An Evaluation of Alternative Feed Delivery Systems for Cattle – For use in combination with the Feed System Analysis Spreadsheet

Overview

Feeding costs often represent a significant proportion of total annual expenses for a cow-calf operation. Many beef producers supplement the forage intake of their cattle with other feed sources. Supplemental feed helps to provide cattle with additional protein and energy, which are critical during winter and drought conditions when cattle need these additional nutrients to remain healthy. The Kansas Farm Management Association reported feed costs for Kansas producers represented 47.2 percent of total costs for a cow-calf operation .

When purchasing feed, producers have the option at most feed mills and some feed stores to purchase in either bagged or bulk quantities. Bagged feed is typically sold in 50-pound, non-reusable, paper, sewn bags. Bagged feed may be preferred by producers with small herd sizes who do not want to invest in the necessary equipment associated with bulk feed delivery, but the lack of equipment means more labor required to deliver feed to the cattle.

Bulk feed is often desirable for producers who have access to it and sufficient herd sizes because it typically costs $20-$40/ton less than bagged feed. However, bulk feed typically requires additional capital expenditures (feed truck, feed bins, bulk feeders) for feed delivery. Producers are faced with a wide variety of equipment options when choosing how to handle and dispense bulk feed. Because feed costs represent such a significant portion of livestock operation expenses, it is critical producers manage these costs with regard to actual feed costs, vehicle and fuel costs, and labor costs.

The Feed System Analysis Spreadsheet

The Feed System Analysis Spreadsheet (FSAS) is designed to help producers compare different bulk feed delivery systems and determine the most efficient system for their operations. This spreadsheet is designed to aid producers in evaluating the optimal mix of equipment and labor to manage annual feeding costs. The best system is assumed to be dependent on the following factors:

- Size of operation and amount fed per animal

- Labor cost/opportunity cost of time

- Equipment complements available

- Distance traveled to a feed source and cost of fuel

- Price difference between bulk and bagged feed

- Storage risks

- Capital investment required, interest rate/cost of capital

The FSAS is a free spreadsheet template. Users input data into the highlighted, orange

cells only. Non-orange cells are locked to prevent keystrokes, which may cause errors

within the spreadsheet. Producers will enter information regarding the size of their

operation and feeding quantity, vehicle and fuel information, feed prices and labor

estimates. The spreadsheet will calculate projected annual savings for a producer

considering an investment in a different feeding system, as well as the investment’s

payback period, net present value and internal rate

of return.

To begin using the template, a producer should first enter his or her financial, cattle and feed price information into the orange cells in the “Financial Information” and “Feed Prices” sections. Drop-down menus are available for many inputs. However, drop-down menus are not suitable for inputs with a wide range of possibilities. For these inputs, information should be entered manually. The spreadsheet will return an error message if an input exceeds what has been determined to be a reasonable or possible range of values.

