Calf Preconditioning: A Comprehensive Overview

- Jump To:

- Beef Calf Preconditioning

- Preconditioning Practice Improve Health and Performance

- Healthy Calves Exhibit Improved Carcass Quality and Value

- Branded preconditioning programs capture market premiums

- Budgetary considerations for preconditioning beef calves

- Building a preconditioning budget

- Summary

Beef Calf Preconditioning

Within the beef industry, "preconditioning" typically refers to the implementation of management practices aimed at enhancing calf immunity and ensuring nutritional needs are met. These management practices also include mitigating the adverse effects of impending stressful events, such as weaning, marketing, transportation and commingling. In conventional cow-calf production systems, calves are weaned between 6 and 8 months old. The preconditioning period occurs during the time following weaning and ends when the calves are marketed. The initiative to standardize and promote improved management practices for beef calves originated at Oklahoma State University, where animal scientists and veterinarians convened to address challenges in the stocker and feedlot cattle sectors. This collaboration led to the fusion of the terms "pre-vaccinating" and "conditioning," giving rise to the term "preconditioning" (Gill, 1967). The term "pre-vaccinating" had previously denoted the practice of vaccinating calves before weaning and/or shipping, while "conditioning" encompassed various management practices, such as weaning, castrating, dehorning and bunk training.

The preconditioning process equips calves to better handle the stressors encountered

in the subsequent stages of the beef supply chain. Research has demonstrated that

the preconditioning process leads to lower incidence of sickness and decreased medical

and labor costs associated with the treatment and management of sick calves. The presence

of healthy preconditioned calves in the market enhances the reputation of the cow-calf

producer, and in many cases,

contributes to improved herd profitability.

Numerous value-added or “branded” preconditioned calf marketing programs are now commonplace within the beef industry. These value-added programs increase the ease of effectively marketing preconditioned calves, leading to the adoption of improved management practices, increased producer involvement and increased profitability. A well-designed calf preconditioning program consists of calf vaccination, castration, dehorning and a required weaning period prior to sale of typically 45 or more days.

Deworming and bunk training are common components of many preconditioning programs but are generally not required. Calves should be vaccinated against common respiratory viruses: infectious bovine rhinotracheitis (IBR),bovine viral diarrhea virus (BVD) type 1, and type 2, parainfluenza virus type 3 (PI3), and bovine respiratory syncytial virus (BRSV). Many programs require vaccinating against the common respiratory bacterial pathogen Mannheimia haemolytica. Some bacterial pathogens, such as Pasteurella multocida and Histophilus somni, are more prevalent in certain areas, so it is important to discuss the need for additional vaccinations with a veterinarian. These viral and respiratory pathogens act in conjunction with each other to cause what is referred to as “bovine respiratory disease” (BRD). Classical BRD is characterized by an initial viral infection followed by bacterial colonization of the lungs, which leads to respiratory illness and potential death.

Many vaccine options will provide protection from all viral respiratory pathogens

mentioned. Most vaccine options include protection against viral respiratory pathogens

and M. haemolytica or other bacterial agents in a single product. Calves should also

receive a clostridial vaccine,which protects against disease caused by clostridial

bacteria, commonly referred to as “blackleg.” Most branded preconditioning programs

will require that vaccines be administered twice, where an initial vaccine is followed

by a second dose or “booster” vaccine. Reading and following vaccine labels is vital

to a successful vaccination program. The vaccine label will provide necessary information,

such as identifying the pathogens for which protection is provided,dosage, route of

administration and timing for the booster vaccination. A veterinary client/patient

relationship and veterinary consultation regarding animal pharmaceutical use are important

for a successful herd health program.

