Ammoniation of Low Quality Roughages

Each year, an abundance of low quality roughages is produced in Oklahoma. The supply of low quality roughages is the result of many factors including: high precipitation during the haying season, late harvest dates, and drought. Crop residues, such as wheat straw, grain sorghum stover, and corn stover are other potential sources of low quality roughages that are not often utilized in beef cattle diets because of their low nutrient value. Still another source of low quality roughage has resulted from CRP (Conservation Reserve Program) land that is either coming out of the CRP program or haying that has been allowed to relieve drought situations.

Application of anhydrous ammonia provides an opportunity to substantially improve the nutrient characteristics of these roughages. Use of this technology has grown considerably in the past 15 years. In general, a stack of roughage is covered with a polyethylene sheet to create an air and ammonia tight seal. Anhydrous ammonia is injected into the stack and allowed to react with the roughage for one to four weeks.

Why Ammoniate?

When an abundance of moderate to high quality forage is available, there is little reason to consider ammoniation. Application of this technique will be most practical in years of drought, when little forage is available or when moderate to high quality forage is expensive. It is also beneficial in situations when there is some other incentive to bale low quality roughage. An example of this includes operations where the main objective is to grow a fescue seed crop. The fescue residue is often baled to remove the material from the soil surface in order to allow forage re-growth to occur. The ammoniation process serves to convert the residue by-product into a moderate quality roughage for cattle.

Ammoniation improves roughage nutritive value by:

- Increasing roughage digestibility

- Increasing roughage intake

- Increasing crude protein content

- Allowing storage of higher moisture roughage by inhibiting mold development

Crude Protein

An Oklahoma study (Zorrilla-Rios et al., 1991) addressed the use of ammoniated wheat straw in emergency feeding programs for growing cattle. The wheat straw used in the study had initial crude protein and digestibility contents of 3.6 and 26% respectively. Steer calves (635 lb. initial weight) were fed untreated or ammoniated wheat straw and about 6.5 lbs. of corn. Increased amounts of soybean meal up to 1.23 lbs./day were fed with untreated straw; whereas, steers fed ammoniated straw did not receive any supplemental protein. Daily live weight gain of steers fed untreated straw and the highest level of soybean meal or ammoniated straw and no supplemental protein was about 1.0 lb. The increased crude protein of ammoniated straw decreased the need for supplemental protein by an amount equivalent to 1.25 lbs. of soybean meal/steer/day. This is often referred to as the protein-sparing effect of ammoniated roughages and is likely due to the increased intake of digestible dry matter (DM) and added crude protein of ammoniated roughages which increases microbial protein synthesis in the rumen.

Digestibility and Intake

Roughage digestibility and intake are enhanced beyond the improvements seen when a protein supplement is used to correct a protein deficiency in untreated roughage (Table 1). Replacing one pound of corn supplement with soybean meal resulted in a minimal improvement in weight gain (from 1.00 to 1.17 lbs./day) for steers receiving untreated hay. Ammoniation of the hay resulted in an average of 0.56 lb./day improvement in weight gain and an average of 21% greater hay intake. Similarly, gestating cows fed ammoniated wheat straw had a higher roughage intake and weight gain compared to cows fed wheat straw and supplemented with alfalfa hay as a protein source (Table 2).

Table 1. Effect of ammoniation of grass hay and supplementation on steer performancea

| Supplement(lb./day) Corn | Supplement (lb./day) Soybean Meal | Hay | Gain (lb./day) | Hay Intake (lb. DM/day) | |

|---|---|---|---|---|---|

| 0 | 0 | Untreated | 0.35 | 8.7 | |

| Ammoniated | 0.81 | 10.5 | |||

| 4 | 0 | Untreated | 1 | 8 | |

| Ammoniated | 1.56 | 9.5 | |||

| 3 | 1 | Untreated | 1.17 | 8 | |

| Ammoniated | 1.53 | 9.8 |

a Lechtenberg et al., Purdue University, 1980. Ninety day trial with 60 head of 500

lb. steers. Mature orchardgrass hay initially contained 7% CP and was 46% digestible.

