Design of Rainwater Harvesting Systems in Oklahoma

Introduction

Rainwater harvesting is the process of capturing, channeling, and storing stormwater runoff for later use. Ideas and technologies of harvesting rain date back more than 4,000 years in areas such as Rome, the Middle East, and China. Ancient societies left evidence of agricultural dams and runoff control methods, as well as reservoir or cistern construction in urbanized areas. As of 2004, an estimated 100,000 residential rainwater harvesting systems were in use in the United States and its territories (TWDB, 2005).

Rainwater harvesting systems can be easily implemented at the home, commercial, and community level. The two basic types of rainwater harvesting collection systems, cisterns and rain barrels, essentially differ because of the volume of water to be collected. These methods of collection and storage augment municipal and well-water supplies, reduce flooding and erosion, improve water quality, and reduce water bills.

Uses of harvested rainwater include irrigation, washing cars, flushing toilets, and drinking water. Atmospheric contaminants such as, vegetation overhang, infrequent rains, dust accumulation, roof material, and bird and rodent droppings, can be carried into the system by rainwater. Therefore, if used for drinking water or flushing toilets, the water must be treated in accordance with state and federal drinking water regulations. Treatment methods include, but are not limited to, debris filtration and various purification methods such as chlorination or UV treatment to achieve disinfection.

Design and Sizing

The five main components of a rainwater harvesting system are (1) conveyance, (2) storage, (3) overflow, (4) outlet, (5) delivery. In addition, a first-flush diverter can be installed for improved water quality. Before implementing a rainwater harvesting system, it is important to understand and consider the function of these components, as well as familiarizing oneself with local plumbing, building, neighborhood, and environmental codes. The limiting factors in most rainwater harvesting applications are the space available for storage, cost and aesthetics. Several factors must be considered when installing a system including contributing rooftop area, rainfall patterns, and anticipated usage.

Different approaches to rainwater harvesting are taken in different parts of the country. To begin a rainwater harvesting project, consider the following:

- How will the harvested rainfall be used?

- How reliable will you need the system to be?

- What is the size of the catchment area that you have or need?

- Where is the catchment area located relative to the intended use?

- What size and type of storage do you have/need to purchase for the harvested rainfall?

The catchment area should be calculated based on the footprint created by the roof and not by the square footage of the roof surface. Be sure to use roof surfaces as near as possible to the planned cistern location, to shorten pipe runs. Because precipitation and water demand (except for in-home demand) are very uneven during the year, the cistern size is based upon monthly average precipitation and demand. These can be obtained from Table 1 by multiplying your average annual precipitation at your location by the percentage of rain during the identified month desired for using the system.

The gallons collected from a particular area per month is calculated by the following;

- G = 0.6 x P x A x E

where G is the gallons of water harvested per month, P is the monthly precipitation in inches, A is the roof footprint in square feet, 0.6 is a conversion factor that converts among inches, feet, and gallons, and E is the efficiency of the system (which is assumed to be 0.9, or 90 percent, in the absence of other information). Efficiency is important to include in a system because not all of the water that falls on a rooftop will be captured due to leakage, impact splash, first flush diverters, and evaporation. An excessively steep catchment area or an intense rainfall event may further decrease capture estimates due to gutter overflow.

Example: Designing a System

Joe Homeowner wishes to collect precipitation to water a vegetable garden covering 1,500 square feet. The OSU county Extension agent tells him he should apply an inch of water to the garden each week between June 1 and Sept. 1, and that the average annual rainfall 30 inches. Joe calculates that he will need to collect 4,114 gallons (see example calculation below) to water the garden during each month.

Water need per month = 1/12 ft/week x 4.4 wks/month

x 1,500 square ft x 7.48 gal/cubic ft

= 4,114 gallons

However, during the month with the least rainfall (July or August), the garden still gets 2.4 inches of rain (30 inches per year times 8 percent, which is the percentage of average percentage of annual rainfall in July). If we assume that all this rain occurred over multiple weeks during the month (which may or may not be a good assumption during the summer in Oklahoma), then the rainfall will provide:

2.4 in x 1 ft/12 in x 1,500 sq ft x 7.48 gal/cubic ft = 2,244 gallons

where 2.4 inches is the monthly rainfall, 1,500 square feet is the area of the garden, and 1/12 and 7.48 are conversion factors.Therefore, the total volume of rainwater that must be captured during July or August is:

Gallons used – gallons from rainfall = 4,114 gallons – 2,224 gallons = 1,870 gallons

