Formulating Swine Rations

- Jump To:

- Calculating Rations

Feed costs represent 55 to 70 % of the cost of producing hogs. Therefore, close attention to nutrition should carry a very high priority. This includes formulation of swine rations utilizing the most accurate information available. The major goal of a nutritionist or a pork producer in a swine feeding program should be to supply at a feasible cost the nutrients needed at the right time in the animal’s life. The feed ingredients needed can be divided into five general groups. A discussion of these groups follows. For additional information on feed ingredients, refer to Extension Fact Sheet 3500, “Swine Nutrition,” or 3502, “Feed stuff Composition for Swine Rations.”

Energy — Carbohydrates of cereal grains such as corn, sorghum grain, wheat and barley supply

most of the energy in swine rations. Energy may also come from fats, oils, and protein.

Energy is usually expressed as Digestible Energy (DE) or Metabolizable Energy (ME).

Metabolizable Energy is defined as the gross or total energy of the feed minus the

energy lost in the feces and urine. Digestible Energy is the gross energy of the feed

intake minus the energy lost in the feces. It does not take into account energy lost

in urine. ME values are approximately 96% of DE values for mixed feeds; however, individual

feed ingredients will vary considerably from this value.

When expressed as DE, it is desirable for growing finishing rations to contain 1,500

kilocalories (kcal) per pound. When expressed as ME, a corresponding value would be approximately 1,440 kcal.

Protein— Part of the protein in a swine ration will come from cereal grains. However, the

protein of cereal grains is of rather poor quality for swine as a result of the low

content of certain essential amino acids such as Lysine, threonine, tryptophan, and

methionine. This necessitates the addition of a high quality protein supplement such

as soybean meal, peanut meal, milk byproducts, meat and bone meal, or others.

However, meat and bone meal or tankage contain high levels of calcium and phosphorus,

which can result in too high mineral content in a swine ration if excessive amounts

are fed. Soybean meal, which is readily available in Oklahoma, is usually the most

feasible supplement to use for swine rations.

Minerals—Most swine rations need supplemental sources of minerals. Cereal grains are especially

low in calcium and are only a fair source of phosphorus, since much of the phosphorus

in cereal grains is unavailable to the pig.

Swine rations based largely on cereal grains and soybean meal need supplementation

of both of these minerals. Several commercial products available on the market to

supply supplemental calcium and/or phosphorus are listed in Table 1.

Table 1. Common Calcium and Phosphorus Sources*

| Ingredient | % Calcium | % Phosphorus |

|---|---|---|

| Dicalcium Phosphate | 20-24 | 18.5 |

| Calcium carbonate | 38 | - |

| Dicalcium-Monocalcium Phosphate | 15-18 | 21 |

| Deflourinated rock phosphate | 32 | 18 |

| Sodium tri-poly phosphate | - | 25 |

| Bone mean, steamed | 24 | 12 |

Other minerals needed in most swine rations include sodium, chlorine, copper, iron, iodine, zinc, manganese and selenium. Sodium and chlorine are supplied by salt. Trace mineral mixes, trace mineralized salt or combination trace mineral-vitamin premixes are normally used to supply trace minerals. Supplying trace minerals through combination trace mineral-vitamin premixes is the most popular method in Oklahoma.

If a combination trace mineral-vitamin premix is the method used, the following ingredients

level using 5 pounds per ton will be adequate:

Zinc 4.0%

Iron 3.2 %

Copper .4 %

Iodine .008 %

Manganese .8 %

Selenium .004 %

Vitamins — Vitamin A, Vitamin D, Vitamin E, Vitamin K, riboflavin, niacin pantothenic acid, choline, and Vitamin B12 are the vitamins that normally need to be supplemented to a swine ration. Vitamin premixes or combination trace mineral-vitamin commercial premixes can be purchased to supply these vitamins.

A vitamin premix supplying the following amounts of ingredients per pound and using

5 pounds per ton will be more than adequate in these vitamins when using feed grains

such as corn, sorghum grain, barley, wheat, or oats in combination with soybean meal.

Vitamin A 800,000 I.U.

Vitamin D 80,000 I.U.

Vitamin E 3,000 I.U.

Vitamin K 660 mg.

Riboflavin 1,000 mg.

Pantothenic Acid 4,500 mg.

Niacin 7,000 mg.

Choline Chloride 20,000 mg.

