Agricultural Pesticide Storage

Using pesticides requires detailed attention to label instructions as well as common

sense and good judgment. These same factors apply to pesticide storage. Using improper

storage procedures is an open invitation for a disaster to happen. Some agricultural

pesticides are more toxic and formulated in higher concentrations than the products

homeowners or home gardeners are used to using; so keeping unqualified, inexperienced

people out of the storage area is important.

Nearly three-fourths of all pesticide accidents are non-use accidents—often involving

children under 10 years of age. In addition there have been cases of livestock losses

in several states when pesticides accidentally contaminated feed. The economic loss

in just one of these instances amounted to several thousand dollars. A farmer or commercial

applicator may have a large sum of money invested in a pesticide inventory. A secure

storage area can protect that investment from theft and the elements.

Besides safety and economics, improper storage of pesticides is contrary to federal and state regulations governing pesticide use. You could be cited or fined for improper pesticide storage particularly if an accident happens as a result of the improper storage. Instructions for storing and disposing of pesticide containers are usually found on the product label. Always read and follow these directions carefully. The following information in this fact sheet is not intended to supersede any manufacturer’s specific instructions.

Site Selection

Whether you are choosing a site to build a new storage area, or are using existing

buildings, several points need to be considered in selecting the site. One of the

factors is prevailing wind direction. The site should be located down-wind and downhill

from sensitive areas, such as houses, play areas, feedlots or animal shelters, gardens,

and ponds. Locating storage facilities away from human and livestock habitations will

avoid or minimize contamination in case of fire.

A drainage system should be built to collect any runoff water. Dikes, collecting pools, and washing slabs with sumps provide a proper drainage system. All the collected runoff water should be treated as surplus pesticide and disposed of properly.

Storage Area

The volumes and types of pesticides used will dictate the size of the storage facility

you need. A separate building may be needed if a large inventory is maintained. The

types of containers should also be considered. Besides the size and quantity of containers,

several basic needs apply to all pesticide storage areas. It must be able to be securely

locked and should be identified with warning signs. Ventilation and temperature control

are important as well as the choice of building materials in the consideration of

spill clean up, fire hazard, and future use requirements.

Metal buildings are better than frame construction because of reduced fire hazard and easier spill clean up. A concrete floor with a smooth finish is more desirable than a wood floor, because it can be decontaminated and resists chemical action. A concrete floor can be built with curbs for spill containment and can be sloped to a floor drain.

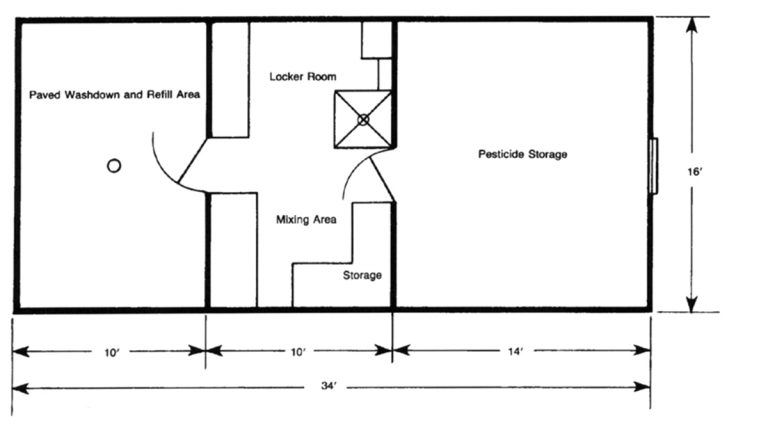

The floor plan in Figure 1 is a pesticide storage and mixing building with a concrete wash down and refill area. It is from Midwest Plan Service, Iowa State University, Ames, Iowa 50011. It is complete with shower, toilet, and lockers for safety equipment in addition to the storage area, mixing area, and the equipment wash down area.

Figure 1. Pesticide Storage and Mixing Building.

