Cow-Calf Corner | April 28, 2025

Regional Feeder Cattle Prices

Derrell S. Peel, Oklahoma State University Extension Livestock Marketing Specialist

Cow-calf production is widespread across the country. According to the Cattle report for January 1, 2025, the five largest beef cow states have 39.1 percent of the total beef cow herd but a total of 18 states have at least 2 percent of the total beef cow inventory. The majority of calves move to the middle of the country as stocker or feeder cattle and are assembled into larger groups, culminating in relatively concentrated feedlots. The top five cattle feeding states have 71.9 percent of total cattle on feed. Most feeder cattle change hands at least once to as many as four or five times by the time they are finished in the feedlot. Feeder cattle prices are the thread that connects and coordinates production and marketing between sectors that frequently have no contact beyond market transactions.

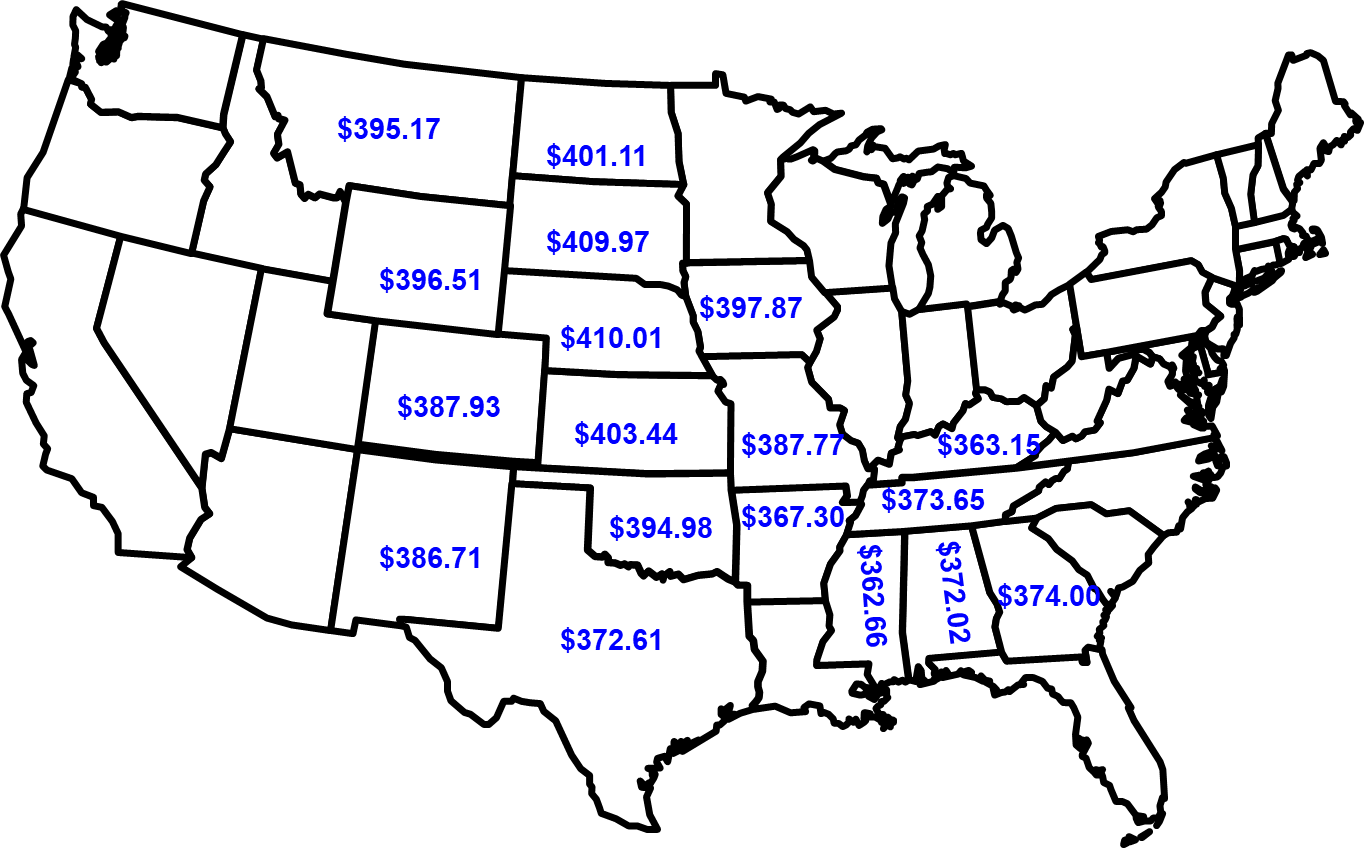

Feeder cattle prices around the country reflect local supply and demand conditions and the economic process of moving cattle to the middle of the country where feedlot production is concentrated. Figure 1 shows the average price of 500-pound, M/L, No. 1 steers in selected states for the first three weeks of April. The map illustrates the typically pattern of prices across the U.S. The prices range from a high of $410.01/cwt. in Nebraska to a low of $362.66/cwt. in Mississippi, a spread of 11.5 percent from high to low. It is generally true that the highest feeder cattle prices will be in Nebraska with prices declining in all directions away from Nebraska.

