Cow-Calf Corner | May 5, 2025

Heifer Retention Prospects Improve

Derrell S. Peel, Oklahoma State University Extension Livestock Marketing Specialist

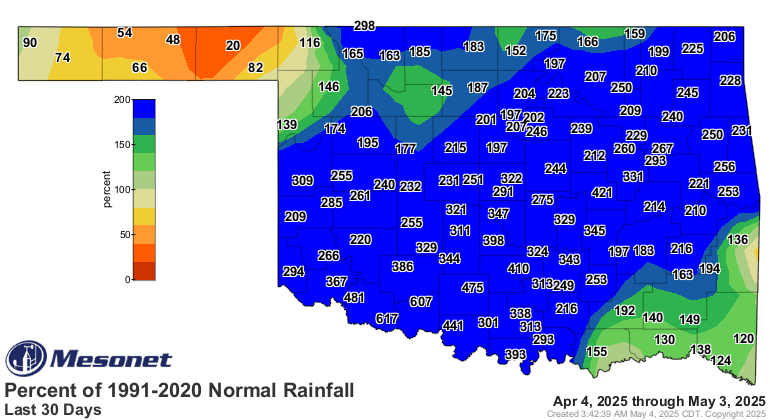

Much of the Southern Plains received significant precipitation in April, providing a much-improved pasture, hay and pond water situation. In Oklahoma, five of nine climate divisions had either the first or second wettest period on record from April 4 – May 3, resulting in the second wettest period statewide. Figure 1 shows that, for the 30 days ending May 3, all of the state, with the exception of the three panhandle counties, received over 100 percent to over 600 percent of normal precipitation.

Figure 1. Oklahoma Mesonet, Percent of Normal Rainfall. Last 30 Days - April 4, 2025 through May 3, 2025.

The immediate drought threat has been greatly reduced and has sparked more talk of heifer retention among producers and lenders. The April Cattle on Feed report showed that the number of heifers in feedlots had dropped and it appears that it will likely continue to drop in the coming months. The next quarterly check of heifers on feed will be in July, when a mid-year Cattle inventory report will also be available.

Increased heifer retention in 2025 can have two components. One form of heifer retention is unplanned (impulse) breeding of yearling heifers that were not noted as replacement heifers in the January 1 inventory. These heifers would have been counted as part of “other heifers”. Historical data shows that an average of roughly 13 percent of other heifers is typically bred each year as part of the total bred beef heifer supply the following January. During the last herd expansion from 2014-2019, this percentage increased to over 18 percent, meaning that an additional 300-400 thousand head of heifers were diverted from the feeder supply to breeding for the cow herd. A slower pace is expected in 2025, but impulse heifers breeding is likely to increase this year.

Additionally, beef producers may increase retention of heifer calves in 2025. These would be generally available to breed in 2026 and enter the cow herd in 2027. Fall-born heifers that will be weaned in the next couple of months could be bred in late 2025 and calve in the fall of 2026. Both of these factors suggest that the Cattle report next January could show an increase in beef replacement heifers, consisting of more bred heifers to calve in 2026 and more heifer calves to be bred in 2026. Heifer retention may be starting but the pace appears to be relatively slow. Certainly much slower than the last herd expansion a decade ago.

If heifer retention is accelerating, the most immediate impact will be reduced feeder cattle supplies available for placement in feedlots. I would expect to see feedlot inventories declining more noticeably in the coming months. With a lag of five or six months, heifer slaughter may decrease more noticeably. The next few months may show the long-awaited evidence of heifer retention.

Derrell Peel, OSU Extension livestock marketing specialist, says cattle markets remain strong, and recent rainfall is a factor, though trade uncertainty could lead to volatility on SunUpTV from May 3,2025.

Needle Selection for Vaccinating Cattle

Mark Z. Johnson, Oklahoma State University Extension Beef Cattle Breeding Specialist

When selecting a needle, choose one that is sharp, durable and detectable. It should be standard practice to avoid contaminated, burred, bent or broken needles. To help combat the chances of a needle breaking, use a durable, specialized stainless-steel needle with a thick-walled cannula. Change needles as frequently as necessary to guarantee needles remain sharp. If you are managing any blood-borne pathogens in your herd, such as anaplasmosis or bovine leukosis, it is necessary to replace the needle after each animal. Detectable needles offer the benefit of being easily identified and found by the metal detection systems within beef processing plants. The only 100% detectable needle is made of a specialized, highly ferritic, stainless-steel alloy.