This means that Joe will need a cistern, or cisterns, with a combined storage volume of at least 1,900 gallons. By rearranging the equation for G presented above, the catchment area needed to collect that much water in the month with the least rainfall (in this case July or August) would be:

A = 1,870 gallons / ((30 x 0.08) x 0.6 x 0.9) =

1,443 square feet of catchment

where G is 1,870 gallons, 30 inches is the annual rainfall; 0.08 or 8 percent is the monthly percentage of rainfall in July or August (from Table 1); 0.6 is a conversion factor that converts among inches, feet and gallons; 0.9, or 90 percent is the efficiency factor E; and A is the catchment area. Therefore, Joe will need to collect from a roof area with a horizontal projection of at least 1,500 square feet to cover his monthly water needs. He decides to collect from the roof of his barn, which has 1,600 square feet of roof area and is just above where he wishes to install his cistern. (Adapted from Rupp 2006).

Table 1. Oklahoma average monthly rainfall distribution. (Oklahoma Climatological Survey 2002)

| Month | Percentage of annual rainfall |

|---|---|

| January | 0.04 |

| February | 0.05 |

| March | 0.08 |

| April | 0.09 |

| May | 0.14 |

| June | 0.12 |

| July | 0.08 |

| August | 0.08 |

| September | 0.11 |

| October | 0.09 |

| November | 0.07 |

| December | 0.05 |

Source: (Oklahoma Climatological Survey, 2002)

Table 2. Round cistern storage capacity for cisterns with various heights and diameters (in

gallons).

| Height | 6-foot | 12-foot | 18-foot |

|---|---|---|---|

| Diameter | Diameter | Diameter | |

| 6 | 1269 | 5076 | 11421 |

| 8 | 1692 | 6768 | 15227 |

| 10 | 2115 | 8460 | 19034 |

| 12 | 2538 | 10152 | 22841 |

| 14 | 2961 | 11844 | 26648 |

| 16 | 3384 | 13535 | 30455 |

| 18 | 3807 | 15227 | 34262 |

| 20 | 4230 | 16919 | 38069 |

Source: (TWDB, 2005)

Storage Tank

The storage tank, which is sometimes called a cistern, is the primary storage component of the system and is usually the most expensive component of the rainwater harvesting system. Material, size, and location of storage tanks are dependent upon the anticipated purposes of the collected rainwater. To enhance the effectiveness of potential collection, the storage tank must be sized accordingly. The capacity of the tank should be in proportion to the purpose estimated monthly demand, the location of later use, the monthly rainfall in inches per year, and the size of the catchment area. Cistern storage tanks come in various sizes. Table 2 shows the capacity of round cisterns with varying dimensions.

Whether to have the storage tank below or above ground is a function of surrounding

landscape, underground utilities, existing downspouts, cost, structural support of

the surrounding foundation of soil, and aesthetic preference of the landowner. Below

ground storage tanks should have manhole covers to ensure safety, yet maintain their

accessibility for cleaning and upkeep. They should be sealed in order to prevent inadvertent

entrance of surface or groundwater. Keep in mind the likelihood of buoyancy of an

underground storage tank when empty. If the storage tank is empty and water infiltrates

the ground around it, it could force the tank out of the ground.

Observe the structural support of the foundation for an above ground storage tank.

The ground should be flat and able to withstand the weight of the storage tank at

full capacity. It is important to consider the placement of your cistern to prevent

settling resulting from improper foundation preparation. Remember, one gallon of water

weighs 8.34 pounds so even with a small system of 6 feet by 6 feet, the total weight

is more than 5 tons when full. This necessitates a proper foundation be installed

before the cistern is put in place. If you are unsure of the capacity of a concrete

foundation to support the weight of your full cistern, please consult an engineer.