Vitamin B12 5 mg.

Antibiotics — Antibiotics and other feed additives are commonly included in swine rations as an aid in increasing growth rate, improving feed efficiency and controlling many diseases. Usually the higher the disease incidence in a swine herd, the greater the response will be to antibiotics in the ration. Greatest growth response to antibiotics generally occurs with younger pigs up to 120 pounds.

Some antibiotics or chemotherapeutics and all arsenic and sulfa compounds are required

by Federal Law to be withdrawn from finishing rations within a specified time prior

to slaughter. Always read the label and comply with the withdrawal time. It is the

livestock producer’s responsibility to comply with withdrawal periods.

Alfalfa Meal — Alfalfa meal is sometimes used in swine rations. One reason for using alfalfa meal

is to supply essential vitamins. However, when using a good fortified vitamin premix,

it is not essential to use alfalfa meal in swine rations. There are, however, pork

producers who like to use small amounts of alfalfa meal in swine rations as safeguards

for supplying vitamins.

Calculating Rations

Many swine producers will use rations calculated by others. Sources of available formulas are listed at the end of this fact sheet. Some producers will use the trial and error method of calculating rations with the use of simple electronic calculators. A few producers who have access to computers may elect this method of calculating rations. Computers may be used to calculate linear programmed least cost rations. The method described in this fact sheet is the “Square Method.” It is a simple easy method for producers who wish to calculate their own rations but do not feel they need the additional information on amino acid content that computer formulated rations usually furnish.

Formulating the Ration

Before a person can formulate a swine ration, there are a few facts that must be known:

- What are the recommended nutritional levels for pigs at various weights or ages? Recommended nutritional levels are given in Table 2.

- What is contained in the feeds that are used. The Metabolizable Energy, protein, calcium, and phosphorus of common feedstuffs are given in Table 3. Additional information on other nutrients or ingredients not listed can be obtained from Extension Fact Sheet F-3502, “Feedstuff Composition for Swine Rations.”

Table 2. Suggested Nutrient Levels

| To 40 lb. | 40 to 125 lb. | 125 lb. to mkt. | Brood Sows | |

|---|---|---|---|---|

|

Protein % in ration lb. per ton |

18.0 360 |

16.0 320 |

14.0 280 |

14.0 280 |

|

Protein % in ration lb. per ton |

.75 15 |

.65 13 |

.60 12 |

.85 17 |

|

Phosphorus % in ration lb. per ton |

.65 13 |

.55 11 |

.50 10 |

.65 12 |

|

Salt % in ration lb. per ton |

.5 10 |

.5 10 |

.5 10 |

.5 10 |

Formulation Procedure — In formulating rations there is a fixed portion of the ration and a variable portion.

The fixed portion may include the following ingredients and range in amounts as illustrated:

% In Ration

Alfalfa Meal 2-5-10.0

Salt 0.3-0.5

Vitamin—Trace Mineral Premix (as directed)

Dicalcium Phosphate 0.5-2.0

Calcium Carbonate 0.5-1.0

The variable portion of the ration will include the grain and protein source.

The following example will be for balancing a 14 % crude protein finishing swine

ration. It will be a one ton (2000 lb) mix using sorghum grain and soybean meal as

the basic ingredients for energy and protein.

As a fixed portion of the ration the following is selected:

Ingredient % In Ration Lbs/Ton

Alfalfa Meal 5.00% 100

Salt 0.50 % 10

Vitamin-Trace

Mineral Premix 0.25% 5

Dicalcium Phosphate 1.10% 22

Calcium Carbonate .65% 13

7.50 % 150

This establishes that 150 pounds or 7.5% of all the ration is fixed, and thus sorghum grain and soybean meal will make up the balance (1,850 pounds) or 92.5 %.

To determine the amount of protein in the fixed portion, we should proceed as follows:

Fixed Ingredient % In Ration Lbs/Ton

Alfalfa Meal 5.00% x .17 = .85

Salt 0.50 x 0 = 0

Premix 0.25 x Negligible = 0

Dicalcium Phosphate 1.10 x 0 = 0

Calcium Carbonate .65 x 0 = 0

Total protein in fixed portion .85

Alfalfa meal is the only ingredient in the fixed portion having protein value.

Fourteen (14) pounds of protein is required for each 100 pounds of ration.

