Corral and Working Facilities for Beef Cattle

The primary reasons for constructing a corral and working facility are to observe cattle closely, perform routine health functions, and improve labor efficiency. A good working facility is merely an extension of a well-planned corral which matches the site and existing structures. The importance of site selection cannot be overstressed. Consider drainage, prevailing winds, nearby allweather roads, and utilities, i.e. electricity and water. A corral is often built to meet current needs, but it should also provide for easy expansion.

Working Chute

The heart of a corral is the working chute and crowding pens. Desirable characteristics for a working chute include:

- Curved

- Totally enclosed sides

- Sloping sides

- Overhead restrainers

- Minimum of 20 feet long

- Rough concrete floor

The working chute should be curved with solid sides to restrict the cattle’s vision (Figure 1). Cattle move more freely when they cannot see the cattlemen or the squeeze chute until they are within a few feet of the end of the working chute. If a balky animal requires prodding, it is a short distance from the squeeze chute (or headgate) to any location beside the curved working chute. Consequently, a herd of cattle can be worked in less time with a curved working chute compared to a straight chute.

Sloping the sides of the working chute is desirable because the animal’s feet and legs are confined to a narrow path. This reduces the ability of an animal to turn around. Sloping sides are more adaptable to cow-calf operations because different sizes of cattle can be worked efficiently in the same chute. Recommended widths for the bottom and top of working chutes are listed in Table 1. For exotic breeds weighing more than 1200 pound cattle, the width dimension should be increased two inches. To accommodate exotic bulls, it may be necessary to increase width dimensions by four inches.

Overhead restrainers prevent cattle from rearing up and turning around or falling over backward in the chute and are strongly recommended for working chutes with totally enclosed sides. Restrainers are generally located 60 inches above the chute floor but can be made adjustable to suit any size of animal. Overhead restrainers are most effective if adjusted to keep the animal’s head down (Figure 2). Without overhead restrainers, emergency release panels are desirable. Emergency release panels are side panels that can be opened to release animals that fall down in the chute and become lodged.

A working chute should be capable of confining at least three head of cattle for efficient labor utilization. A length of 20 feet should be sufficient to accommodate three or four mature cows. This minimum length allows one person operating the crowding area to keep the working chute charged without delays in receiving cattle at the squeeze chute.

A concrete floor in the working chute and crowding pen provides an all-weather surface and aids in sanitation. A concrete floor can be readily cleaned after working cattle to aid in preventing spread of disease. A rough finish on the concrete floor is required for good traction.

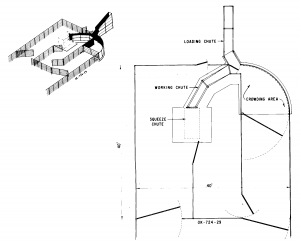

Figures 1 and 2.

Table 1. Corral and Working Facilities Dimensions.

| To 600 lb | 600-1200 lb | Over 1200 lb | |

|---|---|---|---|

| Holding area sq ft/head | 14 | 17 | 20 |

| Crowding pen sq ft/head | 6 | 10 | 12 |

| Working chute with vertical slides | |||

| Width | 18" | 24" | 28" |

| Length (minimum) | 20' | 20' | 20' |

| Working chute with sloping sides | |||

| Width at bottom inside clear | 13" | 15" | 16" |

| Width at top inside clear | 20" | 24 | 28" |

| Length (minimum) | 20' | 20' | 20' |

| Working chute fence | |||

| Recommended minimum height | 45" | 50" | 60" |

| Depth of posts in ground (minimum) | 30" | 30" | 30" |

| Corral fence | |||

| Recommended height | 60" | 60" | 60" |

| Depth of posts in ground (minimum) | 30" | 30" | 30" |

| Loading chute | |||

| Width | 26" | 26" | 26"-30" |

| Length (minimum) | 12' | 12' | 12' |

| Rise, in/ft | 3 1/2 | 3 1/2 | 3 1/2 |

| Ramp height for: | |||

| Stock trailer | 15" | ||

| Pickup Truck | 28" | ||

| Stock Truck | 40" | ||

| Tractor-Trailer | 48" | ||

| Double-deck trailer | 100" |

Crowding Area

The crowding area is a specialized holding pen which funnels cattle into the working and/or loading chutes. A well-designed and constructed crowding area reduces the labor required to work cattle—enabling one man to keep the working chute charged. Desirable characteristics for a crowding area are:

- Circular shape

- Totally enclosed sides

- Solid crowding gate

- Rough concrete floor

A circular crowding pen with solid sides and crowding gate is effective because the only escape route visible to the animal is through the working or loading chute. To further encourage cattle to evacuate the crowding pen, the crowding gate is intermittently moved toward a closed position. This effectively restricts the cattle to successively smaller areas until they move into the chute. The concrete floor is desirable to provide an all-weather surface and sanitation.