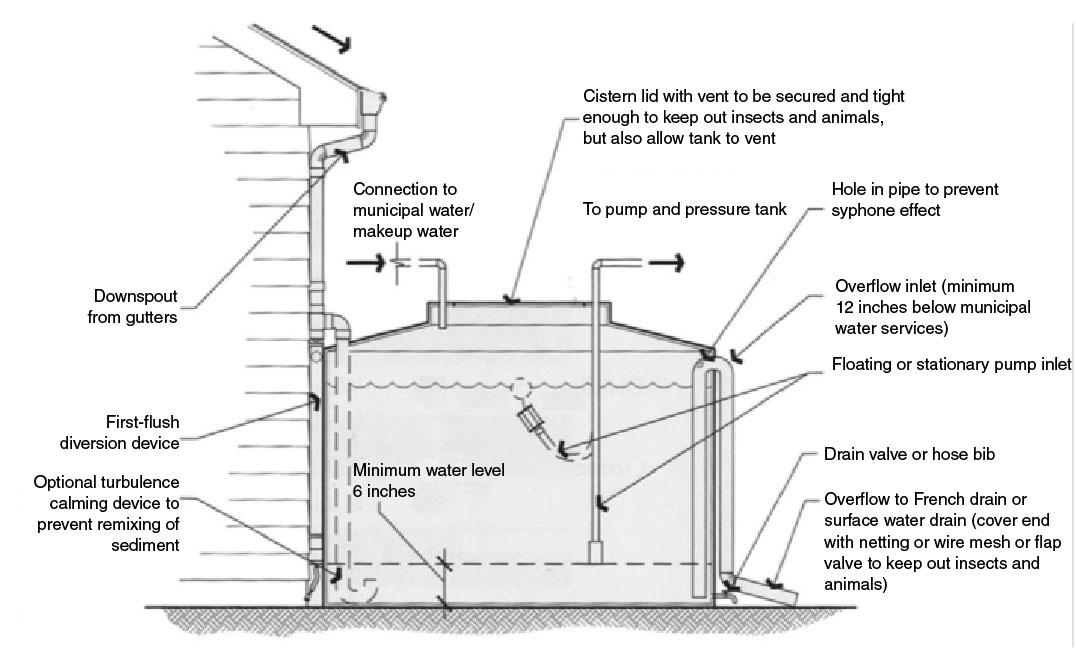

To prevent algae growth and degradation due to UV rays, above ground storage tanks should be opaque, heavily tinted, painted, or have sun barriers. Storage tanks are available in a variety of materials, including plastic, fiberglass, wood, concrete and galvanized metal. They should be sturdy, watertight with a smooth interior surface, and sealed with non-toxic, waterproof materials. Special storage tank materials are required when the harvested rainwater is to be used to supply drinking water due to the possibility of leaching. Each type of material has different benefits depending on your aesthetic needs, climate, and location of the tank. Figure 1 is a general diagram of an above ground storage tank. To discourage mosquito breeding, the cistern should also have screened vents installed.

Figure 1. Above ground water harvesting system diagram. Source: (Kinkade-Levario, 2004)

First Flush Diverters and Inlet Protection

Varying degrees of contaminant removal may be required, depending on the water’s use. For most situations, a screen filter at the gutter inlet can be used to remove large debris such as leaves, sticks, or pieces of roofing material from the roof runoff. Dust and bird droppings also accumulate on roof surfaces between rainstorms. The first part of the rooftop runoff, which is called the “first flush,” often contains higher concentrations of contaminants than rooftop runoff from later in the storm. This first flush may be diverted away from the cistern by a device known as a first flush diverter.

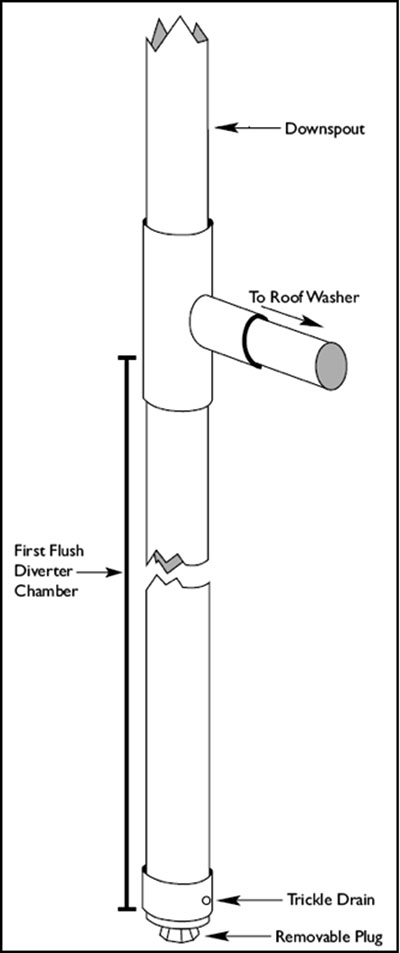

A common first flush diverter is shown in Figure 2. Water will not begin to flow into the cistern until the diverter has filled completely. A trickle drain or clean-out valve ensures an empty chamber for subsequent rainfall events. Effectively, the contaminated water is sealed off or siphoned from the next flow of rains that will enter the cistern. A general rule of thumb is to divert at least 10 gallons per 1,000 square feet of catchment area. Recommendations for minimum first flush diverter lengths are shown in Table 3.