Protein and digestibility after treatment was 14 and 54 percent, respectively.

Table 2. Performance of gestating cows in a dry-lot, fed untreated wheat straw and 7 lbs. of alfalfa or ammoniated strawa

| Straw + Alfalfa | Ammoniated Straw | ||

|---|---|---|---|

| Roughage intake, lb./day | 21.8 | 26.1 | |

| Cow weight change, lb./day | -0.27 | 0.1 |

a Ward et al., University of Nebraska, 1982.

Mold Inhibition

Mold and fungus cause heating and deterioration of hay and crop residue if roughage moisture content is above 20%. Ammonia, at a level of 1.5-2.0% of hay DM, acts as a fungicide and can effectively preserve roughages containing up to 30% moisture.

How does it work?

The term “anhydrous” in anhydrous ammonia refers to the absence of water. When the gaseous anhydrous ammonia comes in contact with roughage, it combines with the moisture (water) in the roughage to form ammonium hydroxide. Plant cell walls are made up of complex carbohydrates consisting of three primary compounds; cellulose, hemicellulose, and lignin. Ammonium hydroxide is an alkaline compound, much like lye soap, and serves to:

- solubilize hemicellulose by breaking chemical bonds holding lignin and hemicellulose together; and

- partially break down the structure of cellulose by disrupting hydrogen bonds.

This reaction causes a swelling of the fiber and allows cellulase (the enzyme responsible for cellulose digestion) better access to the fiber for digestion (Church, 1988). Following ammoniation, most roughages have a darker caramel-like color and a softer texture.

What roughages can be ammoniated?

Any roughage that has low nutritive value is a good candidate for ammoniation. Table 3 shows examples of different roughages that have been ammoniated and the resulting changes in crude protein content, dry matter digestibility, and roughage intake.

Table 3. Results of roughage ammoniation trialsa

| Roughage | % Crude Protein Untreated | % D.M. Digestibility Treated | % D.M. Digestibility Untreated | % D.M. Digestibility Treated | % D.M. Digestibility Increase In D.M. Intake |

|

|---|---|---|---|---|---|---|

| Wheat Straw | 3.7 | 9.7 | 38.9 | 48 | 0.18 | |

| Corn Stover | 6.2 | 11 | 48 | 56.2 | 0.22 | |

| Milo Stover | 5.4 | 16.8 | 46.2 | 61.3 | - | |

| Prairie Hay | 5.8 | 14.7 | 49.5 | 58.2 | - | |

| Fescue Hay | 6.6 | 14.8 | 39.7 | 57.7 | 0.36 | |

| Orchardgrass Hay | 7.1 | 14.2 | 46.1 | 54.3 | 0.22 | |

| Switchgrass Hay | 4.5 | 11 | 43.3 | 53.2 | 0.03 |

a Adapted with modifications from Kuhl, Kansas State University, 1981.

Important considerations

- Site selection. Select a site for the ammoniation stack that is relatively flat, but well drained. If possible, a location somewhat shielded from the wind is preferable.

- Bale size and stack size. Any size roughage package can be ammoniated including; loaves, loose stacks, round bales, and square bales of all sizes. Single or multiple tiers of bales can be used effectively. In the “stack method” the limiting factors to stack size are generally polyethylene sheet size and stacking equipment. Ammonia has exceptional penetrating qualities, allowing for large, tight stacks of hay to be treated.

- Moisture level. Roughages should contain a minimum of 10% moisture for the ammoniation process to be successful. Optimal moisture level is between 15 and 18%. Roughages with as high as 25 to 30% moisture have been successfully treated.

- Timing of treatment. For best results and most efficient use of purchased materials, hay should be ammoniated immediately after harvest. This will minimize loss from weathering and prevent ammonia “hot spots” due to ammonia concentrating in wet areas of the hay.

How to Ammoniate

1. Make certain there is a ready source of anhydrous ammonia available in your area. This can be a major limitation in areas where there is little farming.