Figure 1. 500 Lb. Steer Prices, M/L, No. 1, April 2025

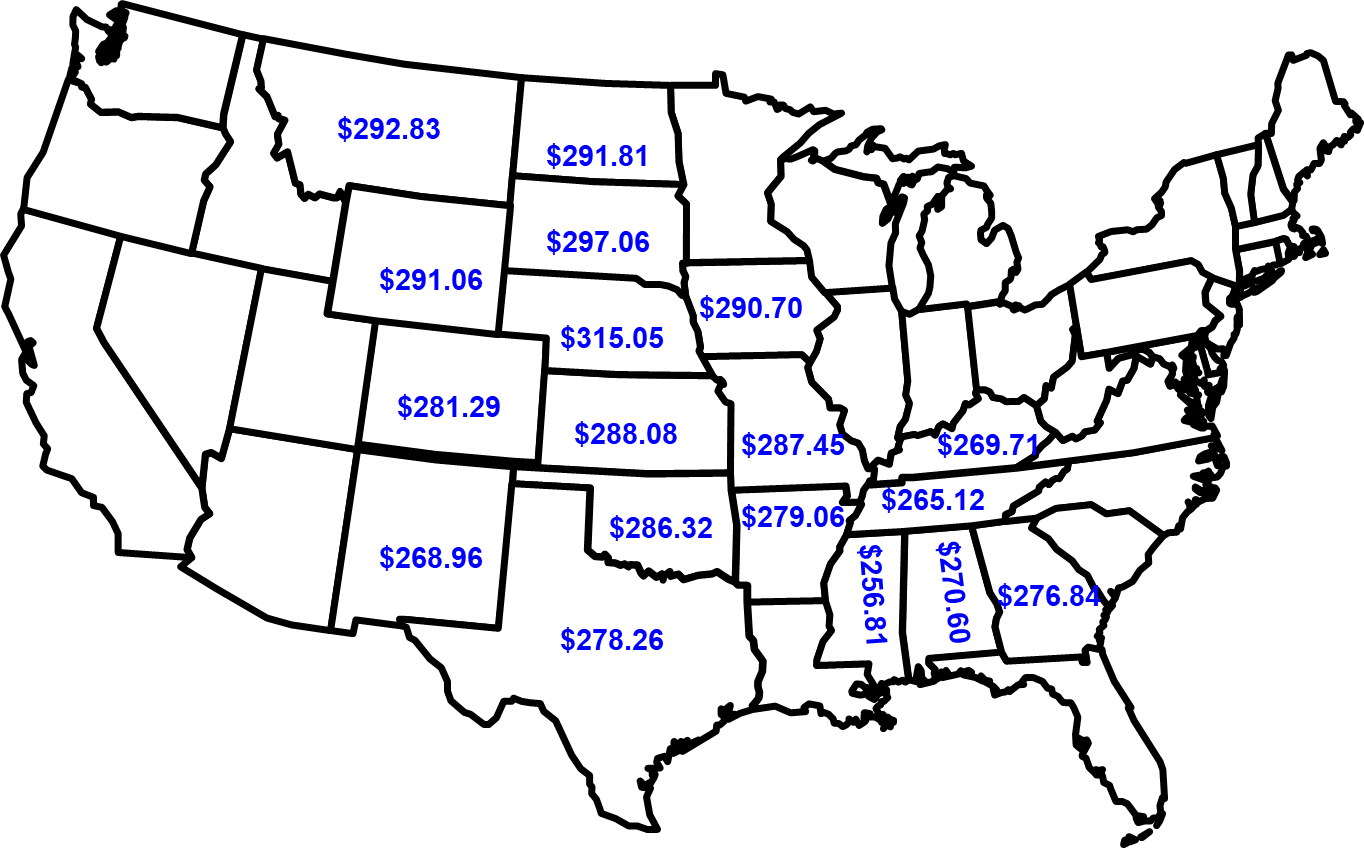

The pattern for bigger feeder cattle is similar. Figure 2 shows the average prices of 800-pound steers in April. Prices range from the Nebraska high of $315.05/cwt, to the Mississippi low of $256.81/cwt. The spread from high to low is 18.5 percent. Most of the regional price differences are explained by the transportation costs to cattle feeding areas with the discounts bigger for heavy feeder cattle, which cost more (on a per head basis) to ship.