Figure 2. First flush diverter (Rupp, 2006).

Table 3. Rainwater harvesting first flush diverter recommended lengths (Rupp, 2006).

| Pipe Diameter | Chamber Length |

|---|---|

| (inches) | (inches/Gallon) |

| 3" | 32.75" |

| 4" | 18.5" |

| 6" | 8.25" |

| 8" | 4.63" |

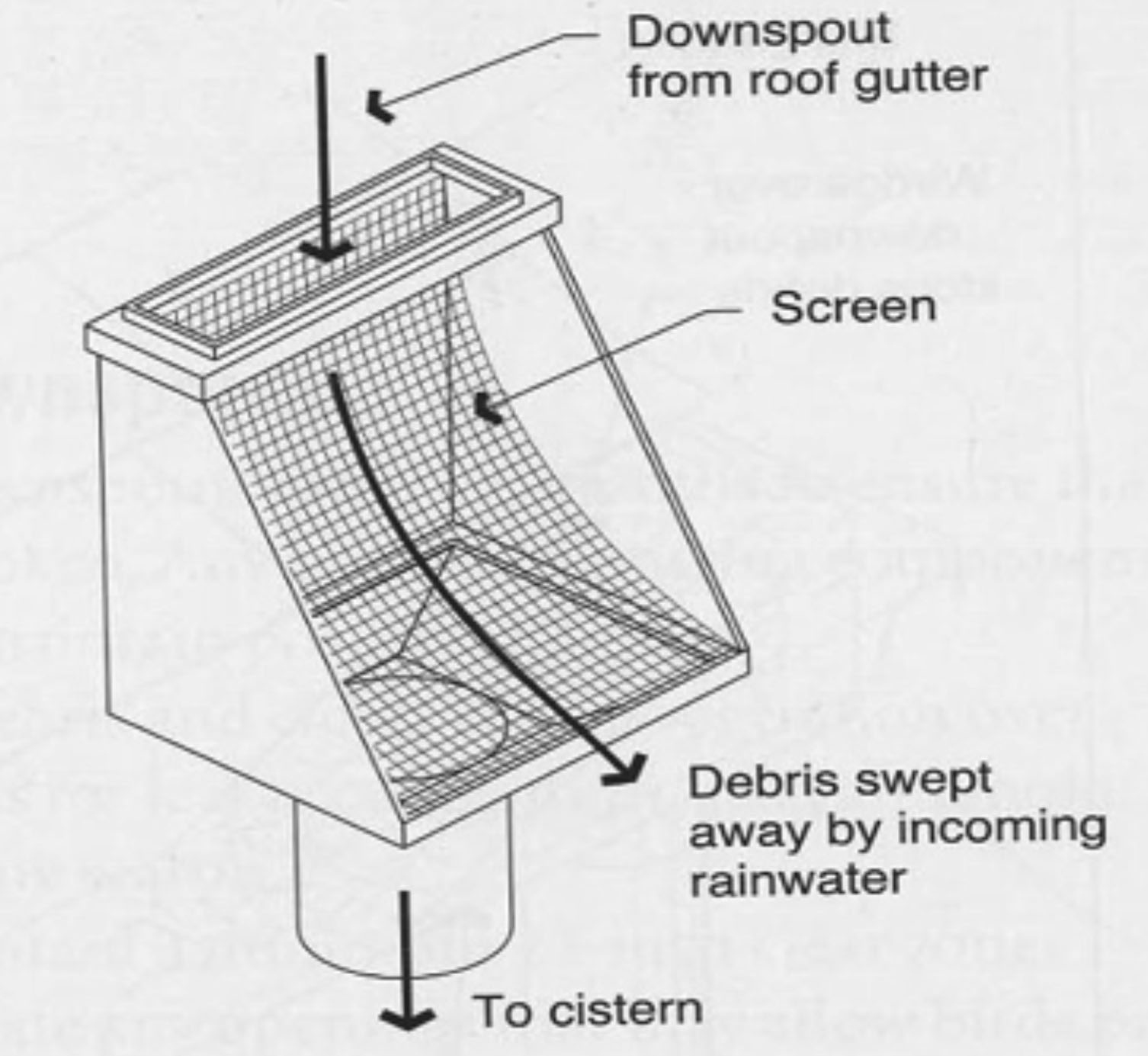

Gutter screens and roof-washers (Figure 3) are often used in addition to first-flush diverters to prevent mosquito breeding and sediment buildup in the cistern. The proper placement for a roof washer is between the first flush diverter and the cistern. The roof washer contains a screen that will filter out large debris such as twigs and leaves. Various devices can be constructed by the homeowner or purchased commercially for this purpose. Characteristics of precipitation can affect collection such as frequency, volume, duration and intensity.