To establish the number to apply in the square block in Figure 1 for determining

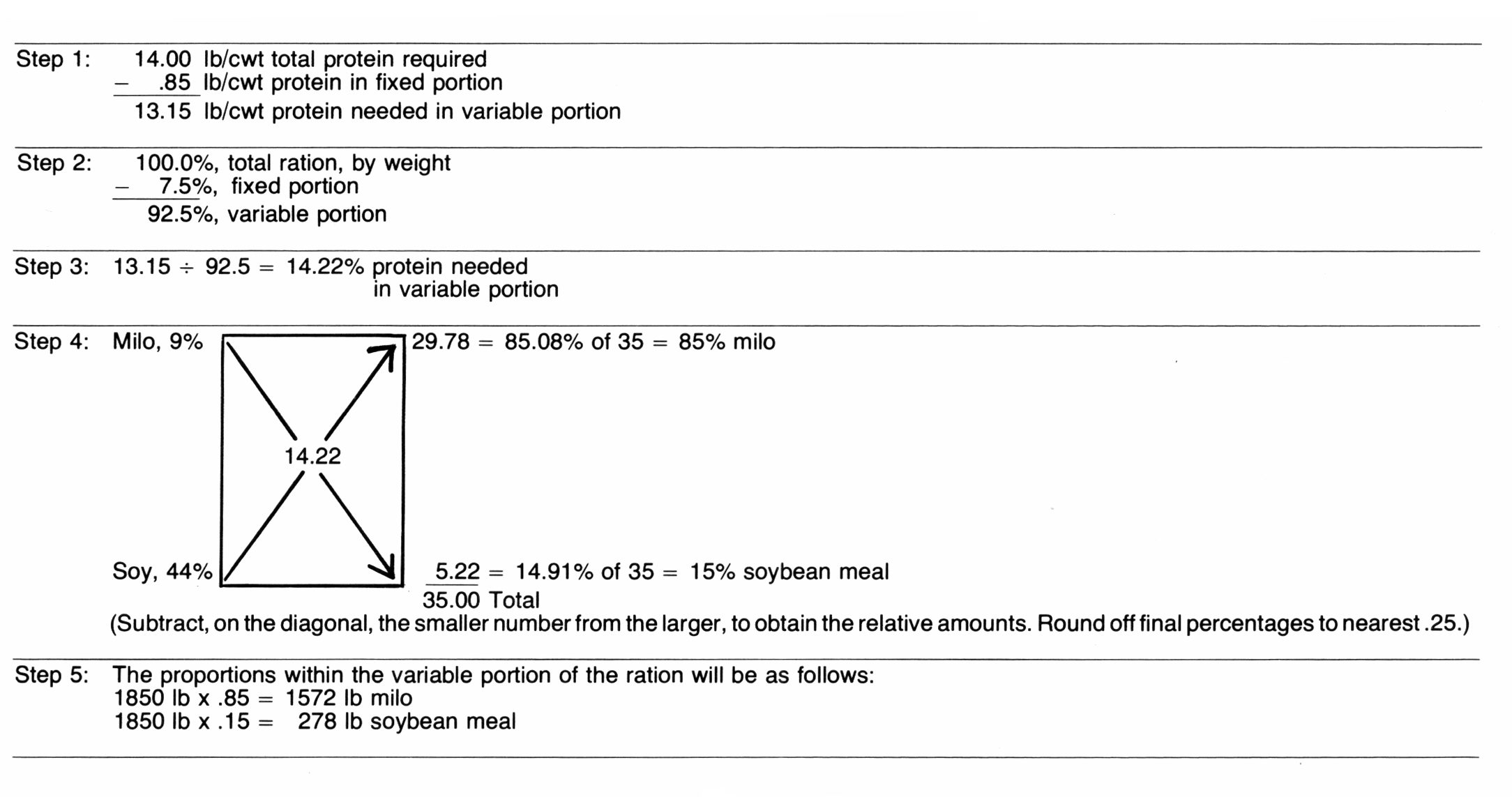

variable portions of sorghum grain and soybean meal, this procedure may be used:

14.00 pounds protein required from 100% of ration

-.85 pounds available in fixed portion of 7.5%

13.15 pounds needed from 92.5% of ration.

(100.0% —7.5%) = 92.5% of ration.