Preconditioning Practice Improve Health and Performance

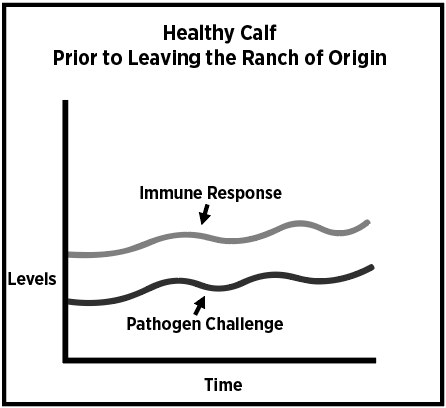

Calves receive passive immunity from the dam through the intake of colostrum, which is the initial milk produced by a cow after giving birth. Colostrum is abundant in antibodies, immunoglobulins and other immune factors, offering temporary protection to the newborn calf. The protection offered by passive immunity typically continues until the calf reaches approximately 4 months of age. As a result, calves typically maintain good health while still on the ranch of origin (Figure 1). However, as they undergo various stressors like weaning, castration, dehorning (if necessary), shipping and commingling, their immunity and disease resistance will be challenged. The implementation of preconditioning practices allows calves sufficient time to navigate and recover from these stressors and build and maintain adequate antibodies to respiratory pathogens, ensuring they are better equipped for subsequent transportation, commingling and pathogen exposure. While a natural stress response is expected, healthy calves rebound swiftly with no adverse health effects, but when calves encounter a series of stressors in rapid succession, a compounding effect may occur. This leads to impeding their ability to cope and recover rapidly, causing what is known as "chronic stress."