Figure 2. 800 Lb. Steer Prices, M/L, No. 1, April 2025

Feeder cattle markets reflect the economic principle of the “law of one price”. This concept states that prices are equivalent when adjusted for differences in time, place and form. Feeder cattle prices differ according to location, weight and other factors but reflect an underlying equilibrium due to arbitrage that occurs in feeder cattle markets between cow-calf and feedlot. The stocker industry plays a critical role in this market arbitrage, providing time, place and form functions and production value for growing cattle.

Sweep Tubs vs. Bud Box

Mark Z. Johnson, Oklahoma State University Extension Beef Cattle Breeding Specialist

In a cattle working facility, the function of the crowding area, often called a “tub” is to funnel cattle into alleyway on the way to the squeeze chute or loadout. The crowding area must be designed and located so cattle can be easily moved into this area from a common sorting alley that is fed by holding pens. There are two commonly used systems that offer differing advantages which we cover this week.

Sweep Tub

The circular crowding area, with totally enclosed sides and crowding gate, is effective because the only escape route visible to the animal is through the alleyway leading to the squeeze chute or loadout. To further encourage cattle to exit crowding area, the solid crowding gate is intermittently moved toward a closed position. This effectively restricts the cattle to a successively smaller area as they move into the alleyway. A roughened concrete floor is desirable to provide an all-weather surface and for ease in cleaning. This design of cattle working facilities is to use circular crowding areas and working chutes. The circular designs take advantage of cattle’s tendency to circle and crowd toward the outside of a curved passage. The curved crowding area and working chute encourages cattle to move in a continuous flow toward the squeeze chute. Solid enclosures shield the animals’ vision from distractions outside the working area while focusing their attention on moving out of the crowding tub. When a balky animal needs to be prodded, it is only a short walk from the squeeze chute to any location along the curved working alleyway. Consequently, cattle can normally be worked in less time with a curved alleyway than with a straight one. The crowding alley also should be curved with totally enclosed sides. Cattle move more freely because they cannot view the cattlemen or squeeze chute until they approach the palpation cage or rear gate of the squeeze chute. Sloping sides in the working alleyway confine the animal’s feet and legs to a narrow path which, in turn, reduces balking. Sloping sides also reduce the capability of an animal to turn around in the crowding alley. Sloping sides are well matched to cow-calf operations because varied sizes of cattle can be worked efficiently in the same system. Recommended width for the bottom of the alleyway is 16 inches with the top at 28 inches. Emergency release panels can be constructed as movable crowding alley side panels that can be opened. An important consideration is that the cattle handler does not need to been inside the sweep tub. The handler works from the outside of the tub and alleyway while processing the cattle.

Bud Box

The same concepts regarding the alleyway leading to the squeeze chute or loadout still apply. The primary difference is the way in which cattle are coaxed into the alleyway. The Bud Box is a rectangular pen in which the alleyway leading to the chute is placed at a right angle at the point of entry. The design is simple and with proper handling techniques can be highly effective. Cattle are brought into the box and the position of the handler along the opposite side of the box stimulates cattle to move by the handler and into the alleyway. The gate that is closed behind the cattle as they moved past the alley forms the box. The Bud Box requires a basic understanding of cattle handling principles and may require additional training for inexperienced producers. The effectiveness of the design and the manner in which cattle flow into the alley is the result of the cattle handling skills and the attitude of the handler. Proper use of the box requires the cattle handler to be inside the box with the cattle.

The Bud Box contrasts the large, circular, sweep systems described above. The absence of large fabricated bends make it easier to construct. The box typically has open sides and does not require crowding gates which reduces the material cost and footprint of the facility. A typical box is 12 feet wide and 20 feet long. It is closed on one end with a gate at the other end. A Bud Box can be constructed and deconstructed from portable panels. Accordingly it offers the advantage of being tried on a temporary basis.

Summary

The decision of incorporating a Sweep Tub or Bud Box into your cattle working system should be based on considering a number of factors determining what is the best fit for your budget and type of operation. There are numerous YouTube videos available on the web showing examples of working cattle through, and the construction of, both sweep tubs and Bud Boxes.

References:

A.J. Tarpoff, et. al., Designing a Bud Box for Cattle Handling, Kansas State University Agricultural Experiment Station and Cooperative Extension Service.