A turbulence calming device, or calming inlet, may be used to minimize bottom sediment disturbance where the rainwater enters the tank. It is another safeguard to ensure an appropriate quality of water. This device can be seen in Figure 1.

Figure 3. Roof washing system for rainwater harvesting. Source: (Kinkade-Levario, 2004)

The Conveyance System

The gutter conveyance system is composed of a series of gutters, downspouts and pipes that conveys precipitation from the roof through the piping and to the cistern. The Uniform Plumbing Code (UPC) recommends that a gutter system be able to carry the runoff of the 100-year/1-hour rain event (Pushard undated). Existing gutters can be easily retrofitted to distribute more rainwater through various fixtures and to the cistern; this may require additional structural support from the building to the gutter system. The most common materials used for the gutter and piping system are PVC, seamless aluminum, and galvanized steel. The following are some general guidelines to keep in mind when designing and installing your guttering and pipe system:

- Slope gutters 0.5% (1 in/16 ft)

- Place gutter hangers 3 feet on center

- Use expansion joints in gutters 60 feet or longer

- 1 downspout per 50 feet of gutter length

- Slope horizontal conveyance pipes 2% (1 inch/4 feet)

- Horizontal conveyance pipes should have cleanouts every 100 feet

- Limit horizontal conveyance pipe bends to 45°

Source: (Sustainable Building Sourcebook, 2000)

The Overflow Pipe

When the cistern has reached capacity, a bypass or overflow pipe is necessary to direct continuing water flow away from the full cistern, while also protecting the area from erosion. The overflow pipe, installed near the top of the cistern, allows excess water to leave the cistern when needed. It is required to handle the same flow as the gutter system in order to be effective. Be sure that overflow is diverted away from any building foundations, but not directly to impervious areas. The overflow can be directed to a small rain garden.

The Outlet Pipe and Distribution System

The outlet pipe, installed at least 6 inches above the bottom of the cistern, is used to draw water from the bottom of the cistern to the distribution system that ultimately delivers the captured rainwater to its desired location. A pump may be necessary to provide adequate pressure to draw water for some applications. Solar pumps are available for locations without electricity. The exact design of the distribution system will vary depending on the intended use of the harvested rainwater.

Economics of Rainwater Harvesting

The economic savings potential of installing a system depends upon the amount of water stored, the value of water at a particular location, and the intrinsic value associated by the user with using rainwater for a particular use. For instance, harvested rainwater may have an added value over tap water when used for urban irrigation because of actual or perceived benefits of using harvested rainfall to grow their plants. Installing a system will reduce utility bills, depending on how much and to what use the water is allocated. Not all states allow rainwater to be captured and used for private or commercial use, so it is important to check state regulations before purchasing equipment.

The single largest expense is generally the storage tank, and the cost of the tank is based upon the size and the material. Costs range from a low of about $0.50 per gallon for large fiberglass tanks up to $4.00 per gallon for welded steel tanks. For those desiring professionally installed materials, costs range from $3.50 to $12 per foot of gutter, including materials and installation, in 2004. The range for pump costs runs from $385 for the low end tankless pump, to more than $1,000 for the combined price of a high-end pump and pressure tank (TWDB 2005). Buried cisterns are more expensive than those used above ground due to the larger size and multiple “moving parts.” Installation of buried cisterns can also be expensive. A common cistern shared by multiple properties may result in considerable economies of scale because there is only one excavation, one tank or set of tanks, and one pump (TWDB 2005). Over time, routine maintenance and replacement of filters or other parts will be required as well.

As of March 2012, Oklahoma does not provide tax incentives concerning rainwater harvesting. However, the neighboring local and state governments of Texas and New Mexico offer various tax exemptions, rebate programs, and other financial incentives to individuals that install rainwater harvesting systems.

