The Effects of Wind Speed and Water Pressure on Home Sprinkler Systems

Introduction

Outdoor water use can account for more than 50% of the average annual residential water use, and automated sprinkler systems make up a significant share of residential irrigation (DeOreo, Heaney and Myer, 1996). As much of half of the water used for irrigation may be wasted if it is applied in less-than-optimal conditions. One of the most common causes of sprinkler system water waste is improper (too high or too low) water pressure. Another issue that can increase water usage and decrease uniformity and efficiency is high wind speed (Tarjuelo, J. M., J. F. Ortega, J. Montero and J. A. De Juan, 2000). The combination of the two issues (improper pressure and high winds) can result in a considerable amount of water loss in the form of drift or evaporation. Monitoring the pressure of home sprinkler systems and making simple adjustments to bring it close to the recommended pressure, will help protect limited freshwater resources and effectively reduce water utility bills. It also is important to avoid irrigation during exceedingly windy conditions. The purpose of this fact sheet is to educate homeowners on the combined impact of wind speed and water pressure on sprinkler irrigation systems.

Water Pressure

The most basic objective of efficient irrigation management is to take water and apply it as uniformly as possible over a given area. Pressure has a significant impact on sprinkler flow rates, which can result in variability of the amount of water applied. In addition, improper water pressure results in pattern distortions and other irregular sprinkler operation characteristics. These irregularities cause poor irrigation application uniformity, resulting in wasted water.

In irrigation systems, the pressure is typically measured and reported in units of pounds per square inch (psi). Static pressure is the pressure of the water in the system when the system is not in operation (no water is discharged). Dynamic pressure is the water pressure when the water is moving–or the system is in operation. Pressure specifications provided for irrigation products are generally listed for dynamic pressure. Sprinkler heads operate most efficiently within a specific pressure range. In general, the standard operating pressure ranges from 15 psi to 70 psi for fixed spray heads and from 25 psi to 100 psi for residential rotors, however 30 psi is a common optimal operating pressure for fixed spray head sprinklers. The manufacturer’s specifications should be checked to ensure system pressure matches the specifications for the heads being used. A system’s pressure at the head can be obtained by using simple pressure gauges, often available where irrigation supplies are sold (Figure 1).

| Figure | Caption |

|---|---|

|

Figure 1: Example of a pressure gauge for a standard fixed spray head. (from www.slov-aqua.eu) |

High Pressure: Pressures higher than those recommended by the manufacturer can result in misting (Figure 2). The smaller droplets under high pressure are more prone to losses due to evaporation and wind drift to unintended areas before reaching the soil surface. If the pressure is excessive, pressure-regulating valves or pressure-regulating sprinkler heads can be utilized to improve the efficiency.

| Figure | Caption |

|---|---|

|

Figure 2. Example of extremely high pressure resulting in misting. (photo courtesy of Joshua Campbell, Oklahoma State University) |

Low Pressure: A steady but slow stream of water with large droplet sizes or heads that fail to pop up on a zone may be an indication of low pressure. Low pressure leads to poor water distribution causing runoff, puddling and/or dry spots. Low pressure sometimes can be caused by maintenance issues such as a broken head or leaking pipe. Also, it may be the result of poor irrigation system design, for example, too many nozzles on one zone. Depending on the cause of the problem, low pressure is generally solved by fixing the leaks, installing a booster pump to reach the required pressure or perhaps reducing the number of nozzles per zone.

Pressure Regulation

Due to sporadic pressure fluctuations in the water supply coming into many irrigation systems, pressure regulators often are installed to reduce excessive supply line pressure so it falls within the manufacturers recommended operating range, effectively reducing the misting problem. Pressure can be regulated at the individual sprinkler head, at the zone valves or at the point of connection to the mainline. Each of these are beneficial options to obtain maximum water efficiency.