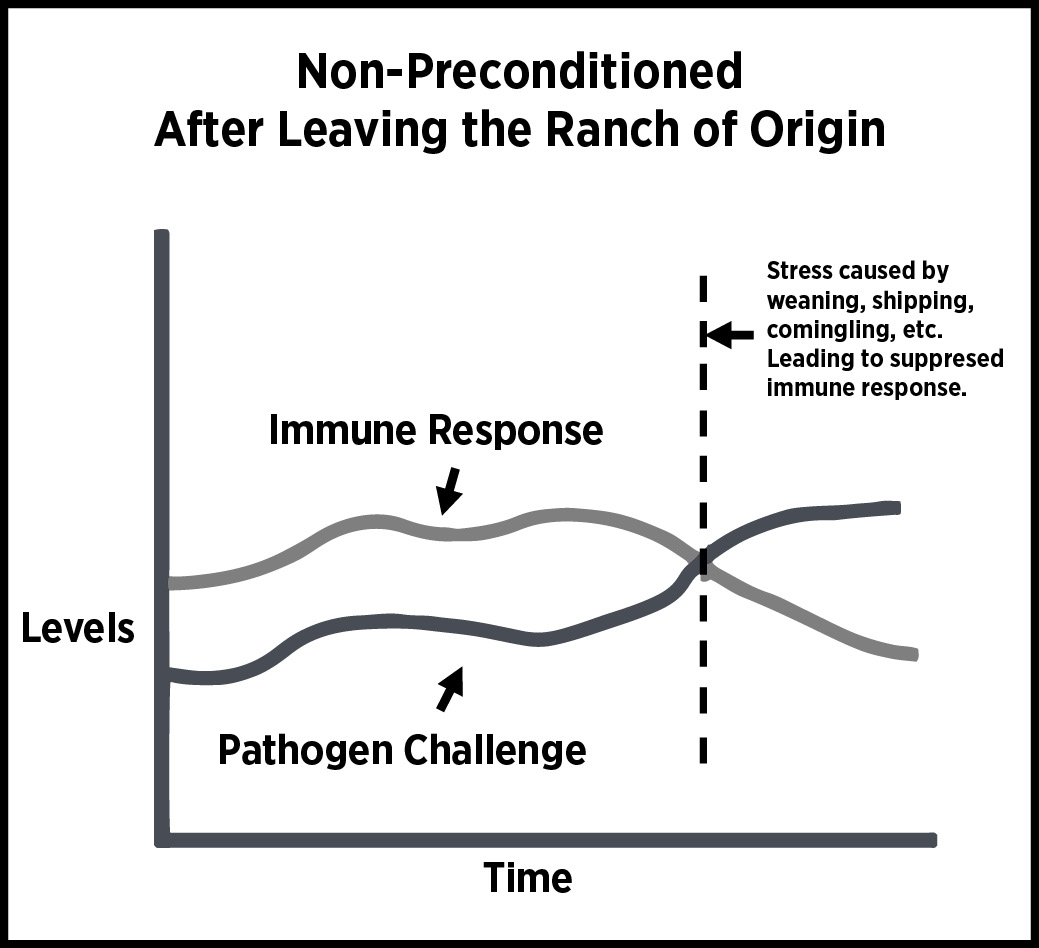

In scenarios where non-preconditioned calves ar abruptly separated from their dams, transported, sold and commingled, often within a single day, multiple stressors converge, potentially resulting in chronic stress and immune system suppression. Research has demonstrated that elevated levels of glucocorticoid hormones, such as cortisol, are released in calves experiencing chronic stress. This suppression of the immune system significantly heightens the risk of succumbing to respiratory pathogens, ultimately contributing to BRD (Figure 2).

Figure 1. A healthy calf exhibiting an adequate immune response.

Source: Soren Rodning, Adapted from the Alabama Cooperative Extension

System’s Beef Systems Short Course.

Figure 2. A non-preconditioned calf exhibiting an inadequate immune response. Source: Soren Rodning, Adapted from the Alabama Cooperative Extension System’s Beef Systems Short Course.