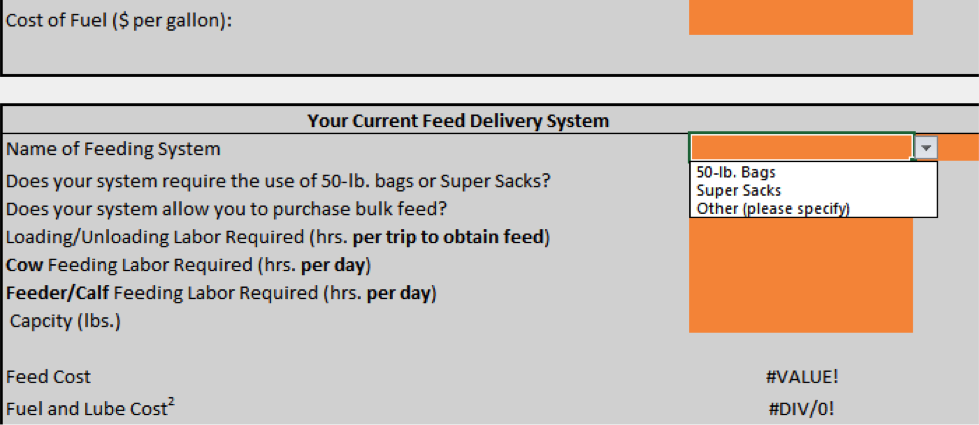

The lower half of the spreadsheet is divided into three sections addressing details of the current and prospective feeding systems. The section titled “Your Current Feed Delivery System” captures information on a producer’s current feeding program. Figure 1 shows a dropdown menu which a producer uses to select his/her current feed delivery method. The spreadsheet includes additional calculations depending on which input is selected. For example, 50-pound bags and super sacks (totes capable of holding up to a ton of feed) are more susceptible to weather and rodent damage, and the spreadsheet is designed to account for this. If a system other than 50-pound bags or super sacks is currently being used, the producer can chose the “Other (please specify)” option and name his or her feed delivery system in the orange cell directly to the right of this drop-down menu. It is also important to be mindful of the units for each input, e.g. time per day versus time per week or pounds versus tons.

Figure 1. Entering current feed system into FSAS.

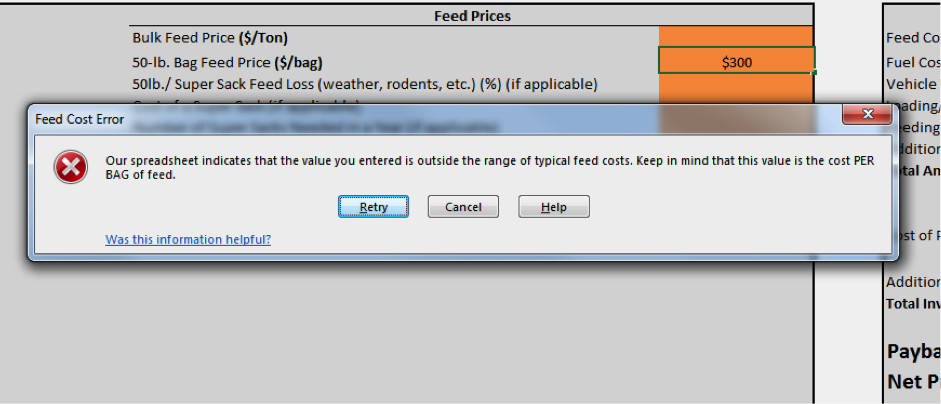

Figure 2 outlines the type of error message that will appear when an unreasonable or impossible input is entered. This example shows the message that appears when $300 is entered for the cost per 50-pound bag of feed. This specific control is designed to prevent the cost per ton from being entered by mistake.

Figure 2. Example of an error message in the FSAS template.

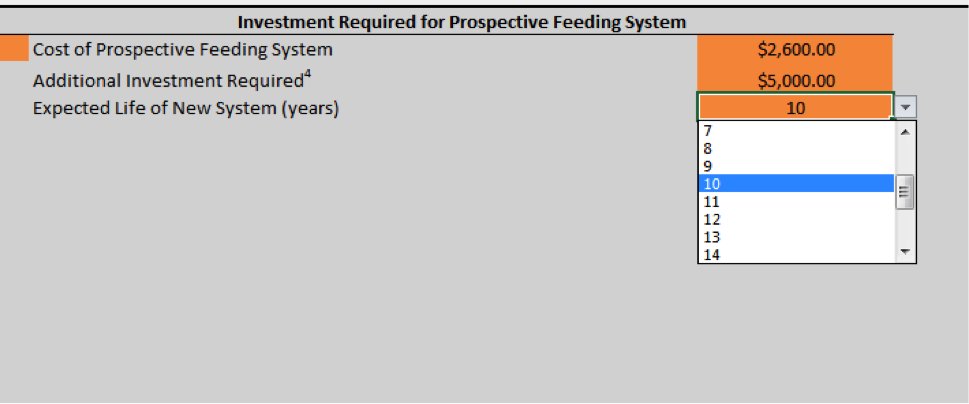

The “Investment Required for Prospective Feeding System” section of the spreadsheet is where the user inputs the expected costs associated with moving to a prospective new feeding system. The inputs in this section include the cost of the new feed delivery system, additional investment required and the expected life of the new system. Types of additional investments required may include items such as a dedicated flatbed feed truck, front-end loader, or overhead bin. Figure 3 shows an example of a user choosing the expected life of equipment for a prospective feeding system.