2. In order to apply the appropriate amount of ammonia, it is important to make an accurate determination of roughage weight. Weigh at least five large bales (20 small bales) in order to get a good indication of average weight. Remember different types of roughages often have very different densities and bale weights. Also, estimate roughage moisture content because the amount of anhydrous ammonia applied is based on dry matter (DM). For example, 10% moisture content wheat straw has 90% DM which equates to 1800 lbs. of DM per ton of straw (2000 X .90).

3. Calculate the amount of anhydrous ammonia to be applied. Research has shown that between 2% and 3% ammonia on a roughage DM basis (60 lbs. per ton of DM) provides good results. Also consider how to regulate the total amount of ammonia applied. One option is to prepare the stack, calculate the total amount needed, and then place an order for a tank that contains no more than the amount needed. Application can also be monitored with ammonia regulators to aid in accurate application. Another alternative is to use the percentage gauge on the anhydrous ammonia tank to estimate the amount of ammonia that has been injected. For example, if capacity of an anhydrous tank is 5000 lbs., one percentage point on the tank gauge is 50 lbs. (5000 x 0.01). If the goal is to apply 1500 lbs., the percentage units change on the tank gage would be:

1500 lbs. ÷ 50 lbs. per percentage unit

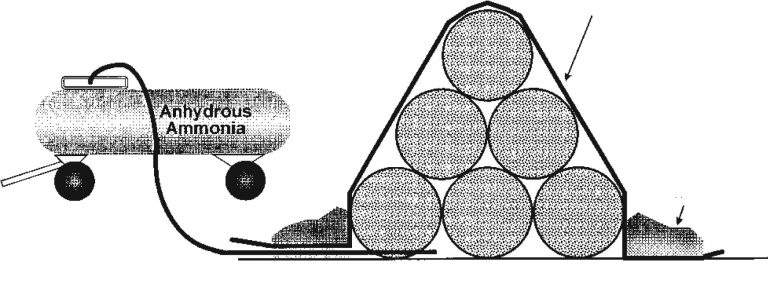

4. Arrange bales so that a single sheet of polyethylene (usually 40 X 100 ft.) can cover the entire stack with at least 2 ft. of surplus sheeting along all edges so the stack can be sealed. For large round bales, a pyramid three bales high with three forming the base or two bales high with four forming the base works well depending on bale size. It is not necessary to place polyethylene between the ground and hay because minimal ammonia will be lost through the ground during application and storage.

5. The ammonia can be applied through a hose or pipe extending from the tank under the plastic and terminating near the center of the stack. Placement of the end of the hose or pipe is not critical. Ammonia has excellent dispersion qualities and will rapidly penetrate all areas of the stack. If the hay is stacked on a slope, the ammonia should be injected at the higher end of the stack.

6. Cover the stack with a single sheet of polyethylene (6-mil or 8-mil thickness). Black polyethylene is recommended because it is more resistant to ultraviolet light deterioration than other colors. Be careful not to tear the polyethylene while covering the stack. All holes and tears must be repaired to prevent the loss of ammonia. To make the stack air tight, seal all edges of the polyethylene using at least eight inches of soil, fine rock or other weighty material. In addition to creating an air-tight seal, the soil around the base will also help to anchor the sheeting to prevent possible wind damage.

7. Apply ammonia slowly (no more than 30 lbs. of ammonia per minute). Slow application will minimize ballooning and stretching of the polyethylene sheet. Anhydrous ammonia expands from a liquid to a gas when it is released from pressure. The warmer the temperature, the more the gas will expand. Applying the ammonia during late evening and night hours, especially during mid-summer, will minimize ballooning and stretching of the polyethylene.

Figure 1. Using anhydrous ammonia with the sheeting covering hay.

8. The length of time required for the stack to remain sealed depends on the environmental temperature as shown below:

Temperature (°F) Weeks of treatment

Below 40 More than 8

40 to 60 4 to 8

60 to 80 2 to 4

Above 80 2

Keep hay covered until a few days prior to feeding. Ammoniated hay takes on moisture more readily and is more susceptible to spoilage than untreated hay because the fiber has been partially broken down. Uncovering the stack two days prior to feeding will allow any excess ammonia to escape.