When the inventory is not large enough to warrant a new or separate facility, a building designed for other uses can be used. If the building does not have the proper specifications for pesticide storage, changes should be made to increase safety. These changes include: adding or repairing a door so the building can be locked; posting weatherproof warning or identification signs; and installing fans for ventilation. A water source, fire extinguisher, smoke alarms, and spill clean up equipment will upgrade the safety of the storage.

Several items are recommended to increase safety and utility of the storage area whether it is a new or existing structure. The storage area must be child proof. A fence that cannot be climbed with locked gate should surround the storage building to prevent unauthorized entry. Identification signs visible from any approach to the building should be on the fence, on the building, and at each gate, door, or window. Sign legible at least 50 feet stating “Caution – Hazardous Pesticide Storage Area Unauthorized Persons Keep Out” identify the area for the public and also for firefighters.

Regardless of its size, use a pesticide storage area only for pesticide and pesticide equipment. Never store pesticides with food, seed, fertilizers, veterinary supplies, or other stored products. The potential risk of contamination of these items by pesticides is too great.

Several instances of pesticide poisoning in livestock have been due to contamination of feed stored with pesticides or mistaking a sack of insecticide granules for a sack of feed for livestock. In one such instance in another state over 300 head of cattle died. Separate storage areas for feed and pesticides will greatly reduce the chance of this occurring.

Total decontamination of a pesticide storage facility is virtually impossible. Therefore, it should not be used subsequently as a storage site for other materials or as an animal shelter.

Use an electrically shielded exhaust fan for ventilation to reduce the temperature and high concentrations of toxic fumes. Locate the fan so the exhaust will not damage plants or harm people or animals. Odors or fumes tend to be more prevalent with dry formulations, especially if a bag has been opened or broken. Odors are more easily controlled with liquids in well-sealed containers, but can also occur if containers are broken. Storing granules in a separate area, if feasible, might help to reduce odors.

Some pesticides require protection against freezing or extreme heat and have suitable warnings on the label. At low temperatures, some chemicals may crystallize. If crystals have formed, the crystals may sometimes be brought back into solution by warming and agitation. Containers may be agitated by placing on their side and rolling occasionally. Although you may be successful in bringing crystallized chemicals back into solution, it is best to prevent freezing. Check the labels for storage temperatures.

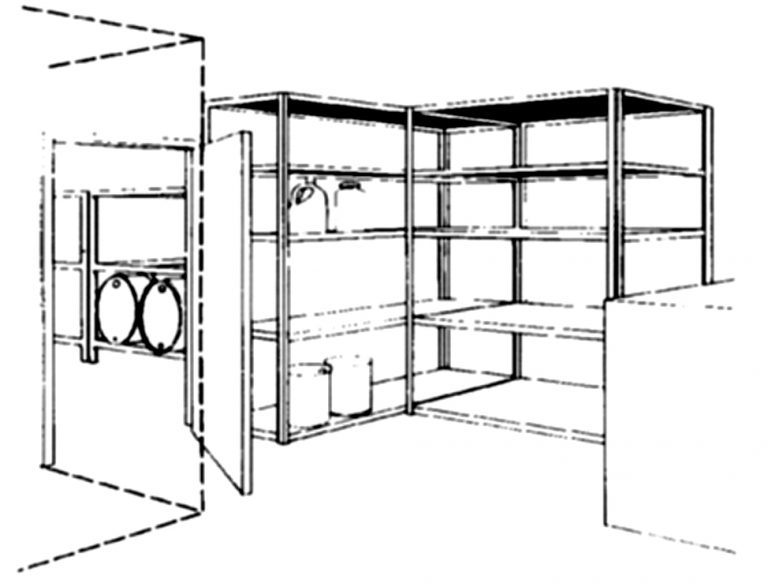

Sacks, cartons, and fiber boxes should be stored on pallets or on shelves off the floor (Figure 2). If metal pesticide containers are to be stored for a prolonged period, they should be placed on pallets to help reduce potential corrosion and leakage. Metal racks and shelving are easier to decontaminate than those made with wood.