Figure 3. Choosing expected equipment life for a new feeding system in the FSAS

The “Prospective Feed Delivery System” section of the spreadsheet contains inputs, which are similar to the current system inputs shown in Figure 1. However, the prospective feed delivery system inputs are estimated. The accuracy of these estimates has a great impact on the accuracy of the spreadsheet’s outputs. It is important to be mindful of the units associated with each input and to be as accurate as possible. If a user does not know the correct values, he or she might start with using drop-down menus and then testing the impacts of those values on the resulting financial analysis.

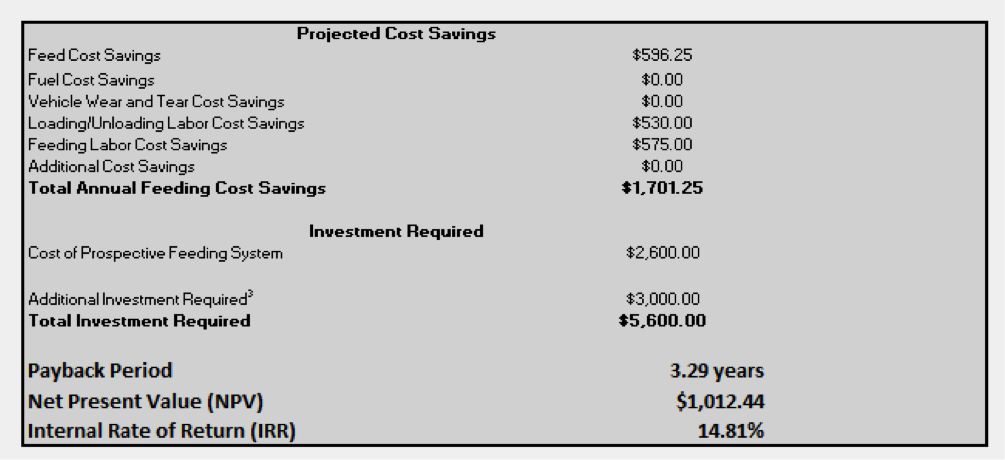

A summary of the cost savings (or additional costs) is outlined in the “Project Cost Savings” section of the spreadsheet (Figure 4). This shows the savings (or additional costs) associated with each specific line item. The spreadsheet also uses three capital budgeting evaluation tools: payback period, net present value (NPV) and internal rate of return (IRR).

Payback period is defined as the length of time it takes to recover the cost of an investment. Longer paybacks are typically not desirable for investment positions. Payback period is calculated by dividing the cost of an investment by the projected annual cash flows produced. Net present value (NPV) is defined as the difference between the present value of cash inflows and the present value of cash outflows. It often is used in capital budgeting to analyze the profitability of a projected investment or project, and returns a dollar value that represents the direct financial impact of an investment decision. IRR is a metric used in capital budgeting to measure the profitability of potential investments. IRR, by definition, is the discount rate that causes the net present value of cash flows to equal zero. IRR can be useful in comparing prospective investment decisions to one another. Generally, the higher a project or investment’s IRR, the more desirable the decision to undertake it is. Figure 4 outlines an example of the cost savings summary section of the spreadsheet when all inputs have been filled in.

Figure 4. Projected cost savings (+/-) in the FSAS

Examples of Feed Delivery Systems

The following examples of feeding systems could be analyzed using this spreadsheet. It is important to note this list is not a comprehensive list because operations tend to be unique and many different types of equipment and systems exist. Examples of feeding systems which could be used in the spreadsheet include 50-pound bags, super sacks, gravity-flow feed buggies, powered feed buggies, pickup-mounted feeders and portable, pickup-loaded feed containers. Descriptions and diagrams of these systems, as well as an outline of their associated strengths, weaknesses, opportunities, and threats are outlined on the following pages. Products shown in images are for illustrative purposes only and are not endorsements of specific products.

