sheeted) | Tapered (Sheeted) | Open | Forage | Feeder | Forage x Feeder | |

| # of Bales | 12 | 12 | 12 | 12 | 12 | 12 | |||

| Bale Wt., (lbs) | 806.9 | 778.2 | 822.3 | 1221 | 1219 | 1193 | <0.01 | 0.90 | 0.61 |

| Waste, (% of bale weight) | 6.5cd | 4.9d | 7.0cd | 8.9c | 13.6b | 19.2a | <0.01 | <0.01 | <0.01 |

| DMI, % of Cow BW | 2.32 | 2.18 | 2.30 | 2.21 | 2.20 | 2.50 | 0.24 | 0.63 | 0.52 |

| a-d Within a row, means without common superscripts differ, P< 0.05 | |||||||||

Table 2. Effect of forage type and bale feeder on hay waste, orts and disappearance; Moore and Sexten, 2015.

Materials and Methods—Sexten et al., 2021

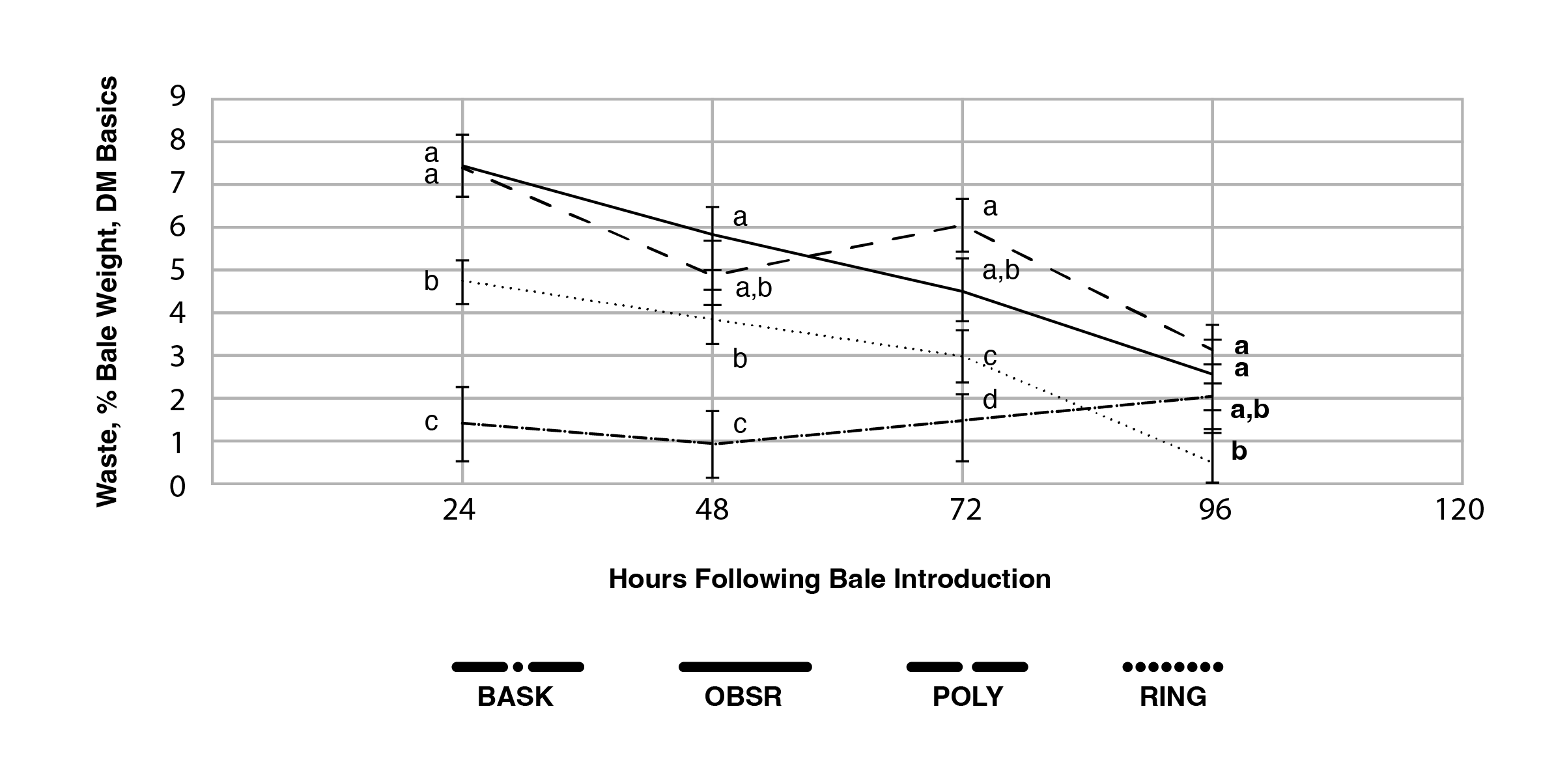

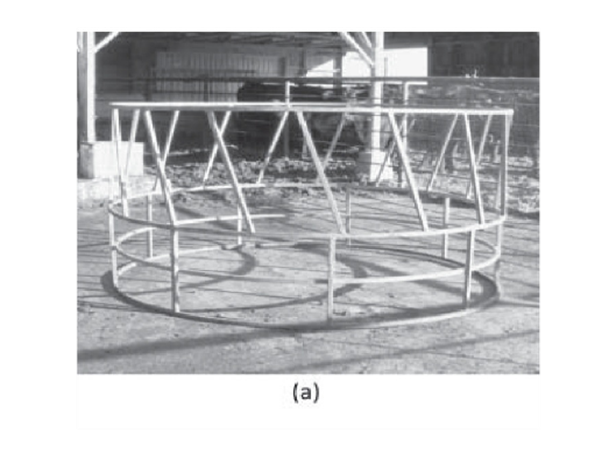

In experiment 3, Sexten et al., 2021 used 56 Angus and Angus x Hereford crossbred cows in the second trimester of pregnancy. Fourteen cows were allotted to one of four five-acre paddocks to test four feeder designs for four experimental periods. The designs used, as shown in Figure 3, were open-bottom steel ring (open steel), polyethylene pipe open-bottom ring (open poly), sheeted-bottom steel ring (sheeted) and sheeted-bottom ring with a basket feature (basket, sheeted).

Three bales of hay were fed during each period. The first bale was used to familiarize the cows with the feeder design. The second and third bales fed during each period were used to determine the amount of hay waste for each of the feeder designs. Bales were weighed on an electronic scale prior to feeding. Hay waste was collected every 24 hours for four consecutive days for each bale. Waste was defined as any hay on the concrete or pen surface outside of the feeder perimeter. When about 80% of the bale had been consumed by the cows, hay remaining within the feeder was weighed on an electronic scale, the concrete pad was cleared and the next pre-weighed experimental bale was placed within the feeder, initiating the next period.