Regulating pressure at the sprinkler head is done by replacing standard sprinkler heads with sprinkler heads that have built-in pressure regulation (Figure 3).

| Figure | Caption |

|---|---|

|

Figure 3. Example of a pressure-regulating sprinkler head. (photo from www.store.rainbird.com). |

Most irrigation manufacturers make pressure regulating fixed sprinkler heads, and a select few make pressure-regulating rotors. This is a relatively inexpensive way to combat high pressure on a head-by-head basis and may be ideal in a situation when there is high pressure in a zone due to only a few heads in that zone. When installing pressure-regulating irrigation heads, the bottom connection point must be used. If the side inlet is used, the pressure regulation feature will be bypassed (Figure 4). In addition, for the pressure regulation feature to work, there must be a pressure differential of 5 psi or greater. In short, this means that to regulate the operating pressure to the standard 30 psi, the dynamic pressure at the head must be greater than 35 psi.

| Figure | Caption |

|---|---|

|

Figure 4. Example of irrigation heads without and with side inlet. (photos of sprinkler heads from www.store.rainbird.com). |

Regulating pressure at the zone valve is done by choosing one of two methods that will provide zone-by-zone control. One method is to install pressure regulating valves (Figure 5) at each control zone. The second method is to install in-line pressure regulating devices (Figure 6) in each zone after the control valve. Regulating the pressure on a zone-by-zone basis might be an appropriate solution where pressure control would be needed for a zone of fixed spray heads, but not for a large zone of rotor spray heads on the same system.

| Figure | Caption |

|---|---|

| Figure 5. A control zone valve used to regulate pressure at each zone. The special solenoid attachment of the valve allows for adjustable pressure. (photo from www.arenainstalatiilor.ro). |

| Figure | Caption |

|---|---|

|

Figure 6. An in-line pressure regulator used downstream from the zone valve. (photo fromwww.preprod.senninger.com). |

Regulating pressure at the mainline connection: The pressure can also be regulated by installing a pressure reducing master valve at the point of the irrigation system’s connection to the water supply (Figure 7), which reduces pressure across the entire system. This would be a more effective and cost-efficient resolution than installing regulators on each zone or purchasing regulating sprinkler heads when the incoming water supply pressure is too high for the entire system.

| Figure | Caption |

|---|---|

|

Figure 7. A brass valve used to regulate pressure at the point of connection to the water supply. (photo from www. homedepot.com). |

Field Demonstration

A field test was conducted during the spring of 2018 at OSU’s Turfgrass Research Center to demonstrate the effects of variable water pressures and wind speeds on the performance of widely used commercial residential sprinklers. Six-inch sprinklers with 15-degree variable arc nozzles from three leading manufacturers were tested for the amount and uniformity of applied water under four operating pressures (30, 40, 60 and 80 psi) and two wind speeds (3 and 24 miles per hour (mph). The pressure was regulated by a 1-inch adjustable pressure regulator. Using a flow meter installed on the main line, the total amount of water discharged by sprinklers was recorded. The amount of water received at the ground and the application uniformity were evaluated using catch cans placed in a grid of 4 feet by 4 feet (Figure 8). Each irrigation test was conducted for 25 minutes of run time. After each test, the amount of water collected in each can was measured and used in calculation of water loss and application uniformity.

| Figure | Caption |

|---|---|

|

Figure 8. Catch cans arrangement to detect irrigation spray pattern uniformity at varying pressures and wind speeds. |