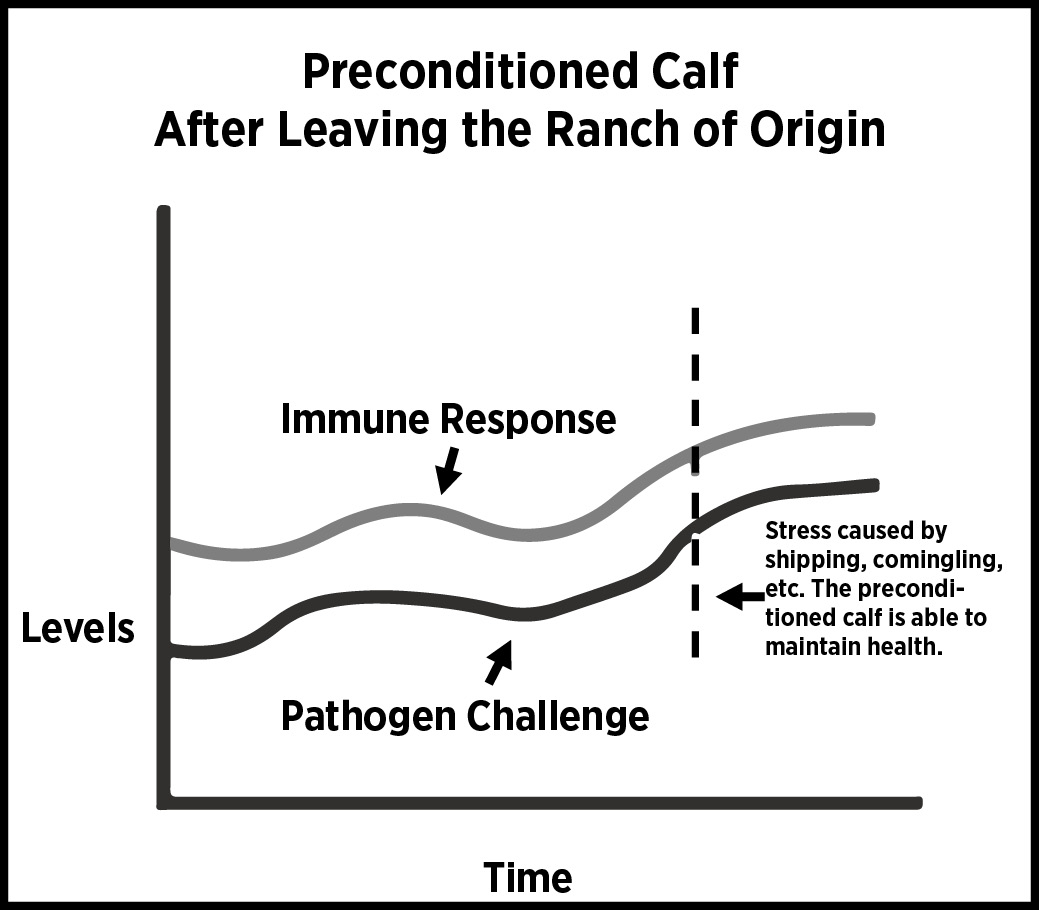

Figure 3. A Preconditioned calf exhibiting the ability to cope with an immune challenge. Source: Soren Rodning, Adapted from the Alabama Cooperative Extension System’s Beef Systems Short Course.

Previous research has indicated that preconditioning leads to improved immune function and reduces instances of stress and pathogen-related sickness.

- A feedlot study indicated that preconditioned calves gained 0.4 pounds more than non-preconditioned calves (Cravey, 1996).

- During a feedlot receiving study, preconditioned steers gained 0.77 pounds more and demonstrated a 90% reduction in sickness compared to non-preconditioned steers (Richeson et al., 2012).

- Heifers weaned for at least 45 days demonstrated reduced sickness rates (5-10%) compared to unweaned heifers (35-43%) during a 42-day feedlot receiving study (Step et al., 2008)

Administering vaccines to unvaccinated calves following arrival to the feedlot often does not effectively prevent illness, as the calves have already been exposed to pathogens before feedlot entry. Richeson et al. (2015) reported that sickness rates in newly received, high-risk stocker calves acquired from auction market facilities were not significantly reduced by administering respiratory vaccines. Unfortunately, once unvaccinated calves are commingled at sale facilities and then shipped, the incubation period for respiratory pathogens has already begun. Studies have hypothesized that once calves arrive at the feedlot, vaccine administration may detrimentally affect calves that are stressed and likely already experiencing varying levels of immunosuppression (Wilson et al., 2017). The frequency of calf illness is highly variable and unique to each farm, ranch, marketing, shipping, receiving, stocker and feedlot situation. A sound preconditioning program does not guarantee that all calves will remain healthy. However, preconditioning practices provide calves with increased preparedness and the greatest potential to avoid illness during the next phase of life.

Healthy Calves Exhibit Improved Carcass Quality and Value

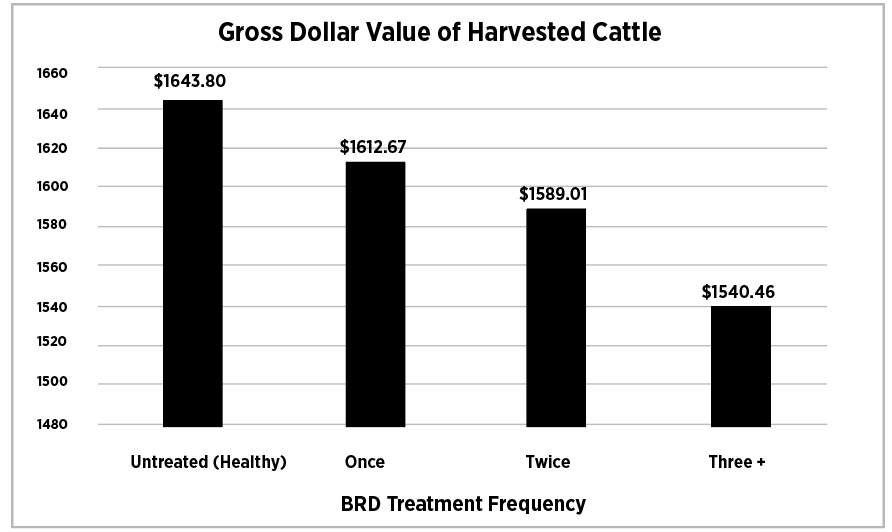

Preconditioning practices have been demonstrated to improve health, and calves that remain healthy during the feedlot phase yield carcasses of greater quality and yield compared to calves requiring medical treatment for respiratory illness. A feedlot study by Wilson et al. (2017) reported untreated steers and steers treated once, twice and three or more times graded 70.3%, 56.5%, 60.2% and 36.2% USDA Choice or better, respectively. In conclusion, this is an indication that healthy cattle that do not require medical treatment or are treated once and recover produce carcasses of greater value and yield greater quality grade beef compared to calves treated multiple times.