Results

The two open steel and open poly feeders resulted in similar hay waste averaging 20.4% of original bale weight (Table 3). The sheeted bottom design resulted in less hay waste at 12.4% of original bale weight (Table 3). The added features in the sheeted bottom, basket design resulted in the least hay waste at 5.5% of original bale weight (Table 3). In addition to reduced hay waste attributed to the basket mechanism and the sheeted bottom, limited access to the top of the bale likely also contributed to minimal hay waste with this feeder design. With lower waste, more hay remained in the feeder at the end of each 96-hour feeding period (orts).

With the exception of the basket, sheeted design, hay waste was found to be greatest during the first 24 hours after a new bale was placed in the feeder and gradually declined thereafter. However, 24-hour waste increased slightly for the basket, sheeted feeder once the bale had dropped below the basket mechanism (hours 72 and 96). Increased waste later during a feeding period appeared to be due to the hay becoming more evenly distributed throughout the base of the feeder and thus more readily available at the feeder’s perimeter where it could be dragged out and dropped on the pen surface (Figure 4).

| Image | Caption |

|---|---|

|

a = open |

|

b = open |

|

c = sheeted |

|

d = basket, sheeted |

Figure 3. Round bale feeders used in Sexten et. al 2021: a = open; b = open, poly; c = sheeted; d = basket, sheeted.