The circular crowding pen normally has a 12-foot long, swinging crowding gate. A quarter-circle

crowding area with 12-foot crowding gate can handle up to eight mature cows. For large

operations, half-circle and three quarter circle crowding areas are common.

Loading Chute

A loading chute is a must at feedlots. It can also be beneficial to cow-calf operations. Consider an adjustable height loading chute to accommodate stock trailers as well as trucks. If possible, locate the loading chute outside the corral and pasture to keep trucks out of lots and reduce the spread of diseases. Desirable characteristics for a loading chute are:

- Curved approach

- Totally enclosed sides

- Telescoping side panels

- Self-aligning dock platform

- Circular crowding area

- Located near scales

A curved approach and solid sides restrict cattle’s vision. Similar to working chutes, cattle move more freely into loading chutes when they cannot see the cattlemen or truck until just before loading. Solid sides are also useful for unloading because the cattle cannot see the ground and move readily down the chute and ramp. Telescoping side panels on the loading chute are used to close the gap between chute and truck. A self-aligning dock platform that swivels eliminates the need for backing the truck perfectly square into the dock. A circular crowding area restricts the cattle to a small holding area with the loading chute as the only escape route.

Platform scales should be located near the loading chute to weigh cattle directly

into or out of the chute. Scales should not be placed in line with the loading chute.

While scales should be easily accessible to vehicles which have weights used for testing

and calibration, they should not be used as alleyways. Many scales are located outside

of the corral for use by trucks and other farm equipment.

Holding Pens

The overall corral plan normally dictates the size and shape of holding pens. However, planning before construction will insure greater utilization of all holding pens. One of the most common errors in holding pen design and layout is insufficient holding space for sorting cattle as they exit the squeeze chute. A good corral layout allows sorting from the squeeze chute without disrupting the flow of cattle entering the working area. Consider placing a few small pens near the squeeze chute for confining sick or injured animals.

Holding pens interconnected with a common alleyway provide ideal sorting capabilities.

Cattle can be held in the alleyway and sorted into any of the adjacent holding pens.

Maximum width for a common alleyway used to sort cattle is 12 feet. The alleyway can

also be used to confine cattle for spraying.

Consider future expansion when locating holding pens. Additional holding pens need

to be near working and loading areas or directly connected by an alleyway. Holding

pens located too far from the working chute will reduce labor efficiency.

Working Areas

The working area is the area surrounding the exit end of the working chute. On smaller cow-calf ranches, the working area consists of a headgate fastened securely to the end of the working chute. On larger beef cattle operations, the working area is frequently a well-equipped hospital with squeeze chute, storage space, and refrigerator all enclosed within a building.

Headgate

A headgate is acceptable for routine health functions, whereas a squeeze chute allows complete control of the animal reducing the potential for injury to both cattle and cattlemen. Factors to consider before selecting either a headgate or squeeze chute include purchase cost, size and type of beef cattle operation, and availability of labor. Even though a headgate is normally satisfactory for most small cow-calf ranches, a shortage of labor can force the smallest operations to utilize a squeeze chute.

The three most common types of headgates used on a working chute or a squeeze chute are the self-catch, stanchion, and guillotine. Advantages of a self-catch headgate include: easy to operate, works cattle fast without balking, and allows cattle to easily exit. If properly adjusted, it seldom chokes cattle. Disadvantages of a self-catch headgate are: not well suited for horned cattle, requires a head table and nose bar to secure the animal’s head, can cause severe shoulder bruises when cattle lunge at the cocked headgate, and sometimes allows an animal to escape without being caught. The stanchion headgate is also simple and fast to operate and seldom chokes cattle if properly adjusted. Disadvantages of the stanchion headgate are: requires a head table and nose bar, possible shoulder bruises as cattle lunge toward the open stanchion, inability to prevent an animal from escaping without being caught, and frequent tripping of cattle as they walk through the headgate. The guillotine headgate holds the animal’s head secure and lessens shoulder bruises; but it is difficult to operate, can cause choking and is slower because cattle balk instead of moving forward.