Richeson et al. (2012) observed that antibiotic costs were $18.04 lower on average for preconditioned calves compared to their non-preconditioned counterparts. Gardner et al. (1998) documented that steers with lung lesions linked to BRD demonstrated an average net return of $74 lower than that of healthy calves. In a study by Step et al. (2009), calves weaned for 45 days and vaccinated exhibited an average health cost of $4.31 per head lower than unweaned calves from the same ranch during a 42-day feedlot receiving period. Healthy calves demonstrate greater value upon harvest compared to cattle treated for BRD. In a feedlot study by Wilson et al. (2017), steers treated once, twice and three or more times for BRD exhibited differences in gross value of -$31.13, -$54.79 and ⁓$103.34 compared to untreated steers (Figure 5).

Figure 4. Actual cattle gross income of feedlot cattle treated for BRD in a 2017 OSU study. Source: Wilson et al., 2017. Effect of bovine respiratory disease during receiving period on steer finishing performance, efficiency, carcass characteristics and lung scores.

Branded preconditioning programs capture market premiums

Previous studies have indicated that preconditioned calves receive market premiums. A study by Trotter (2020) summarized price differences from 2009 to 2018 for traditionally marketed (non-preconditioned) versus value-added (preconditioned) beef calves weighing between 500-899 pounds and sold at Joplin Regional Stockyards near Carthage, Missouri. This study concluded that preconditioned steer and heifer calves sold during this 10-year data collection period received average sale price premiums of $5.12 and $3.83 (per 100 pounds of calf weight)(Trotter, 2020). Common branded beef calf preconditioning program options are highlighted in Table 2.

The Oklahoma Quality Beef Network (OQBN) Vac-45 Program is a branded program that aids beef cattle producers by providing value-added marketing opportunities for preconditioned calves. OSU Extension, Oklahoma Cattlemen’s Association and Oklahoma livestock auction facilities work in cooperation to implement OQBN, providing value-added marketing opportunities throughout the state. To qualify for the OQBN Vac-45 Program, calves must be weaned 45 days before the date of sale, castrated and dehorned. It is suggested that calves be dewormed and bunk trained. Calves must also be vaccinated twice against viral respiratory and BRD pathogens and twice against clostridial bacteria (blackleg vaccination) at least 21 days before sale. Calves enrolled in the OQBN Vac-45 Program are marketed via live auctions at multiple livestock auction facilities throughout the state. Calves participating in the OQBN Vac-45 Program boast an impressive history of capturing consistent market premiums compared to nonpreconditioned calves marketed in the same sales (Figure 7).

| Variable | Untreated (healthy) | Once | Twice | Three Times | Chronically ill |

|---|---|---|---|---|---|

| Beginning BW (lbs.) | 536 | 529 | 529 | 531 | 540 |

| Purchase Price ($/heifer) | 606 | 601 | 599 | 602 | 591 |

| ADG (lbs.) | 3.11a | 2.80b | 2.18c | 1.46d | 0.95d |

| Drug Cost ($/heifer) | 0.00a | 9.63b | 23.62c | 35.71d | 35.34d |

| End BW (lbs.) | 731a | 705b | 665c | 624d | 580e |

| End Price ($/heifer) | 705a | 682b | 649c | 612d | 573e |

| Net Returns Related to Untreated Heifers ($) | 0.00 | -18.61 | -51.14 | -90.50 | -111.12 |

Table 1. Economic and production effects of BRD for heifers during a 63-day preconditioning

period.

