Containers and Media for the Nursery

Numerous types of containers and media have been developed for container growing of nursery stock. Considerable controversy exists as to what type of container or media is the ideal choice. Despite the large variety of products available to the grower, “growing success” often is contingent upon growing techniques, rather than choice of container and medium. Below are guidelines intended to guide new growers in making choices suitable for their particular nursery.

Container Size and Shape

Depth

Air filled porosity decreases as the depth of mix in a pot decreases. If the media chosen is fine textured, a lack of oxygen could occur, stunting growth potential for the nursery stock. Soil-borne diseases are also aggravated by these low oxygen conditions.

Deeper containers are best for optimum aeration and drainage. One criticism by some growers is that roots in deep containers do not grow laterally, quickly enough after planting. Therefore, plants are easily blown over. This can also occur while still potted, depending on the container dimensions (tall but not balanced by width). In conclusion, a grower may want to experiment with a few plants when more than one container style is available. Often the deepest container is too dry, while the most shallow container may be too wet after irrigation and subsequent drainage.

Width

Wide containers are less likely to topple than narrow containers; however, stability must be balanced against space efficiency. The diameter of the container has no bearing on drainage. Similar drainage patterns occur regardless of diameter in pots with the same depth. Therefore, there are no advantages to using excessively wide pots. Most growers prefer pots that are deeper than they are wide.

Volume

Size of nursery stock will dictate the necessary volume of containers. Large plants require equally large containers to prevent stunting of root and shoot growth. This can be difficult for inexperienced growers to judge. Refer to the American Standards for Nursery Stock to obtain the latest container size requirements for a specific nursery stock size.

Growers often group together plants in like size containers for more accurate irrigation and easier handling and maintenance.

Shape

The cheapest pots and easiest to stack are those which are round in horizontal cross section. Most growers select this type for the advantages given above, even though their use remains somewhat controversial. Circling roots occur and have been shown not to regain normal growth after plants are removed and planted in the ground. Despite this valid criticism, constant observation of the growth of nursery stock and appropriate action to prevent stunting can offset any permanent damage. Problems arise when nursery stock is not sold as early as anticipated. A decision must then be made to either shift plants to a size larger container or risk circling and girdling roots in the present container.

Besides these steps, square pots which tend to direct roots downwards and prevent circling roots may be chosen. Many other types of pots have been designed for the same reasons with varying success. Despite the fact that conventional containers may not grow the best plant, they are usually warranted because of the expense factor for other pot types. Also, the grower who carefully monitors nursery stock will not allow plants to grow beyond the period when permanent root damage may occur.

Drainage Holes

Quick and proper drainage is imperative for the health of most nursery stock grown in Oklahoma. Containers which provide drainage holes that straddle the bottom corner, so they are on both the bottom and wall of the pot, are ideal. Be certain that all holes are “clear.” That is, be sure that plastic is not covering areas where holes are supposed to be in preformed containers. This is not uncommon in containers which are produced in mass quantities. The recommended drainage hole area at the bottom of the pot is at least 20 percent.

Materials and Colors

The vast majority of containers used in the U.S. are plastic, specifically polyethylene or polypropylene. Although metal containers and occasionally clay are still used, they are only justified in a few specific cases.

Plastic pots can be purchased in a number of colors with green and black being the most popular. Black pots often heat up excessively in the summer and probably should be avoided in some growing areas.

Additional considerations for containers:

- must be compatible with potting machines when used

- must stack easily but also be pulled apart easily

- durable for plant production period

- some have raised rings on inside “lip” for ease in handling when wet

Growing Media

Container soils have less volume and are more shallow than field soils. Therefore, what is considered an excellent field soil may perform poorly (slow to drain) in a container. Due to poor soil aeration which leads to poor plant growth and performance, an emphasis on artificial media has occurred with little to no field soil included in the mixes.

Nursery stock can be grown in almost any material that provides anchorage, water, oxygen, essential mineral elements, and is nontoxic.

Physical properties such as color, structure, texture, behavior towards water and air all have an effect on the health of containerized plants. Chemical properties influence chemical reactions which supply nutrients to plants. Finally, biological factors, primarily microscopic organisms, largely influence the growing success of any given media. Therefore, the physical, chemical, and biological factors all interact to form a complex control over plant health.

Soil

Soil is used by a few nurserymen in Oklahoma who have access to it and prefer it, since it often supplies trace elements (micronutrients). Although soil has advantages, it is difficult to obtain a regular supply which is uniform and of high quality. Couple this with the need to pasteurize each load and disadvantages quickly mount. To further complicate this amendment, chemical imbalances in nutrients can occur after the pasteurization process. Lastly, the added weight may make shipping costly, so retaining prices at a competitive level becomes very difficult.