Figure 2. Store Containers on Shelves

Glass, metal, and plastic containers of liquid pesticides should be stored where they

are not in the sun or near other sources of heat such as steam pipes. Heat will cause

the liquid to expand so that the contents will be under pressure. When the container

is opened, the pesticide may splatter on the applicator. No pesticides should be allowed

to become overheated. Some formulations will catch fire if they get too hot; others

lose their strength and break down when they are exposed to heat.

Procedural Precautions

Operating procedures used by an applicator in storing pesticides can help prevent many mishaps. Some of these procedures are required by law.

As soon as pesticides are delivered, they should be properly stored and the area immediately locked so that children and other untrained people cannot get to them. The pesticides should be removed from the storage area only for application or return to a dealer or manufacturer.

Leaving any pesticide unattended—however briefly—in other than a secure storage area is a careless and potentially disastrous practice. A locked storage area can help prevent theft of pesticides. If security is of concern to you, have a locksmith or responsible law enforcement officer review your locks and make suggestions for improvement.

Develop a marking system for the pesticides in storage. Manufacturer’s lot numbers are not adequate. Have your own identification code.

Store herbicides, insecticides, fungicides, etc. in separate locations within the storage area to prevent chemical contamination and accidentally using the wrong pesticide. In addition, all highly toxic pesticides within a particular group, such as insecticides or herbicides, should be stored together in a special area so that an applicator working in that area can take special precautions to keep from being exposed. Treated baits, such as rodenticides and avicides, should not be stored near other chemicals as they will pick up offensive odors, rendering them useless.

Store pesticides ONLY in the original container with the label plainly visible (Figure 3). Pesticides should NEVER be stored in anything used as a food or drink container even for a short time. Pesticides stored in a soft drink bottle, fruit jar, milk carton, etc. are a common cause of accidental poisoning. People may ask for a small amount of the pesticide that you are using, but unless you have a small package with the manufacturer’s entire label on it, you should not give anyone a pesticide.

Figure 3. Store pesticides with label plainly visible.

Furthermore, it is illegal to distribute or make available a RESTRICTED USE pesticide to anyone unless the person is certified or working under the direct supervision of someone who is.

All pesticide containers should be checked often for corrosion, leaks, and loose caps or bungs. These dangerous conditions must be corrected immediately. You may be able to position or rotate a can or drum that has been punctured to put the hole on top to stop the content from escaping, or you should put the pesticide in a sturdy container that can be sealed.

Label the new container immediately. Sometimes you can take the label from the damaged container and fasten it to the new container. Unlabeled pesticides are worthless and dangerous, since the applicator does not know what they are or how to use them. They should be treated as surplus pesticides held for disposal.

A special area should be used for surplus pesticides and their containers while they are being held for disposal. Label these pesticides plainly, and group them according to how you plan to dispose of them. These precautions will help prevent mixups resulting in improper disposal and accidental reuse.

If large quantities of pesticides are normally stored, the local fire department should

be informed. They should be given information on the location of the storage area

and the amount and types of pesticides normally present in the storage area.

Pesticide Storage Life

Shelf or storage life of pesticides is difficult to predict and is dependent on storage conditions. Most chemical manufacturers recommend storing pesticides no longer than two years. Most companies will not guarantee their products any longer than that. A few labels will indicate the storage life of the pesticide once the container is opened, but most do not.

Some pesticides lose active ingredients due to chemical decomposition or volatilization. Under conditions of high temperature and humidity, dry formulations can become caked and compacted and emulsifiable concentrates no longer form emulsions. The containers of pesticides stored for long periods may eventually corrode, crack, break, tear, or fail to seal properly.

Pesticide formulations that contain low concentrations of active ingredients generally lose effectiveness faster than more concentrated forms. Some liquid pesticides may form a gas as they deteriorate and this can make opening and handling containers quite hazardous. In time, the gas pressure may cause the container to rupture.