Source: Brooks et al., 2011. Economic effects of bovine respiratory disease on feedlot

cattle during backgrounding. a-e Means with different subscripts are different (P

< 0.05)

| Organization | Program Title | Webpage Link |

|---|---|---|

| Integrity Beef Alliance | Vac 60 Program | Calf Protocols | Integrity Beef, Proven Performance |

| McAlester Union Stockyards | McAlester Vac-45 Program | McAlester Stockyards |

| Oklahoma State University Extension And Oklahoma Cattlemen’s Association | Oklahoma Beef Quality Network (OQBN) Vac-45 Program | Oklahoma Quality Beef Network | Oklahoma State University (okstate.edu) |

| Organization | Program Title | Webpage Link |

|---|---|---|

| Zoetis | SelectVac Program | SelectVAC | Homepage | Zoetis SELECTVAC |

| Merck | PrimeVac Program | Cattle - Vaccines | Merck Animal Health USA |

| Boehringer Ingelheim | Market Ready Program | Market Ready® | Boehringer Ingelheim Animal Health |

| Organization | Program Title | Webpage Link |

|---|---|---|

| American Angus Association | Angus Link | Homepage | Angus Link |

| American-International Charolais Association | CharAdvantage | Charolais USA |

| American Hereford Association | Hereford Advantage Program | Hereford Advantage - American Hereford Association |

| Red Angus Association of America | Feeder Calf Certification Program (FCCP) | Value-Added Programs - Red Angus |

Table 2. Branded beef calf preconditioning programs. *This not is a complete list of all current branded beef calf preconditioning programs that are available.

Figure 5. OQBN lots and average premiums represent sales where data was collected. Premium price based on $cwt = dollar value per 100 lbs. of calf body weight. Source: K.C. Raper and D.S. Peel, Historical OQBN data collection.

Budgetary considerations for preconditioning beef calves

In 2004, the estimated average cost of a calf preconditioning program was $60 per

calf (Avent et al., 2004). Schulz et al. (2015) indicated that preconditioning program

profitability was dependent on the typical price seasonality of the cattle market.

Beef calf sale prices typically increase after October (Peel and Meyer, 2002). In

recent years, there has been a substantial rise in input costs, including feed, hay

and fertilizer. As a result, current calf preconditioning costs exhibit high variability

and are challenging to precisely estimate. Using online budgeting tools, the current

estimated total costs may be approaching $75-100 per calf (Figure 8). These costs

are subject to constant variability due to market fluctuations and dynamic feed commodity

prices. Despite the fluctuating costs, research by Williams et al. (2014) revealed

that expected net returns and the likelihood of positive net returns increased with

the adoption of multiple calf health management practices. Producers who weaned and

vaccinated calves before marketing achieved expected net returns of $28.44 per calf

with a 60% probability of positive net returns. However, those producers who not only

adopted these practices but also marketed

through a certified preconditioning program received an additional $30.29 per calf

in net returns. This resulted in an increased probability of positive net returns

reaching up to 79%. These findings emphasize the potential economic benefits of comprehensive

calf health management practices and participation in certified preconditioning programs

for producers.

The nutrition program typically makes up 45-60% of the preconditioning budget (Lalman

and Ward, 2005). Providing calves access to high-quality pasture consisting of warm

season forage (bermudagrass), winter annual forages (ryegrass, wheat, oats, rye, etc.)

or stockpiled cool season forage (fescue, brome, etc.) will result in a reduction

in feed costs versus drylot weaning/feeding programs. Fence line weaning may be a

good strategy to allow calves access to quality forage and decrease stress associated

with dam removal. The nutrition program has a direct influence on

calf body condition and future performance. Smith et al. (2000) reported that calves

classified as “fleshy” were discounted $1 to $2/cwt (dollars per hundred pounds of

calf weight). Previous research has also indicated that calves with faster rates of

gain during the preconditioning period result in slower rates of gain during the finishing

period. Ideally, preconditioning programs should target a moderate average daily gain

of 1.5 to 2.5 lbs.