Sand

Sand is often used in media mixes to add bulk density and improve drainage. Choose particle sizes of 0.05 to 1.0 mm with at least 90 percent of the particles towards the finer range. No nutrients or buffering capacity are offered by sand.

Peat and Peat Moss

The names peat, peat moss, or moss peat refer to several materials that are similar in origin, but quite different in their physical and chemical properties. Peats are organic materials (plants) that depending on their degree of decomposition, are of varying value to growers. All the peats are divided into four types: 1) sphagnum peat moss, 2) hypnaceous peat moss, 3) reed and sedge peat, and 4) humus peat or muck.

Sphagnum Peat Moss. This is the most desirable of the peats and most suited in container media. It is acidic, but can be easily adjusted by a number of liming materials if necessary. It is low in soluble salts, long-lasting in the mix, uniform in composition, and effectively improves drainage and aeration, yet has good water and nutrient retention. Sphagnum peat has been shown to absorb seven times its weight in water.

Although two grades of sphagnum peat moss are available, the horticultural grade should be selected, since it is finer in particle size range and grade and most appropriate for container media.

Disadvantages to any of the peat mosses are that they are hard to wet and may shed water. Either soak the peat moss in warm water before use or add a wetting agent. Use of a wetting agent is more feasible in large scale operations.

Hypnaceous Peat Moss. This peat decomposes quicker than sphagnum peat but is still suitable for container mixes. It may be acquired from the northern states.

The last two categories of peat, reed and sedge peats and humus peat or muck, are not recommended in container media. They break down too quickly and interfere with proper aeration and drainage.

Bark

Hardwood bark is a commonly used, excellent media ingredient. Aged bark must be used due to the risk of toxicity to plants when new. Bark is aged with time (at least 30 days or longer after harvest) and leaching. Also, heat and bacterial colonization help reduce toxic effects of the bark. Additional nitrogen must be added when using bark in the mix. Bacteria immobilize and use a great deal of nitrogen making the additional amount necessary for the plants’ use.

Softwood bark is acceptable but will lower the pH of a media more than hardwood bark. Therefore, liming may be necessary except for acid loving plants.

Bark retains water, has excellent drainage, and is sterile. Some nutrients are supplied by all barks and the material is slow to decay. This is a definite advantage in a mix intended for long term use for nursery stock. Additionally, bark is lightweight which is an advantage for workers and when stock must be shipped. Bark is sometimes used alone or with sand or other media amendments.

Perlite

Perlite, heat-expanded volcanic rock, is often used for increasing aeration while lowering bulk density. Because it is so light and will float when the media is watered, it should be restricted for special uses in the nursery such as for propagation media. Perlite is not appropriate in most cases for use in container nursery mixes.

Vermiculite

Vermiculite is mica which is mined in the U.S. and abroad. It is purchased in a heat expanded form which has a high cation exchange capacity. Unfortunately, it compresses easily and is not suitable in a long term mix, such as that needed in container media. Like perlite, it is well-suited for propagation purposes in the nursery, but not for general container nursery mixes.

Manure

Manures are not recommended for use in container media. Although high in mineral elements, nutrient toxicity often occurs. After pasteurization, which is imperative due to the weed seeds and disease organisms associated with this material, excessive nutrients become available, often at toxic levels to the plants. This organic source of fertilizer has no chemical elements which cannot be supplied in chemical fertilizers. Synthetic fertilizers are easier to control and more stable and predictable (same concentration of nutrients every application).

Calculating Media Needed

Many container manufacturers provide charts for their pots indicating how many pots can be filled with a cubic yard of media. However, if containers are purchased without these guidelines or if special mix formulas, small quantities, etc. are needed, the following formula is convenient and accurate. Also, a grower can keep track of media costs invested on a per plant basis.