Feder Design

| ITEM and (Design) | STEEL (Open) | POLY (Open) | SHEETED | BASKET (Sheeted) | P-VALUE |

|---|---|---|---|---|---|

| # Bales Measured | 8 | 8 | 8 | 8 | |

| Bale DM wt., lbs. | 1369 | 1400 | 1349 | 1329/ | 0.15 |

| Total waste, % of bale DMa | 19.7a | 21.1a | 12.4b | 5.5c | <0.01 |

| Orts, % of bale DMb | 6.49a | 4.62a | 7.18a | 26.6b | <0.01 |

| a Total hay waste through 96 hours after bale introduction, expressed as percent

of initial bale DM weight. b Orts=hay DM remaining inside the feeder 96 hours after bale introduction to the paddock. a-d Within a row means without a common superscript differ (P< 0.05). |

|||||

Table 3. Effect of hay feeder design on hay waste, Sexten et al., 2021

Figure 4. Hay waste, expressed as a percent of original bale weight, by hours after bale introduction to the pen. BASK = feeder with sheeted bottom and a basket feature; OBSR = conventional open bottom steel ring feeder; POLY = polyethylene pipe open bottom ring feeder; RING = sheeted bottom steel ring feeder. Feeder × day interaction, P < 0.01. Within day, means without a common superscript differ (P < 0.05).

Materials and Methods—Sexten et al., 2021

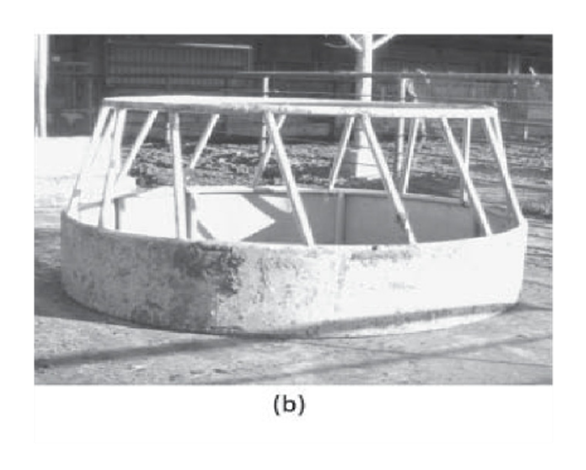

In the fourth experiment, Sexten et al. (2021) used 64 Angus and Angus x Hereford crossbred cows in their third trimester of pregnancy. Sixteen cows were allotted to one of four five-acre paddocks to test two feeder designs for four experimental periods. The designs used, as shown in Figure 4, were the same sheeted design feeder used in Experiment 3 and the same sheeted feeder with a steel basket insert (basket, sheeted). Waste measurement procedures were identical to those described for Experiment 3.

Results

The sheeted bottom feeder design resulted in the most waste at 7.7% of original bale weight during the first 24 hours. The basket, sheeted feeder design resulted in only 2.14% of original bale weight during the first 24 hours. The two feeder designs did not differ significantly in hay waste during the second 24-hour period. The total waste during the entire 48 hours. of the experimental periods was greatest with the sheeted design 11.9% of the original bale weight, while total waste was 4.77% of original bale weight in the basket, sheeted design (Table 4).

| Image | Caption |

|---|---|

|

Round bale feeder sheeted |

|

Round bale feeder basket, sheeted |

Figure 4. Round bale feeders used in Experiment 2 of Sexten et. al 2021: Top = sheeted; bottom = basket, sheeted.

Feeder Design

| ITEM | RING | CONE | P-VALUE |

|---|---|---|---|

| # Bales measureda | 8 | 8 | |

| Bale DM wt., lbs. | 1179 | 1183 | 0.89 |

| 1st 24h waste, % of bale DMb | 7.70 | 2.14 | <0.01 |

| 2nd 24h waste, % of bale DMb | 4.16 | 2.62 | 0.11 |

| Total 48h waste, % of bale DMb | 11.9 | 4.77 | <0.01 |

| Orts, % of bale DMc | 24.6 | 29.40 | 0.16 |

| Forage DM consumed, % of bale DM | 63.6 | 65.9 | 0.25 |

|

a Hay waste measured for two bales during each period over four periods b Hay waste expressed as a percentage of initial bale weight for first 24 hours, second 24 hours and total 48 hours. c Orts= hay DM remaining inside the feeder for 48 hours after bale introduction to the paddock. |