It should also be noted other types of equipment and accessories could be included in a feeding system. For example, an overhead bin could be used as a way for producers to have large quantities of bulk feed delivered to their respective operations. While overhead bins provide a technique for storing bulk feed on a farm or ranch, they do not provide a way to distribute feedstuffs to livestock. Additional equipment and/or processes, like the ones described on the following pages, would be needed to transport feed from an overhead bin to livestock.

50-pound Bags

A traditional way of feeding cattle and other livestock is by purchasing feed in 50-pound paper bags at the feed mill or feed store. Unless a trip to the feed store precedes every feeding, producers must unload the feed at the farm and store it in an area where it will be safe from weather and rodent damage. Bags of feed must be re-loaded and transported to livestock, where the feed is manually dispensed.

SWOT Analysis of a 50-pound Bag Feeding System

- Strengths

- Little additional investment required for handling equipment except for a vehicle if needed.

- Wide variety of feeds available in 50-pound bags at feed mills or stores.

- Can be transported using a variety of vehicles, including cars, pickups, SUVs and ATVs.

- Weaknesses

- Physical labor associated with loading, unloading and dispensing feed.

- Cost per pound or ton is higher than if feed was purchased in bulk.

- Bags are susceptible to damage from weather, as well as rodents and other vermin.

- Producers must navigate their way through livestock to reach bunks or troughs, which can be dangerous, especially with large animals like cattle.

- Bags must be disposed of once emptied, and are often burned or thrown away, raising potential environmental concerns.

- Opportunities

- Niche markets where livestock producers purchase a small quantity of diverse or unique feedstuffs.

- Potential use for bag as mulch or compost.

- Threats

- Potential for increased regulation from environmental agencies regarding excess paper waste.

- Age of agricultural operators is increasing and excess labor can be very strenuous on older individuals.

- Increased cost of paper manufacturing or shortage of wood products in the future.

- Feed loss due to inherent weather, rodent damage, or unintentional bag breakage.

Despite the higher cost per pound, labor requirements, safety risks and environmental concerns associated with 50-pound bags, they remain a very popular method for handling and dispensing feed, especially for small operations and small herd sizes.

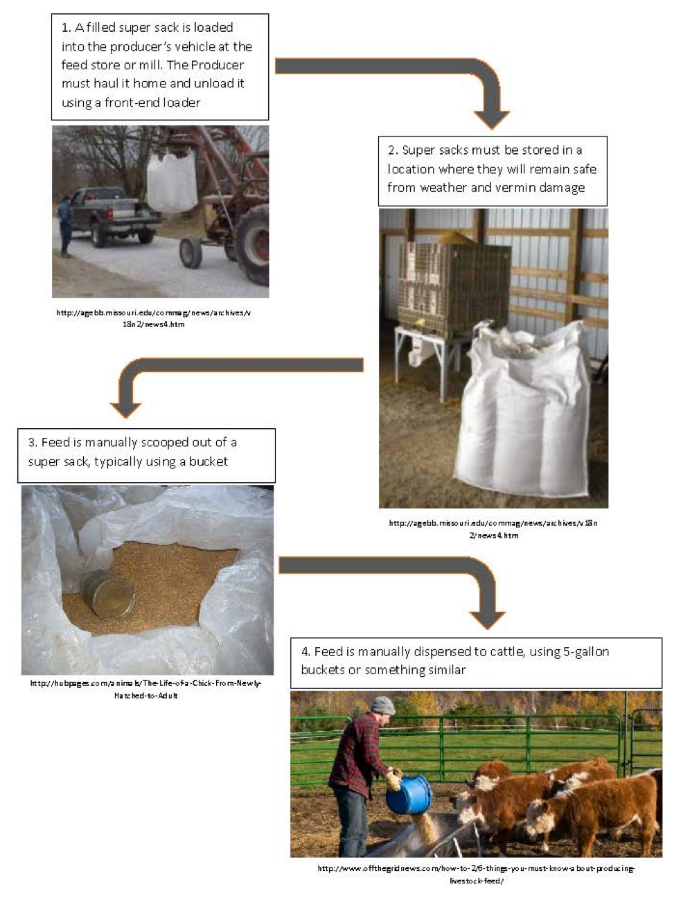

Super sacks (aka bulk bags, bulk totes, poly totes etc.)