Certain pesticides have a characteristic odor. If the odor grows stronger in the storage area, it could mean a leak or spill, a defective closure, or an improperly sealed container. It may be a clue that the pesticide is deteriorating.

Fewer problems will occur with stored pesticides and the products will have a longer shelf life if the storage area is cool, dry, and out of direct sunlight. Protection from temperature extremes is important because either condition can shorten the shelf life of pesticides.

To reduce the problem of having old or ineffective pesticides, try to purchase only the amount of pesticide needed for the season. If possible return unused, unopened containers to the dealer. If circumstances make it necessary to maintain a larger inventory, be sure to rotate the stock. Older pesticides should be used first. To facilitate the “first bought, first used” policy, pesticide containers should be tagged or marked upon delivery with the date of purchase.

Handling Spills

In spite of all safety precautions, accidents will happen. If a pesticide spills in the storage area, quick action must be taken.

If someone is contaminated as a result of the spill, remove any contaminated clothing immediately and wash affected areas of the body with detergent and water. See a doctor if necessary.

If the spill is liquid, scatter activated charcoal, absorptive clay, vermiculite, pet littler, sawdust, or sweeping compound over the entire spill. Use enough to soak up most of the liquid. Then sweep or shovel it into a drum. Repeat using more absorptive material, until the spilled material is removed.

If the spill is dust, granular, or powder, then sweep or shovel it in to a leak proof drum. (Absorbent materials are not useful for dry spills).

Use a decontamination solution recommended by the manufacturer of the product. Materials commonly used are hydrated lime, lye, ammonia, sodium hypochlorite (laundry bleach), or detergent. Do not mix ammonia with laundry bleach, it is dangerous. A supply of these materials should be kept on hand in the storage area.

Always wear protective clothing including eye and lung protection, when cleaning a spill or using a decontamination solution. Dispose of cleaning equipment that cannot be decontaminated. Rinse the area with clean water and dispose of the contaminated absorbent, equipment, and decontamination solution in a specially designated landfill.

All uncontained spills of more than ten (10) gallons liquid or twenty-five (25) pounds dry weight of pesticide concentrate or fifty (50) gallons of an application mixture (tank mix) shall be reported within 24 hours by telephone and by written notice within three (3) days to Oklahoma Department of Environmental Quality, 405-702-5100 or 800-522-0206, P.O. Box 1677, Oklahoma City, Oklahoma 73101-1677 and Pesticide Section, Oklahoma Department of Agriculture, Food and Forestry 405-521-3864, P.O. Box 528804, Oklahoma City, Oklahoma 73152-8804.

If the spill is large or you are not certain how to handle the cleanup, telephone either CHEMTREC (Chemical Transportation Emergency Center) or the chemical manufacturer for instructions. The CHEMTREC toll free telephone number is 1-800-424-9300.

CHEMTREC and the Pesticide Safety Team Network (PSTN) have combined their communications links to provide a more unified system to deal with chemical-related accidents.

CHEMTRAC, which is sponsored by the Manufacturing Chemists Association, is now the contact for both services and provides a direct round-the-clock link to PSTN Area Coordinators across the country.

The Pesticide Safety Team Network was organized to provide emergency assistance in the event of a pesticide spill or accident during transportation. The service is a cooperative voluntary program operated as a public service by the National Agricultural Chemicals Association and 14 member companies.

In the event of a major accident or spill during transportation or warehousing, the 24-hour answering service provided by CHEMTREC will relay requests for assistance to the coordinator in whose area the help is needed. The person requesting assistance will be contacted by the PSTN Coordinator in a matter of minutes. At that time he will be instructed in immediate measures to take and a decision will be made whether a Safety Team should be sent to the scene.

More Information

For more information related to this subject call, write, or visit your OSU Extension Office and ask for:

EPP-7450 Pesticides Can Be Used Safely

Charles Luper

Extension Associate

Kevin Shelton

Extension Pesticide Coordinator