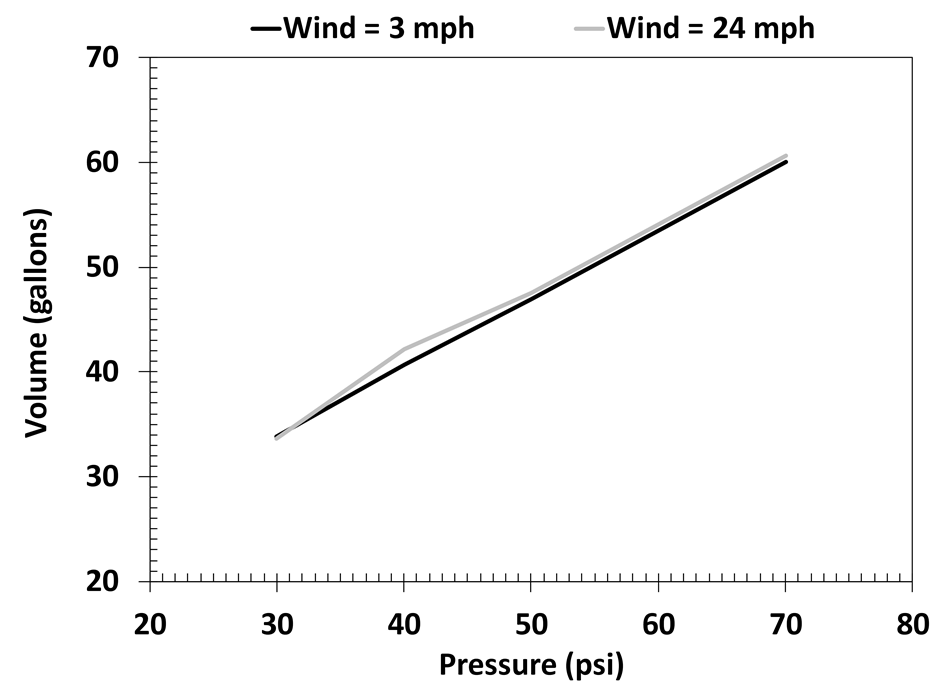

Impact of high pressure: As expected, high pressure had a direct impact on the amount of water discharged. The volume of water emitted by the sprinkler head during the same amount of time increased by 80% when the pressure increased from 30 psi to 70 psi (Figure 9). This clearly demonstrates the significant impact high pressure has on water volume discharged, which directly affects water usage and utility bills. In addition, over-irrigation resulting from higher pressure can leach nutrients from the topsoil, making them inaccessible to vegetation and increasing the risk of transporting the chemicals to downstream water bodies and polluting them.

| Figure | Caption |

|---|---|

|

Figure 9. Volume of water applied at different pressures under low- and high-wind conditions. |