Super sacks are another method that producers, as well as feed mills and stores, use to transport and store feed. Super sacks also often are called bulk bags, bulk totes or poly totes. Super sacks are bulk storage containers that are made from woven polypropylene. A super sack has four loops near the top of the sack, which allows it to be loaded and unloaded using a forklift or tractor with a front-end loader. A super sack is filled through an opening in the top of the sack, and producers normally scoop feed through this same opening before feeding. Some super sacks also have closeable flaps on the bottom of the sack, allowing producers to retrieve feed while the sack is suspended from a front-end loader or holding rack. Feeding is typically done with a bucket because the sacks are too heavy to lift and pour. Super sacks are available in various sizes, but most hold either 1,000 or 2,000 pounds.

SWOT Analysis of a Super Sack Feeding System

- Strengths

- Allows producers to take advantage of bulk feed prices without a large investment in feeding equipment.

- Super sacks can be reused.

- Less labor is required for loading and unloading compared to 50-pound bags, as long as adequate handling equipment is available.

- Weaknesses

- Susceptible to damage from weather and rodents.

- Require a tractor with a front-end loader or forklift to move.

- Not permanent and eventually must be replaced after a few uses.

- Manual labor is required to scoop feed out of a super sack.

- Dispensing feed to livestock is still a manual process, and safety risks can be associated with feeding amongst large, hungry animals.

- Opportunities

- Super sacks can be filled with substances other than feed.

- Potential to reach environmentally-conscious customers who see 50-pound bags as a waste of resources.

- Age of agricultural producers is increasing, meaning that producers who feed using 50-pound bags may be looking for alternative methods in the future.

- Threats

- Limited types of feeds sold in bulk quantities.

- Potential for increase in polypropylene manufacturing costs.

Gravity-Flow Feed Buggy

A feed buggy is an additional tool that can be used to transport, store and even dispense feed in some cases. This type of equipment allows a producer to take advantage of bulk feed prices without the need for a front-end loader or flatbed pickup, while keeping feed safe from rodent and weather damage. Feed buggies typically have a capacity of 1-2 tons and are built like a small trailer, allowing them to be towed behind a pickup or other vehicle. Gravity-flow feed buggies have a sliding gate in the bottom-rear of the bin that can be opened to allow feed to flow through without an auger or belt. Gravity-flow feed buggies are not typically used to dispense feed to livestock directly. Under normal operation, a producer would use the opening in the buggy’s bin to fill 5-gallon buckets and then use the buckets to feed livestock. Feed buggies are available from many small metal fabrication shops across the Midwestern U.S. that specialize in agricultural equipment.

SWOT Analysis of a Feeding System using a Gravity-Flow Feed Buggy

- Strengths

- 5-gallon buckets can be filled more easily with feed buggies than super sacks because the tapered shape of a feed buggy allows gravity to propel feed through the slide opening.

- Producers can use feed buggies to take advantage of bulk feed prices.

- Provides a safer way to store feed compared to bags or super sacks.

- Larger capacity than most other systems.

- Can be transported without the need for a tractor with a front-end loader or forklift.

- Weaknesses

- Dispensing feed to livestock must be done manually, leading to increased labor requirements and risks associated with feeding amongst large, hungry animals.

- Requires a relatively costly initial investment.

- Can be difficult to maneuver a small trailer around the bulk feed area of a feed mill.

- Opportunities

- Feed buggies can be towed behind a wide variety of vehicles, including cars, pickups and SUVs.