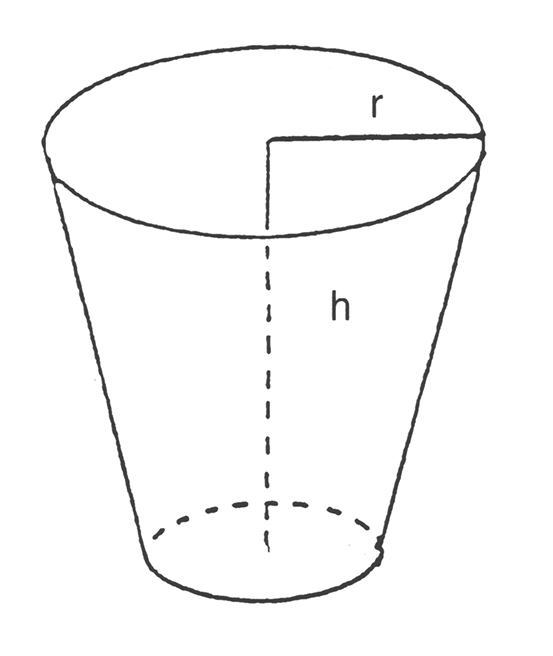

The container’s top radius (r) must be determined by measuring the diameter of the top of the pot and then dividing by two (see Figure 1). Determine the depth of the pot (h) by measuring from the center-top to bottom.

The formula for the volume (V) is:

V = (3.1416 x r2 x h)

To calculate the volume, multiply the top radius (r) by itself (r x r = r2) and then by 3.1416. Then multiply this number by the depth at the center of the pot (h). This number is the container’s approximate volume (V).

Figure 1. To determine the volume of a round nursery container, measure the diameter of its top and the height of the container (pot depth = h). Measure h in the center of the pot. The radius of the top of the container = r.

Example:

A grower needs to use one or two-gallon round pots to containerize several bare-root

plants. The grower determines the following values after measuring the containers.

| Measurement | 1 gallon | 2 gallon |

|---|---|---|

| Top diameter | 6.25* | 7.25 |

| Top radius (r) | 3.13 | 3.63 |

| Pot depth (h) | 6.75 | 7.25 |

* values represent inches

For the One-Gallon container

Volume (V) = [(3.13 x 3.13) x 3.1416 x (6.75) = 23.87 x 3.1416 x 2.25 = 207.8 cubic inches media needed per one-gallon container.

After calculations used above for the one-gallon containers, the grower finds that 300.1 cubic inches of media is needed per two-gallon container. Two-hundred bare root plants need to be containerized, with 100 of those plants needing one-gallon pots and the remainder needing two-gallon pots.

Therefore

(207.8 x 100) + (300.1 x 100) = 20,780 + 30,010 = 50,790 cubic inches of media needed

for 100, one-gallon containers and 100, two-gallon containers. One cubic yard equals

46,656 cubic inches. Cubic inches can be converted to cubic yards by multiplying by

0.00002143 or dividing by 46,656.

Take for example the above measurements of 50,790 cubic inches of media needed. This would be the same as 50,790 x .00002143 or 50,790/46,656 = 1.09 cubic yards media needed for the 200 containers. This method slightly overestimates media needed, but allows for settling once the media is in the containers. Always double check your calculations.

Testing the Media

Before a crop is planted, test the media for pH, soluble salts, and available nutrients. This can be accomplished by contacting your county Extension educator. He or she will assist you in obtaining and directing the sample to Oklahoma State University or a private lab. Growers often purchase pH meters and solubridges to monitor pH and salt levels in soils after planting.

Growers often must adjust the pH of non-soil mixes and add additional nutrients. For

instance, mixes proportionately high in peat moss or softwood bark may require dolomitic

limestone to elevate the pH if it is below 5.8. Hardwood bark and some sources of

peat may have the opposite effect creating an excessively high pH. This media then

needs sulfur or sulfur compounds to lower the pH. The pH of the soil greatly influences

the availability of nutrients, particularly trace elements. Nutrition and pH are discussed

in other literature available through your county extension agent.

Since there is such a large variety of containers and media available, topics discussed above are by no means comprehensive of the commercially available products. Refer to Extension Fact Sheet HLA-6702 for additional information regarding a container nursery.

Additional Reading

Handreck, K. and N. Black. Growing Media for Ornamental Plants and Turf. New South Wales University Press, Kensington, Australia, 1986.

Oklahoma Cooperative Extension Service Fact Sheet HLA-6702, “Locating the Nursery.”

Oklahoma Supply Companies

American Plant Products and Services, Inc.

9200 Northwest 10th Street

Oklahoma City, OK 73127

1-800-522-3376

Aqua-Hort Systems Inc.

P.O. Box 57197

Oklahoma City, OK 73157

1-800-446-1694

U.S. Companies

Belden Plastics Inc.

2582 Long Lake Road

Roseville, MN 55113

1-800-328-2603

Better Plastics Inc.

P.O. Box 420820

Kissimmee, FL 34742

Pro-Gro Products Inc.

P.O. Box 1945

Elizabeth City, NC 27906

Michael A. Schnelle

Assistant Professor

Extension Ornamentals

Floriculture Specialist

Janet Cole

Assistant Professor

Ornamental Horticulture