|||

Table 4. Effect of hay feeder design on hay waste, Sexten et al., 2021

Discussion

Open-style feeders are popular throughout the livestock industry because they are inexpensive, light weight and therefore, relatively easy to move. However, substantial waste is created when open-style feeders are used (19 to 21%). Waste may contribute to organic matter, nitrogen, phosphorus and other soil nutrients and therefore may not always represent a total loss. However, an intentional management or feeding strategy must be employed to distribute the waste throughout the pasture for the nutrients to be effectively utilized.

According to these experiments, a sheeted bottom may preserve around 5%–8% of the hay crop due to reduced hay waste. Therefore, incorporating some type of solid sheet around the bottom of round-bale feeders is an effective and relatively inexpensive way to reduce hay feeding waste.A steel sheeted bottom will add some expense and approximately 30 pounds to the weight of the feeder.

In all four of the experiments reviewed, a modified cone or basket feature, in combination with a sheeted bottom and restricted access to the top of the bale resulted in substantial hay savings. A modified cone or basket feature prevents the animal from getting direct access to the bale and creates a feeding space in the bottom sheeted portion of the feeder. This design allows the animal to retrieve forage from the cone/bas-ket, while the feeding space catches hay that would otherwise fall out onto the pen surface and be wasted. Adrawback to this design is the increased weight when compared to basic open steel or polyethylene hay feeders, necessitating the use of heavy equipment in order to move them. Feeders with added features of sheeted bottom, top and a basket mechanism will cost substantially more than open-design feeders.

Finally, in two experiments when a basket insert was used in conjunction with a sheeted bottom feeder, hay waste was dramatically reduced. While this feeder design adds some flexibility (use or don’t use the basket insert), the design is heavy and requires a front-end loader or hydraulic bale bed to move. Obviously, a tractor and front-end loader will be required to place hay in the basket insert.

A final consideration related to feeder design is access to hay by lighter cattle. The different basket mechanisms are essentially designed to hold the bale together longer in the center of the feeder. Once the hay closer to the feeder perimeter has been consumed by the calves, they may not be able to reach the hay in the center.

An example of potential savings due to hay feeder design is necessary to provide context to the findings above. According to data from experiment 3 (or three?), the value of waste per 1,000 lb. bale of native grass hay priced at $70/ bale is about $14 using the open steel or open poly feeder designs. Using the sheeted bottom design would result in $8.68 waste value per bale. Using the basket, sheeted design would reduce hay waste value to about $3.85 per bale. If 200 bales are fed to a cow herd through a winter feeding period, annual hay waste value would be about $2,800, $1,736, and $770, respectively.Hay feeder designs that restrict access to hay near the feeder perimeter and provide feeding space inside the feeder substantially reduce hay waste. Using feeders with a sheeted bottom, a sheeted top (or other mechanism to restrict access to the top of a new bale) and (or) a basket feature can reduce the amount of hay required to winter beef cows. Thus, a more efficient hay feeder design reduces winter feeding costs.

Resources Cited

Comerford, J. W., Buckmaster, D. R., & Cash, E. H. (1994). Effects of three storage methods on nutrient losses from harvest, storage and feeding of large bales. J. Anim. Sci, 72(Suppl 2), 130.

Pendell, D. L., & Herbel, K. L. (2021). Differences Between High-,Medium-,and Low-ProfitCow-CalfProducers:An Analysis of 2015-2019 Kansas Farm ManagementAssociation Cow-Calf Enterprise. Kansas State University Department Of Agricultural Economics Extension Publication.

Sexten, A. J., McMurphy, C. P., Mourer, G. L., Brown, M. A., Richards, C. J., & Lalman, D. L. (2011). Effects of bale feeder type and supplementation of monensin on hay waste, intake, and performance of beef cattle. THE EFFECTS OF HAY PROCESSING AND FEEDER DESIGN ON HAY UTILIZATION, 41.