Ken Apple, Raymond L. Huhnke and Sam Harp. Modern Corral Design. Oklahoma State University Cooperative Extension Service.

Brian Freking, OSU Extension area livestock specialist, covers low-stress cattle handling on SunUpTV from January 29, 2022.

The Case for Earlier Castration: Selling Steers versus Bulls

Kellie Curry Raper, OSU Extension Livestock Marketing Specialist

For cow-calf producers, your “current situation” likely includes lots of young calves running around the place with a few more expected in the near future. That also means there are additional management decisions coming your way – one of which is the castration decision. That involves a yes/no decision and – if yes - then it also involves decisions about method and timing. Today’s focus is on the yes/no decision and timing.

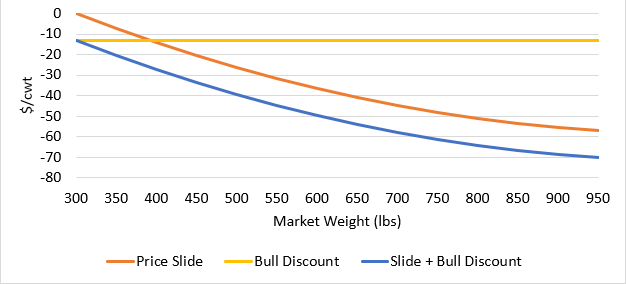

Research over time has consistently indicated price discounts for bulls sold in feeder calf markets. Oklahoma data indicates that bulls are consistently discounted relative to steers when comparing cattle of similar weight, quality, breed, and other physical and management attributes. Past OSU research has measured bull discounts in Oklahoma markets at $6/cwt to $12/cwt at different points in time. Discounts tend to increase when market price levels increase.

Preliminary research with recent Oklahoma data indicates that the bull discount per cwt is stable across weight classes at -$13.22/cwt. At first glance, that may seem counterintuitive, as we might expect the bull discount to be larger for heavier animals based on the implications of later castration on health, performance, management, and carcass quality as those animals move through the beef supply chain. And actually, it is…when you look at it on a per head basis.

The table below reflects average bull discounts per hundredweight and per head based on the latest research using our auction data. These values are relative to steers of the same weight with similar characteristics. Though the estimated discount per hundredweight does not increase by weight class, it does still result in larger per head discounts for heavier bulls. When combined with the price slide for heavier cattle, an unchanging bull discount ($/cwt) still has a proportionately larger impact on overall price per hundredweight for heavier versus lighter animals. That concept is reinforced in the table above using Oklahoma City prices for Medium/Large #1  cattle from December 2022. The bull discount as a percentage of the steer price at the corresponding weight steadily increases from 6.0% at 375 pounds to 7.9% at 875 pounds.

| Weight Class | Estimated Discount per cwt ($) | Average Discount per Head ($) | Discount Range per Head ($) |

|---|---|---|---|

| 300-399 lbs. | 13.22 | 46.27 | 39.66 - 52.75 |

| 400-499 lbs | 13.22 | 59.49 | 52.88 - 65.97 |

| 500-599 lbs | 13.22 | 72.71 | 66.10 - 79.19 |

| 600-699 lbs | 13.22 | 85.93 | 79.32 - 92.41 |

| 700-799 lbs | 13.22 | 99.15 | 92.54 - 105.63 |

| 800-899 lbs | 13.22 | 112.37 | 105.76 - 118.85 |

| 900-999 lbs | 13.22 | 125.58 | 118.98 - 132.07 |

| Pounds | Percentage |

|---|---|

| 375 lbs | 6.0% |

| 475 lbs | 6.3% |

| 575 lbs. | 6.8% |

| 675 lbs | 7.4% |

| 775 lbs | 7.2% |

| 875 lbs | 7.9% |

Figure 1. Estimated Price Slide ($/cwt) and Bull Discount, Selected Oklahoma Auctions, 2020-2022

Castrating your male calves is not free. It requires resources, including time, labor, equipment and sometimes an extra measure of patience - with the calf or with your labor resource. Also, the availability and cost of those resources varies by producer. But the market does provide incentives for including castration in your bundle of calf management practices and those incentives encourage castration at an earlier age and weight rather than when calves are older.

As Dwight Eisenhower once said, “Farming looks mighty easy when your plow is a pencil, and you’re a thousand miles from the corn field." Substitute “ranching” and “cattle chute” and I may have just guessed what you are thinking because these days my boots don’t get dirty nearly as often as yours. But the cattle market is encouraging you to consider the incentives for castration, to consider your costs for castration, and to consider adding another layer of dirt to those boots while you castrate your calves and castrate them early.