Rain Barrels

For residential lots, rain barrels are a simple and lower cost solution for homeowners to conserve water. The most common size of residential rain barrels is a 55-gallon barrel (as shown in Figure 4), but barrels can range from 40 to 300 gallons. Rain barrels have become more popular among the general public, and as of March 2011, pre-constructed systems are available at lawn and garden stores for between $100 to $200. If you would like to build your own there are also online companies that will sell you a do-it-yourself kit. However, with a little time and effort you can build your own system just as easily as buying one. Oklahoma Gardening features two episodes on “How to Build a Rain Barrel” that can be viewed at the following websites. These short episodes show the step-by-step instructions on how to build a residential rain barrel.

Figure 4. Residential rain barrel in Stillwater, OK.

It is important to remember to utilize mosquito screens to prevent mosquitoes from breeding within the rain barrel. This can be done by installing a 1 mm or smaller screen at any point where standing water could be exposed to the outside environment. Rain barrels can also be painted to reflect the homeowners’ sense of style (Figure 4).

Maintenance

Rainwater collection and storage facilities require a variety of routine maintenance. After every storm event while the system is in use, the first flush diverter should be cleaned out. Semi-annual maintenance should be completed in mild weather at the end of the summer and the end of winter. Since Oklahoma has very hot summers and cold winters, it is important to inspect the system to ensure that no damage has occurred due to extreme temperatures during these seasons. At least once a year, the following routine activities will need to be completed:

- Inspection and repair of vent screens.

- Removing debris from the roof, leaf guard, gutter, gutter screen, roof washer, and first-flush diverter.

- The storage tank will need to be drained and emptied of accumulated sediment every few years.

- Inspection and servicing of pumps.

- Empty the rain barrel during the winter season to prevent damage from freezing.

- The tank can be cleaned out by letting it soak in a 5 percent bleach solution and then rinsing the tank out afterwards.

Oklahoma Example

The rainwater harvesting system shown in Figure 5 is located at the Xeriscape Demonstration Garden in Edmond that was designed and constructed by the City of Edmond in cooperation with the Oklahoma Cooperative Extension Service. The Xeriscape Garden at Bickham-Rudkin Park located at 33rd St. & Rankin was designed to demonstrate effective water management strategies within a residential landscape. Those strategies include water conservation (Xeriscape), rain water capture for use in the landscape, reduced volume and rate of stormwater runoff, and improved water quality.

Figure 5. Rainwater harvesting system capable of capturing 2,200 gallons at the Xeriscape Gardens in Edmond, OK.

Though Edmond, which is located in Oklahoma County, receives on average 36 inches of annual precipitation, it doesn’t always fall during the hot summer months when it is needed by many plants. During the summer months, as much as 50 percent of the total treated water supply in Edmond is used to irrigate landscapes, and on hot, dry days that figure can reach 80 percent.

This cistern system is able to capture the runoff from a rainfall event of up to 3.6 inches or 2,200 gallons total. The total catchment area of this system is 1,100 square feet of rooftop runoff. This water is then stored for later irrigation needs. This system utilizes the rain in the cistern first and then switches to municipal water for the remainder of the water needs. The items required for the systems are listed below in Table 4 along with the total cost.

System materials and total costs for the rainwater harvesting system at the Xeriscape Demonstration Garden in Edmond, Oklahoma:

- 1-½ HP submersible pump

- 2- 1200 gal. storage tanks

- 1-floating filter intake

- 1-pump controller with run dry protection

- 1-Overflow siphon

- 1-calming inlet

- 1-backup inlet valve for alternate source water

- 1-Tank level indicator

- 1-first flush diverter

- 1-down spout debris diverter

- 1-Vent cap

- 4-4” bulkhead fittings

- 4-1 ¼ bulkhead fittings

- 1-1 1/4 “ wye strainer

- 2-1 ¼” brass ball valves

- 2-3/4” brass ball valves

- All necessary pipe and fittings

- Total Material Cost: $4,400

- Total Labor Cost: $4,600

- Total Costs: $9,000

In summary, installing a rainwater capture system, either on a large or a small scale will translate into water conservation, and may translate into dollar savings and increases in property value. Installing a rainwater harvesting system is also a great way to reduce stormwater pollution.

References

Kinkade-Levario, Heather. 2004. Forgotten Rain: Rediscovering Rainwater Harvesting.

Landers, Jay. 2006. Let it Rain. Public Works Magazine. July.

Oklahoma Climatological Survey. 2002.

Pushard, Doug. Undated. Residential Gutter Sizing. Harvest H20.com.

Rupp, Gretchen. 2006. Montana State University.

Texas Water Development Board. 2005.