Hospital Area

A well-designed hospital area has:

- Ample storage space

- A refrigerator

- Adequate ventilation

- A well-drained concrete floor

- Potable water

- Electricity

- Overhead lighting

Storage space is utilized for both medical supplies and equipment. A refrigerator is recommended to store perishable medicines. Space should also be allotted for record-keeping. Record-keeping in the hospital area will provide accessible data that can be used to analyze effectiveness of past treatments. Overhead ventilation can clear the air of smoke from branding or vapor and odor from insecticides. A well-drained concrete floor is helpful in maintaining sanitation and reducing the potential spread of diseases. Use a 1/4 inch per foot slope. The floor should have a roughened finish to provide good traction.

The most important facilities to have available in all working areas from the simplest design to the most elaborate hospital area are potable water and electricity. Potable water must be available at all times during cattle working to wash veterinary equipment and general cleanup. Electricity is necessary for lights and electrical equipment such as branders, dehorners, clippers and refrigerator.

Corral Plans

Figures 3, 4, and 5 illustrate three corral plans which are available through your Oklahoma Cooperative Extension Center. These plans are suitable for all sizes of operations—small cow-calf, large ranches, small feedlots, and backgrounding operations. Each plan features a circular crowding area, curved working chute, location for a squeeze chute or headgate, space for a palpation cage, loading chute and holding pens. Cattle can be sorted in the alleyway connecting the pens and crowding area and with the gate at the head of the squeeze chute. The loading chute adjoins the crowding area to provide efficient loading because the cattle are forced directly into the loading chute using the crowding gate.

(Figure 3) Plan No. OK-724-26 can be designed to match herd sizes from 70 to over 400 head. The rectangular corral can be built with a variety of pen sizes—ideal for sorting cattle. The holding pens near the squeeze chute provide an excellent location for sick pens. A platform scale can be located near the crowding area to weigh incoming and outgoing cattle. The pen and working area arrangement can be incorporated into many existing facilities. This corral can be used as a hospital area, receiving facility, backgrounding lot or combination for smaller feedlots and stocker operations. The working area can be constructed under a roof to ensure all-weather usability. The smaller holding pens can also be placed in a building to provide environmental protection for sick animals. Feed bunks can be constructed on the outer fence lines to accommodate delivery from mixer trucks.

The pie-shaped corral, (Figure 4) Plan No. OK-724-25 can be designed to match herd sizes from 70 to over 400 head. For smaller herds, the corral can be built with only a couple of pie-shaped pens, the crowding area, curved working chute, loading chute, and holding pen surrounding the working area. The five pie-shaped pens around the perimeter of the sorting alley are capable of holding 150 head of mature cattle. Adding pens to the outer perimeter of the central five pens can increase holding capacity to over 400 head. Pie-shaped holding pens are ideal for spraying, but additional fencing is required compared to rectangular pens of the same area.

(Figure 5) Plan No. OK-724-29 is designed for a group of 25 to 50 head, but can be expanded to suit groups of about 75 head. This plan can also be incorporated in existing corrals. This plan has an ideal loading arrangement, good sorting capabilities, and good spray areas. Disadvantages include limited expansion capabilities and no ideal location for scales.

As mentioned previously, these plans can be obtained through the Oklahoma Cooperative Extension Centers. For persons outside of Oklahoma, write to:

Plans and Building Information

Extension Agricultural Engineering

214 Agricultural Hall

Stillwater, Oklahoma 74078

Figures 3 and 4.

Figure 5.

Summary

A corral and working facility are only as good as the planning prior to construction. Utilize a working chute, crowding area, loading chute, and holding pens to closely observe cattle and improve labor efficiency while performing routine health and management functions. Labor efficiency is achieved through design features which are based on animal behavior. These features include a curved working chute, semi-circular crowding area, and loading chute. Safety for both cattlemen and cattle should be considered throughout the planning phase. Finally, the importance of selecting proper dimensions and a good site cannot be overemphasized.

Raymond L. Huhnke

Extension Agricultural Engineer

Sam Harp

Extension Agricultural Engineer