Dehydrator Optimization: Reduction of Energy Use and Carbon Emissions

Food dehydration is an age-old process that is extremely popular today. While production of canned foods is on the decline (Steel Works, 2011), production of dehydrated foods is experiencing a resurgence (Cosgrove, 2010). Jerky (especially beef) continues to be a favorite in Oklahoma, while dehydration of fruits, vegetables and spices are increasing.

Dried foods are inherently stable and safe, but these properties come at a cost. Large quantities of energy are needed to remove the water, and energy use has an obvious environmental impact. Options must be explored to reduce the energy needs and environmental impact of dehydration. This fact sheet describes one method that can be used to reduce energy consumption and carbon emissions associated with food dehydration.

Waste Heat Recovery

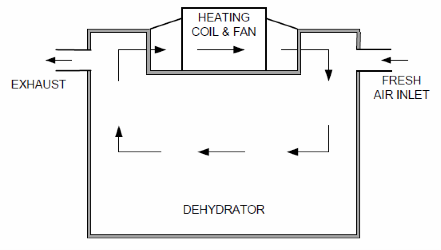

A simple schematic of a conventional dehydration chamber is shown in figure 1. Air in the dehydrator is heated by circulation through a heating coil. Fresh air is brought in through a duct in the side of the chamber and exhausted through a similar duct in the other side of the dehydrator. The exhaust air contains waste heat that can be recovered using a heat exchanger (Krokida and Bisharat, 2004). Heat exchangers are devices used to transfer heat from a source to a sink. Heat exchangers can be observed in everyday equipment like the radiator of an automobile, or the coils of an air conditioner.

Figure 1. Conceptual side view of conventional dehydrator.

A special type of heat exchanger has been developed for modern air-conditioned homes that are built with virtually air-tight exterior envelopes. This heat exchanger, known as a Ventilation Heat Recovery (VHR) unit, is designed to capture waste heat in the home ventilation system exhaust stream and use it to preheat incoming fresh air. VHRs are mass produced by several companies (see side bar on page 4) and used in new home construction to provide energy savings and improve indoor air quality. Figure 2 shows an example of a VHR designed for home use that is rugged, durable, cleanable and inexpensive

Figure 2. Typical VHR unit used to recover waste heat.

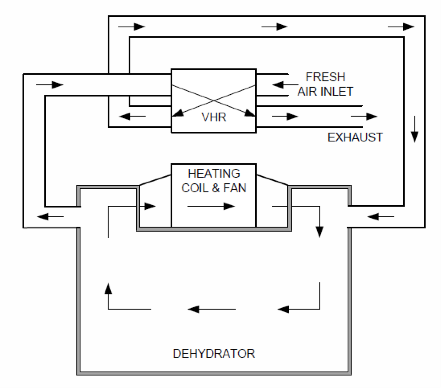

Flexible, insulated ventilation ducts can be used to connect a VHR unit to a dehydrator. Figure 3 shows a schematic of how a VHR may be connected to a dehydrator. Fans in the VHR move the air through the unit. Some VHRs have variable speed fans, which can be adjusted to optimize the ventilation rate. The next section describes the results of a study to test the performance of a dehydrator with a VHR installed.

Figure 3. Conceptual side view of dehydrator with VHR unit installed.

Example of Dehydrator Waste Heat Recovery

A low-cost home-built dehydrator (Bowser, 2011) was outfitted with a VHR unit (Fantech model SHR 2004, Lenexa, Kansas) and tested on cilantro (Coriandrum sativum). Cilantro was fresh-cut by hand, water-washed and dripped-dry prior to dehydration on perforated trays. The drying temperature was set at 165 degrees Fahrenheit. A complete description of the test is given in Bowser et al. (2011).

Table 1 shows results of dehydration tests with and without the VHR unit installed. The relative performance number (see column 2 in table 1) gives an indication of how efficiently energy was used in the system (referenced to system performance without a VHR). A higher value of relative performance indicates a better use of energy.

Table 1. Dehydrator performance with and without a VHR unit.

| Condition | Relative Performance | Time to Dry Cilantro to 10% m.c., hr |

|---|---|---|

| No VHR | 1.0 | 7.86 |

| VHR Installed | 1.38 | 5.69 |

The relative energy efficiency of the dehydrator improved 38 percent when the VHR was installed. Also, the time to dry the product to 10 percent moisture content was decreased by 28 percent.

Table 2 shows calculated greenhouse emissions for the dehydrator based on an annual operation of 1 batch (225 pounds initial product weight) of cilantro per day for 220 days. The temperature set-point of the dehydrator was 165 degrees Fahrenheit. Carbon emissions equivalent (CO2e) of the system was reduced by an estimated 34 percent by installing the VHR unit.