13.15 / 92.5 = 14.22

This establishes that 14.22 % protein is needed from 92.5 percent of the ration to

maintain a 14.00 % crude protein content of the total (100 % ) ration. The ration

is then calculated as shown in Figure 1. Sometimes minor adjustments are necessary.

This does not say that we must go through the entire procedure. The procedure simply

indicates values to guide us into near proximity in meeting the nutritional requirements.

We can make adjustments to correct deficiencies as long as other deficiencies or excesses

are not created. The completed ration is shown in Table 4.

Producers who wish to calculate their own rations should acquaint themselves with

the basic fundamentals of nutritional requirements for various sizes and ages of swine.

The producer should also be knowledgeable of the various ingredients commonly used

in swine rations.

There are a number of rations using feedstuffs usually available in Oklahoma which

have already been calculated. These rations can be found in Extension Fact Sheets

F-3500, “Swine Nutrition;” F-3504, “Feeding Wheat to Hogs;” F-3650, “Managing the Sow and Litter;” F-3651, “Managing the Herd Boar;” F-3653, “Management and Nutrition of the Bred Gilt and Sow;” and F-3654 “Management of Growing-Finishing Swine. “ Several swine rations can also be found in Pork Industry Handbook Fact Sheet 23, “Swine Rations.”

Table 3. Average Nutrient Content of Common Feedstuffs

| Ingredient | ME kcal/lb. | Crude Protein % | Calcium % | Phosphorus % |

|---|---|---|---|---|

| Alfalfa meal, dehydrated, 17% | 1020 | 17.00 | 1.30 | 0.23 |

| Barley | 1275 | 11.70 | 0.06 | 0.23 |

| Corn, Yellow | 1500 | 8.80 | 0.01 | 0.25 |

| Fat, Animal | 3550 | - | - | - |

| Meat and bone meal, 50% | 1100 | 50.00 | 8.10 | 4.10 |

| Milk, dried skim | 1520 | 33.30 | 1.25 | 1.00 |

| Sorghum Grain | 1425 | 9.00 | 0.02 | 0.27 |

| Oats | 1220 | 12.00 | 0.08 | 0.33 |

| Oat groats | 1500 | 16.00 | 0.07 | 0.40 |

| Peanut meal, solvent | 1320 | 47.00 | 0.20 | 0.65 |

| Soybean meal, 44% | 1475 | 44.00 | 0.25 | 0.60 |

| Soybean meal, 48.5% | 1520 | 48.50 | 0.20 | 0.65 |

| Sugar | 1383 | - | - | - |

| Tankage | 980 | 60.00 | 4.00 | 2.60 |

| Wheat, hard winter | 1500 | 12.20 | 0.05 | 0.35 |

| Wheat bran | 890 | 15.00 | 0.08 | 1.15 |

| Wheat middlings | 1300 | 16.00 | 0.05 | 0.80 |

| Wheat, dried | 1445 | 12.00 | 0.90 | 0.70 |

| Calcium carbonate | - | - | 38.00 | - |

| Dicalcium phosphate | - | - | 22.00 | 18.50 |

| Dicalcium-monocalcium phosphate | - | - | 17.00 | 21.00 |

| Deflourinated phosphate | - | - | 32.00 | 18.00 |

| Steamed bone meal | - | - | 24.00 | 12.00 |

Table 4. Completed Ration.

| Ingredient | % of Ration | Lbs. Per Ton | Lbs. Protein | Lbs. Ca. | Lbs. Phos. |

|---|---|---|---|---|---|

| Alfalfa Meal | 5 | 100 | 17 | 1.3 | 0.23 |

| Salt | 0.5 | 10 | |||

| Vitamin-trace mineral premix | 0.25 | 5 | |||

| Dicalcium Phosphate | 1.1 | 22 | 4.84 | 4.07 | |

| Calcium Carbonate | 0.65 | 13 | 4.94 | ||

| Total Fixed Portion | 7.5 | 150 | 17 | 11.08 | 4.3 |

| Sorghum Grain, 9% | 78.6 | 1572 | 141.48 | 0.31 | 4.24 |

| Soybean Meal, 44% | 13.9 | 278 | 122.32 | 0.69 | 1.67 |

| Total Ration | 100 | 2000 | 280.8 | 12.08 | 10.21 |

| Calculated Analysis % | 14.04 | 0.6 | 0.51 | ||

| Requirements % | 14 | 0.6 | 0.5 |

William G. Luce

former Extension Swine Specialist