- Threats

- Just as expensive as pickup-mounted feeders but do not provide a method for automatically dispensing feed.

- Feed buggies with dispensing mechanisms will automatically dispense feed, making them a threat to gravity-flow feed buggies because of their labor savings.

- Require maintenance costs over time because tires are prone to wear and dry-rotting.

Figure 7. Flow chart for a feed buggy feeding technique.

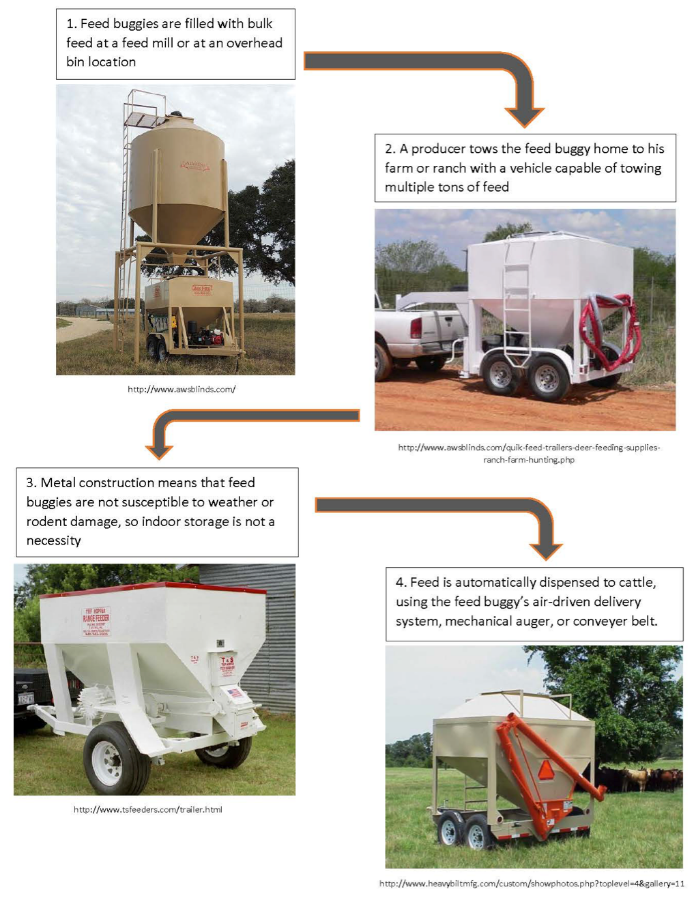

Powered Feed Buggy

Powered feed buggies are constructed similarly to gravity-flow feed buggies and also allow producers to take advantage of bulk feed prices without the need for a flatbed pickup or tractor with front-end loader. Powered feed buggies, however, provide a method for dispensing feed through the use of a mechanical auger, air-delivery system or conveyor belt. Powered feed buggies typically also have a larger capacity than gravity-flow feed buggies (2-10 tons) and consequently require a much larger initial investment.

SWOT Analysis of a Feeding System using a Feed Buggy with Auger

- Strengths

- Does not require the use of a front-end loader or flatbed pickup.

- Allows producers to take advantage of bulk feed prices.

- Capable of automatically dispensing feed to livestock.

- Provides a method of storage to keep feed dry and safe.

- Large capacity.

- Weaknesses

- Requires a larger initial investment than most other feeding systems.

- Tires are subject to wear and rotting.

- Can be tedious or difficult to maneuver a trailer around a confined space or to hookup/unhook a trailer frequently.

- Opportunities

- Can be towed by a variety of vehicles, leading to the potential to appeal to a wider market segment.

- Greater capacity can lead to fewer trips to obtain feed, which can lead to fuel savings.

- Threats

- High initial cost may deter many smaller producers.

- Regular maintenance is required to prevent tire failure and maintain lubrication.