Read product labels to determine the appropriate route of administration, whether it is subcutaneous (sub-Q) or intramuscular (IM). Next, determine the weight of the animal, not only for proper dosage, but also for selection of the appropriate needle. The route of administration determines the length of the needle, while the size of the animal determines the gauge, or diameter, of the needle. Viscosity of the product is another factor in the selection of the proper gauge. Lighter calves require a smaller-diameter needle, whereas heavier animals require a larger-diameter needle. It is important to note that as the gauge increases, the diameter decreases. There can be implications to selecting the wrong needle. It is critically important to use a needle of the correct length to ensure it enters the correct tissue. When this fails absorption of the product can be altered, resulting in failed efficacy. Furthermore, when treating young, light weight calves, if the needle is too long, there is potential to strike a bone or a nerve.

The chart below can help in deciding the needle gauge and length required.

| Injectable Viscosity | < 300 Cattle Weight | 300-700 Cattle Weight | > 700 Cattle Weight |

|---|---|---|---|

| Thin Example: Most Vaccines |

18 gauge | 18-16 gauge | 16 gauge |

| Thick Example: Thick antibodies |

18-16 gauge | 18-16 gauge | 16 gauge |

| Injectable Viscosity | < 300 Cattle Weight | 300-700 Cattle Weight | > 700 Cattle Weight |

|---|---|---|---|

| Thin Example: Most Vaccines |

18-16 gauge | 18-16 gauge | 16-14 gauge |

| Thick Example: Thick antibodies |

18-16 gauge | 18-16 gauge | 16-14 gauge |

| Injectable Viscosity | < 300 Cattle Weight | 300-700 Cattle Weight | > 700 Cattle Weight |

|---|---|---|---|

| Thin Example: Most Vaccines |

20-18 gauge | 18-16 gauge | 18-16 gauge |

| Thick Example: Thick antibodies |

18-16 gauge | 18-16 gauge | 16 gauge |

Select the needle based on cattle size (use the smallest without bending).

The smaller the gauge number, the larger the needle diameter. For example, a 16 gauge is larger than an 18 gauge.

Reference: Cattle Vaccination Needle Selection

Dr. Rosslyn Biggs, DVM, OSU Extension beef cattle specialist, takes an in-depth look at handling and administering vaccines on SunUpTV from January 22, 2022.

Supplementing Dried Distillers Grains (DDGS) Cubes and Tubs to Stocker Calves Grazing Mixed Grass Prairie in Western Oklahoma

Paul Vining and Paul Beck, Oklahoma State University Cooperative Extension Service

Growing calves grazing rangeland pasture during the summer often lack sufficient nutrition to achieve desired body weight gains. Providing a nutritional supplement can help bridge nutrient gaps and enhance performance, but frequent deliveries of supplemental feed are becoming increasingly costly due to rising fuel and labor expenses. To explore a more cost-effective approach, Oklahoma State University Animal Science Researchers conducted a stocker calf supplementation study to compare self-fed to hand-feeding supplemental distillers grains at the Marvin Klemme Range Research Station in Bessie, Oklahoma.

The distillers grains-based supplements provided by Pellet Technologies USA (York, NE) were in two different forms:

- A dried distillers grains (DDGS) cube (PowerCubes™, Pellet Technologies LLC)

- A 200-pound DDGS pressed tub (PowerTubs™, Pellet Technologies LLC)

During the early summer period, steers fed tubs consumed approximately 2.2 pounds of feed per head each day. Adjustments were made in the late summer to ensure the target daily intake of 2.5 pounds for the groups fed tubs to more closely match targeted intake in hand-fed groups for the remainder of the trial. Steers fed cubes received approximately 2.5 pounds of feed per head each day throughout the entire study.

Calf Performance

There were no significant differences in starting, mid-point, or final body weights between the two feeding methods. Average daily weight gains were also similar during both the early and late grazing periods. However, over the full 140-day trial, steers that were hand-fed cubes gained slightly more weight (0.18 pounds per day) than those consuming the tubs. This slight improvement in daily weight gain for the cube-fed steers was likely due to a marginally greater amount of supplement consumed during the early grazing period.

Economic Considerations

While hand-feeding cubes three times per week resulted in slightly better weight gains, the additional costs associated with supplement delivery could outweigh these benefits. Using estimated feed costs of $0.26 per pound for DDGS cubes and $0.55 per pound for the tubs, a round-trip feeding route of approximately 54 miles would justify the higher expense of the tubs.

Future Data Analysis and Experiments

This study also collected data on pasture forage quality, including forage biomass and nutritional value, to better understand how grazing conditions influenced steer performance. Researchers plan to repeat this study at the same location during the summer of 2025, using the same DDGS products provided by Pellet Technology USA. Insights from the upcoming trial, along with the current data, will further refine the understanding of supplementation strategies and their economic feasibility.