Precautions

Ammoniation of moderate and high quality forages can cause toxicity in cattle!

Restrict ammoniation to mature, low quality roughages. Ammoniation of high quality

roughages, such as alfalfa, forage sorghum, hybrid sudan, small grain hays, or any

moderate to early harvested grass hay (including both cool and warm season species),

can lead to toxicity problems known as “crazy cow syndrome” or “bovine bonkers.” Symptoms

include hyperexcitability, circling, convulsions, and even death.

Toxicity is caused when cattle consume sufficient quantities of the toxic compound,

4-methylimidazole, which is formed when soluble sugars in the roughage react with

ammonia. This compound passes through the milk to affect nursing calves, and in fact,

nursing calves seem to be more susceptible to the toxicity than mature animals. Mature

roughages have low soluble sugar content and represent little risk of toxicity problems.

To minimize the risk of toxicity:

- Do not ammoniate moderate or high quality forages

- Do not apply more than 4% ammonia on a dry matter basis

- Do not ammoniate roughage that has wet spots from recent heavy rains because ammonia will concentrate in these wet spots

To reduce the risk of calf toxicity, either refrain from feeding ammoniated roughage to cows with young calves or wait until the calves are at least one month old.

If toxicity does occur, immediately remove ammoniated roughages for several days and avoid working or exciting the cattle.

Exercise Extreme Caution When Applying

Anhydrous Ammonia

Exposure to anhydrous ammonia can cause blindness, lung damage, burns, or death. If you are exposed, immediately flush the exposed area with water for at least 15 minutes. Seek medical attention immediately after emergency first aid treatment.

To be safe using anhydrous ammonia, always:

- Wear personal protective equipment including a mask, goggles, gloves, long-sleeved shirt, long pants, and proper work shoes.

- Have an ample water supply close by.

- Regularly inspect hoses and valves and replace them as needed.

- Be careful not to fill a tank over 85 percent of capacity.

- Bleed off hose pressure before disconnecting.

- Stay clear of hose and valve openings.

- Stay clear of hose and valve openings.

- Have a qualified technician repair the tank.

- Use the proper hitch, safety chains, and a Slow Moving Vehicle sign when towing.

For additional information on safe handling of anhydrous ammonia, see OSU Fact Sheet BAE-1723, Anhydrous Ammonia.

What Does Ammoniation Cost?

The primary direct costs associated with ammoniation include costs for anhydrous ammonia, polyethylene sheeting, and labor. Table 4 gives an example of these costs.

Ammoniation generally costs $20 to $30 per ton of roughage. Larger stacks are cheaper to ammoniate per ton because labor, plastic, and miscellaneous costs are spread over more total pounds of roughage.

Table 4. Ammoniation costs for 105 round bales of mature prairie hay.a

| Item | Units | Cost/Unit | Total Cost | Cost/Ton of Roughage | |

|---|---|---|---|---|---|

| Anhydrous ammonia | 2,310 lbb | $0.33/lb | 762.3 | 14.52 | |

| 6 mil polyethylene sheeting (40’ x 100’) | 1 | 263 | 263 | 5.01 | |

| Crushed rock for plastic seal | 5 ton | 10 | 50 | 0.95 | |

| Labor | 12 man hours | 10 | 120 | 2.29 | |

| Miscellaneous equipment | 50 | 50 | 0.95 | ||

| Fuel (for stacking hay) | 10 gallons | 3.36 | 33.6 | 0.64 | |

| Total | 1278.9 | 24.36 |

a Average bale weight = 1,000 lbs. Dry matter content = 88%.

b 105 x 1,000 = 105,000 lbs. of roughage x 88% dry matter = 66,000 lbs. of dry roughage

x 3% = 1,980 lbs.