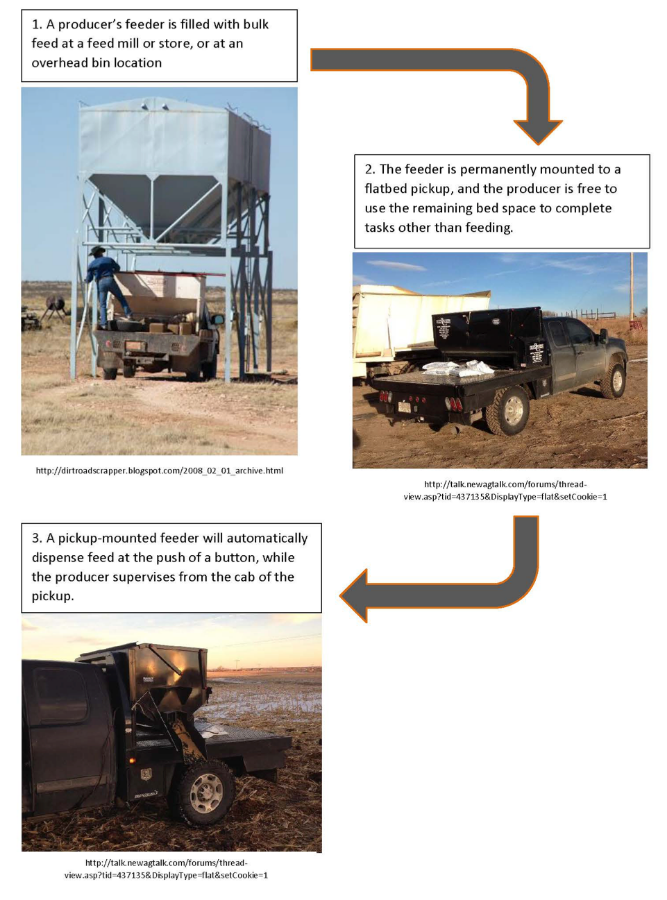

Pickup-Mounted Feeder

Pickup-mounted feeders are commonly referred to as “cube” or “cake” feeders. The majority of these feeders fall in the 1,000-2,000 pounds capacity range, even though pickup-mounted feeders with capacities as small as 750 pounds and as large as 3,000-plus pounds are available. Some manufacturers offer smaller models designed for use with ATVs and UTVs. Most pickup-mounted feeders use an electric motor, which is hard-wired to the pickup’s battery to power an auger or belt and is then used to dispense feed automatically at the push of a button. Some models offer digital counters to measure feed output more precisely. Because pickup-mounted feeders are wired to a pickup’s electrical systems, they are typically a permanent fixture upon a flatbed pickup.

SWOT Analysis of a Feeding System using a Pickup-Mounted Feeder

- Strengths

- No physical labor required to handle or dispense feed—this is done automatically by an electric motor hard-wired to the pickup.

- Prevents water and rodents from penetrating into feed.

- Some models have a large capacity of 2,000-3,000-plus pounds.

- Digital measuring devices available with some models.

- Weaknesses

- Dedicated feed/farm truck with flatbed required.

- Requires a more costly initial investment than many other systems.

- Feeder is permanently mounted to the pickup truck.

- Opportunities

- Producers can travel longer distances in less time using a pickup rather than a UTV or tractor, leading to potential efficiency increases.

- Capable of dispensing a wide variety of feedstuffs.

- Threats

- Most cattle producers have fewer than 50 cattle, and many small-scale producers do not have a dedicated feed/farm truck.

- Limited feeds available for bulk purchase.

- Trucks are less common on U.S. farms and ranches than tractors, according to the United States Department of Agriculture.