Table 2. Estimated greenhouse gas emissions (annual) for dehydration of cilantro with and without a VHR unit.

| Emissions at given operating conditions, tons CO2e | ||

|---|---|---|

| Emissions source | No VHR | VHR Installed |

| Purchased electricity | 4.6 | 3.4 |

| Natural gas | 15.4 | 9.7 |

| Combined emissions (total) | 20.0 | 13.1 |

Economic Analysis

A financial analysis of a dehydrator with an installed VHR unit was determined using the assumed system costs and calculated savings shown in Table 3. Calculated savings are based on the difference between the costs of operation of the dehydrator with and without the VHR. Simple payback for the investment requires about 125 hours of dehydrator operation (22 batches of cilantro at 225 pounds/batch). Net present value for the VHR installation based on 1 batch of product per day and 220 days per year is $51,806 (assuming no residual value for the VHR unit and no maintenance costs). For some products and dehydrators, the processing time may not significantly change after installing a VHR. For this case, simple payback due to energy and carbon emissions savings alone would be 1.5 years with a net present value of $4,112.

Table 3. Estimated value of inputs used in an economic analysis assuming a discount rate of 7% and a period of 5 years.

| Input item | Value | Annual value w/o VHR |

|---|---|---|

| Natural gas | 0.030 $/KW•hr | $2,539.63 |

| Electricity | 0.104 $/KW•hr | $141.48 |

| Plant operation | 25.00 $/hr∗ | 1,729 hr |

| Carbon emissions | 10.00 $/ton CO2e∗∗ | 20 ton CO2e |

| Installed cost of VHR system | $1,500 |

| Input item | Annual value with VHR | Annual Savings, $ |

|---|---|---|

| Natural gas | $1,606.20 | 933.43 |

| Electricity | $102.48 | 39.00 |

| Plant operation | 1,252 hr | 11,925.00 |

| Carbon emissions | 13.1 ton CO2e | 69.00 |

| Installed cost of VHR system |

*estimate of hourly operation expenses for a small dehydration facility.

**August 2011 value of carbon credits per metric ton (Carbonfund.org)

Conclusion

As energy, labor and equipment prices continue to rapidly increase, the efficiency of a food dehydration system is becoming more important. Environmental stewardship is also a factor that should be weighed when considering operations of dehydration equipment. Ventilation heat recovery units are now available off-the-shelf and may be quickly installed on most dehydrators. For the example described above, the VHR paid for itself after processing 22 batches.

Depending on the particular dehydration equipment installed, the value of production time, energy costs, and value of carbon credits, a ventilation waste heat recovery unit may be a profitable investment. Call or e-mail the Robert M. Kerr Food & Agricultural Products Center ((405) 744-6071, fapc@okstate.edu) to request assistance with your decisions involving the purchase, installation and operation of VHR equipment for food processes.

Manufacturers of Ventilation

Heat Recovery (VHR) units:

American Aldes Ventilation Corporation

4521 19th Street Court E., Suite 104

Bradenton, FL 34203

Phone: 800-255-7749; 941-351-3441

Fax: 941-351-3442

Aprilaire, Research Products Corp.

P.O. Box 1467

Madison, WI 53701

Phone: 800-334-6011

Fax: 608-257-4357

Broan-NuTone, LLC.

P.O. Box 140

Hartford, WI 53027

Phone: 800-558-1711

Fantech

10048 Industrial Blvd

Lenexa, KS 66215

Customer Service:

Phone: 800-747-1762; 913-752-6000

Fax: 800-487-9915; 913-752-6466

RenewAire, LLC

4510 Helgesen Drive

Madison, WI 53718

Phone: 800-627-4499

Fax: 608-221-2824

Suncourt Inc.

500 West Second Avenue

P.O. Box 40

Durant, IA 52747

Phone: 800-999-3267

More Information

If you would like guidance calculating the carbon footprint of your food manufacturing facility or products, please call the Robert M. Kerr Food & Agricultural Products Center 405-744-6071 or e-mail fapc@okstate.edu to request assistance.

References

Bowser, T.J. 2011. Meat dehydrator construction and operation manual.

Bowser, T.J., R.S. Frazier, Kakarala, R.R. 2011. Improvement of efficiency and environmental impact of a low-cost food dehydrator. submitted to The Open Food Science Journal, Bentham Science Publications, www.bentham.org/open/index.htm.

Cosgrove, J. 2010. The future of dehydrating and freeze drying.

Krokida, M.K., G. I. Bisharat, G.I., 2004, Heat Recovery from Dryer Exhaust Air. Drying Technology. 22(7):1661-1674.

Steel Works, 2011. Canned food alliance (CFA) program overview.

Timothy J. Bowser

FAPC Food Process Engineer

R. Scott Frazier

Biosystems & Ag Engineering, Energy Systems Engineer