Supplementing Ammoniated Roughages

Because many low quality roughages contain extremely low protein (less than 5%), and all of the added ammonia nitrogen from the ammoniation process is not available to the animal, additional natural protein supplementation may be needed to increase animal performance (Zorrilla-Rios et al., 1991; Beck et al., 1992). As a rule of thumb, consider the added crude protein only 50% available to the animal. For example, average protein content of wheat straw was 3.7% before ammoniation and 9.7% after ammoniation for several trials (Table 3.) Therefore, the added crude protein is 6% and the added usable protein is 3% (6% x .5). Usable crude protein should be considered to be 6.7% (3.7% + 3%). If the calculated usable crude protein content is above the animal’s requirement, additional protein supplementation would not be warranted.

In situations where greater than maintenance performance is desired (such as in the case of thin, gestating cows), additional energy supplementation may be warranted. Grain based energy supplements have been shown to increase weight gain of gestating beef cows and growing steers receiving ammoniated roughages (Lechtenberg et al., 1980; Zorrilla-Rios et al., 1991; Beck et al., 1992; Fike et al., 1995).

What is the Value?

The value realized from ammoniating roughages of low nutritive value will depend on:

- availability and/or cost of alternative roughages

- improvement in nutritional value

- cost of supplementing untreated hay

- the value of any improvement in animal performance compared to feeding untreated hay

Table 5 shows an example of 90-day feed costs for gestating cows consuming low quality native grass hay and a protein supplement with variable supplement prices. To determine the value of the ammoniation process in this example, simply subtract the 90-day feed cost of hay and range cubes from the 90-day feed cost of ammoniated hay. In this example, the ammoniated roughage does not require supplementation. Consequently, further savings should be realized from less fuel, labor and equipment use with the ammoniated hay.

Table 5. Value of ammoniating mature prairie hay for gestating cows.

| Wintering Programa | 90 Day Feed Cost | |

|---|---|---|

| Ammoniated hay | 134.1 | |

| Hayb + range cubes @ $350/ton | 161.1 | |

| Hay + range cubes @ $375/ton | 164.7 | |

| Hay + range cubes @ $400/ton | 169.2 | |

| Hay + range cubes @ $425/ton | 172.8 | |

| Hay + range cubes @ $450/ton | 176.4 |

a Ammoniated hay alone or untreated hay plus 3.5 lbs. of 25% protein range cubes. Calculated

to meet nutrient requirements of 1,200 lb. cow during last 90 days of gestation. Assumes

restricting ammoniated hay intake to 24 lbs, which should result in approximately

equal cow weight change when cows consuming untreated hay have free choice access.

b Mature prairie hay valued at $100 per ton. Assumes untreated hay contains 5.5% protein,

54% TDN and ammoniated hay contains 12% protein and 58% TDN. No supplementation is

required for the ammoniated hay.

Summary

Ammoniation presents an opportunity to transform a product of little value into a valuable feed resource. Certainly, planning and good management are required to make this procedure successful, but the economic rewards can be significant.

References

Church, D.C. 1988. The Ruminant Animal. Prentice-Hall, Englewood Cliffs, NJ.

Fike, G.D. et al. 1993. Protein Supplementation of Ammoniated Wheat Straw: Effect on Performance of Beef Cows. Cattleman’s Day Report of Progress Kansas State University 678:113.

Kuhl, Gerry L. 1981. Ammoniation of Dry Roughages for Beef Cattle. 7th Annual O-K Beef Cattle Conference Proceedings. Kansas State University.

Lechtenberg, V.L. et al. 1980. Animal Gains on Ammoniated Hay. Indiana Beef Cattle Day Proceedings, Purdue University.

Ward, J.K. et al. 1982. Ammonia Treatment of Wheat Straw. Beef Cattle Report, University of Nebraska MP43:12.

Zorrilla-Rios, J. et al. 1991. Energy and Protein Supplementation of Ammoniated Wheat Straw Diets for Growing Steers. J. Anim. Sci. 69:1809-1819.

David Lalman

Extension Beef Cattle Specialist

Gerald Horn

Professor Animal Science

Ray Huhnke

Extension Agricultural Engineer

Dillon Sparks

Graduate Research Assistant