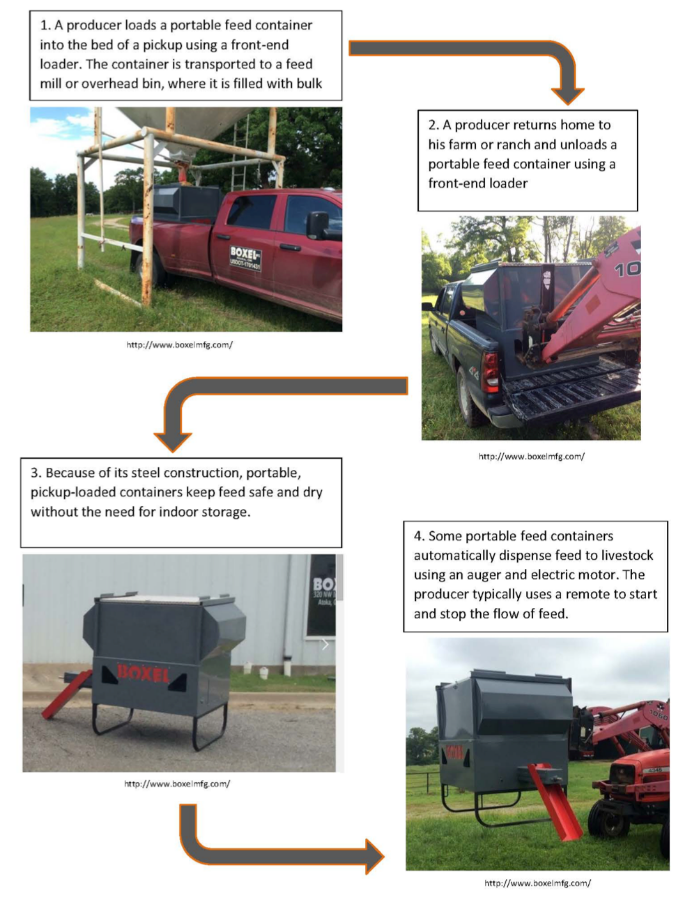

Portable, Pickup-Loaded Feed Container

Portable, pickup-loaded feed containers are designed to aid in the transportation, storage and dispensing of bulk feed. In general, this type of feeding equipment is comprised of a metal box, which may or may not contain an automatic dispensing mechanism like an auger. Most are intended to be handled using a tractor with front-end loader without the need to be permanently attached to any form of driving equipment. The containers typically have a capacity of 1,000-2,000 pounds, which likely allows them to be hauled in a vehicle as small as a ½-ton pickup. Some of these portable feeders use electric motors and augers to automatically dispense feed, which are actuated by a wireless remote. Feeding with a portable container can be accomplished using a tractor, pickup or even UTV depending on the container size.

SWOT Analysis of a Feeding System using a Portable, Pickup-loaded Feed Container

- Strengths

- Removable from vehicle.

- Designed to be used by a tractor with a front-end loader.

- Container is rodent-proof and weatherproof.

- Capable of automatically dispensing feed into bunks, troughs or directly on the ground with an auger and electric motor if applied.

- Weaknesses

- Requires a forklift or tractor with front-end loader to for handling.

- Requires a more costly initial investment than some other feeding equipment.

- Most do not contain the digital counting capability common with many pickup-mounted feeders.

- Opportunities

- Can store and dispense a wide variety of feedstuffs.

- Tractors are more common than trucks on U.S. farms and ranches, which may provide excellent growth potential.

- Ability to distribute through tractor dealer networks.

- Threats

- Limited brand presence for manufacturers of these products, while some competitors have established brands and dealer networks.

- Limited feeds available for bulk purchase.

References

Dhuyvetter, Kevin and Kevin Herbel. “Feed Costs: Pasture vs. Non-pasture Costs: An Analysis of 2012 Kansas Farm Management Association Cow-Calf Enterprise.” Kansas State University Department of Agricultural Economics (Publication: AM-KCD-2013.08.01). Aug. 2013. Web. Accessed 15 June 2015.

“Payback Period.” Investopedia.com. Web. Accessed 17 November 2015.

“Net Present Value-NPV.” Investopedia.com. Web. Accessed 17 November 2015.

“Internal Rate of Return.” Investopedia.com. Web. Accessed 17 November 2015.

Dillon Rapp

Graduate Research Assistant

Dan Tilley

Professor Emeritus

Rodney Holcomb

FAPC Agribusiness Economist