Building a preconditioning budget

Calf preconditioning costs vary widely among individual ranches based on resources and geographic location, and there are many budget inputs to consider. When building a preconditioning budget, many inputs are obvious, such as feed, hay, fertilizer and vaccination costs. However, some indirect costs, such as labor and equipment depreciation, are often overlooked. Cattlemen are encouraged to consider the preconditioning opportunity cost of owning calves for at least an additional 45 days instead of marketing them with a shorter or no weaning period. OSU Extension specialists provide budget calculators for various types of operations. The Extension preconditioning budget calculator can be accessed by on the OSU Extension website. This budget calculator is a useful tool that allows cattle owners the opportunity to evaluate the potential profitability of implementing calf preconditioning practices. When using this online tool, it is imperative to enter the current costs based on the resources available near the location of the individual ranch. Resources, such as feed, hay, fertilizer and other costs, fluctuate based on many factors. Thus, there is a constant need to update and evaluate a budget prior to implementing a calf preconditioning program.

A calf preconditioning budget should provide an estimated cost and potential profit. The degree of budget complexity will vary depending on ranch resources and production goals. An example budget examining preconditioning gross revenue (Figure 7), costs (Figure 8) and profit(Figure 9) is provided below. A budget must be tailored to an individual operation, and this is an example of a budget providing general cost and revenue estimates.

| Preconditioning Management Costs | Cost |

|---|---|

| Vaccine, health supplies and medicine ($/head) | 12.75 |

| Death loss ($/head) | 0.00 |

| Labor ($/head) | 13.20 |

| Equipment ($/head) | 7.50 |

| Pasture ($/head) | 6.00 |

| Fertilizer ($/head)d | 25.00 |

| Feed/Supplement ($/head) e | 17.00 |

| Hay ($/head)f | 0.50 |

| Mineral ($/head) | 0.75 |

| Added marketing costs (tags, commission) ($/head) | 5.00 |

| Total cost ($/head) | 87.70 |

Figure 6. Estimated Preconditioning Management Costs (Example).

d.) Fertilizer cost using approximate Spring 2024 pasture blend (20-10-15) fertilizer

costs ($1,000/ton).

e.) Hay cost calculated using USDA Oklahoma Direct Hay Report cost estimates for Spring 2024.

f.) Feed cost calculated using approximate Fall 2024 calf grower ration (14-16% CP) estimates for Spring 2024.

| Non-Preconditioned vs Preconditioned Calf Value Summary ($/head) | Cost |

|---|---|

| Non-Preconditioned Calf Gross Revenue (Figure 7) ($/head) | 1416.00 |

| Preconditioned Calf Gross Revenue (Figure 7) ($/head) | 1598.08 |

| Increased Revenue (Preconditioned – Non-Preconditioned Calf) ($/head) | 182.08 |

| Preconditioning Costs (Figure 8) ($/head) 182.08 87.70 |

87.70 |

| Net Return from Preconditioning Program(Increased Revenue – Preconditioning Costs) ($/head) | 94.38 |

Figure 7. Estimated Preconditioning Program Net Return (Example).

Summary

Upon departing the ranch, calves are affected by many stressors (shipping, commingling, additional handling, pathogen exposure, etc.). Preconditioning practices, such as adequate vaccination, weaning for 45 days or more before marketing, deworming and feed bunk training, reduce stress while improving the health and welfare of beef calves. This stimulates a successful transition to the next phase of the beef production system. Bovine respiratory disease remains the leading cause of calf illness and death during the stocker and feedlot phases. Preconditioned calves enter and complete the stocker and feedlot phases with fewer instances of illness compared to non-preconditioned calves. While calves that experience illness in the feedlot may recover and exhibit compensatory gain, a reduction in performance and profitability will be observed. Preconditioned calves, especially those participating in branded preconditioning programs, consistently capture market premiums. Developing a preconditioning budget is a key component of a profitable preconditioning program, and must be tailored to a specific cow-calf operation. Preconditioning programs such as the Oklahoma Quality Beef Network’s (OQBN) Vac-45 Program aid cow-calf producers in successfully marketing calves by increasing visibility, providing educational opportunities and maintaining a reputation for healthy calves entering the market.