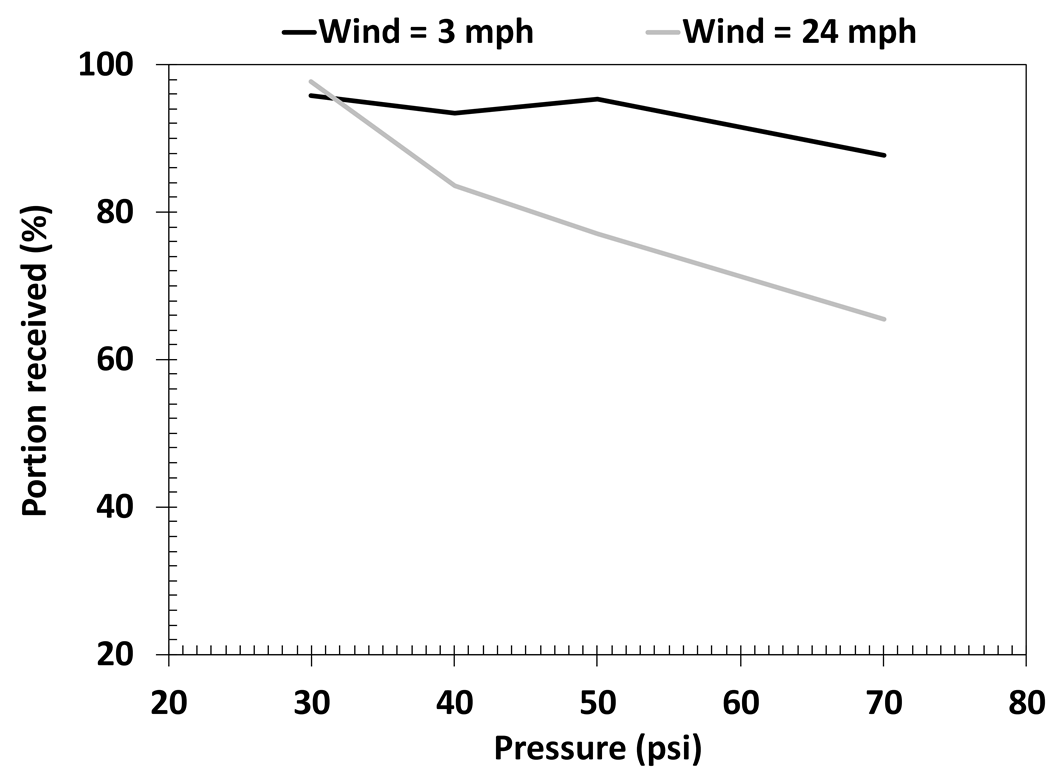

Besides the issue of using considerably more water with higher pressures, a large portion of the water discharged was not received by the intended application site as it was carried away with wind drift or evaporated before reaching the ground. In the tests conducted with windy conditions, the portion of discharged water received in the intended area dropped from 98% at 30 psi to 65% at 70 psi (Figure 10). In other words, more than one-third (35%) of the water discharged at 70 psi did not make it to the ground within the boundaries of the intended area. The impact was smaller with the low-wind conditions, with about 10% of the discharged water not making it to the ground at 70 psi.

| Figure | Caption |

|---|---|

|

Figure 10. Portion of discharged water received in the intended area at different pressures under low- and highwind conditions. |

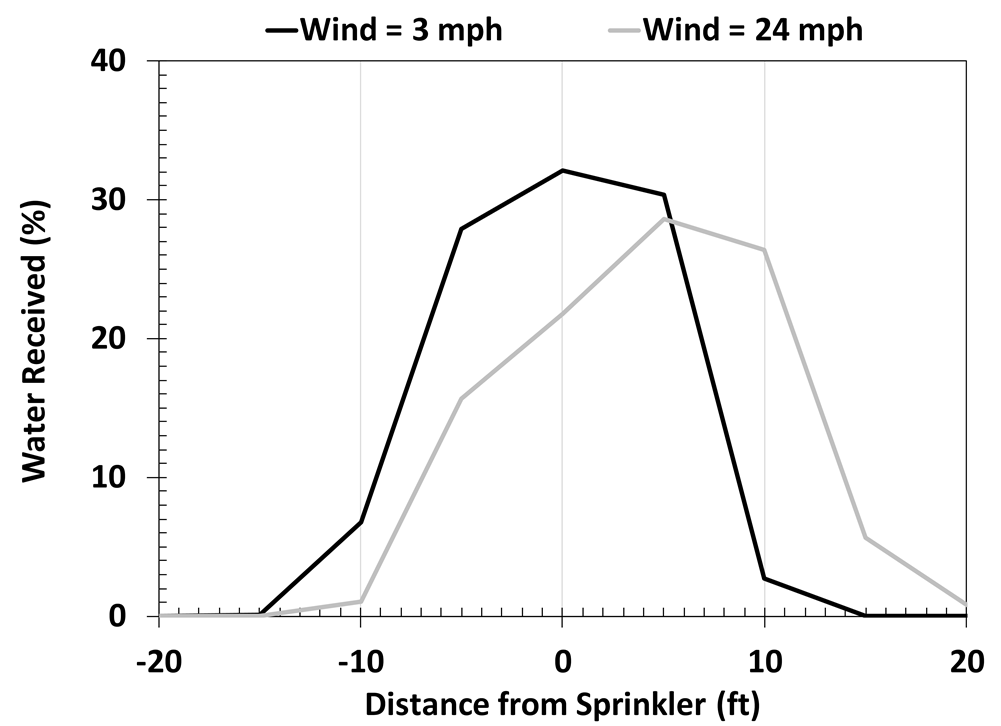

Impact of wind speed: The test was conducted under calm and windy conditions. The pattern of irrigation distribution with each condition is shown in Figure 11. The sprinkler was located at the center of the field, about 20 feet away from each side of the test area. Water distribution was uniform with calm conditions. Spray distances extended about 15 feet on either side of the sprinkler. With windy conditions, the distribution pattern was shifted by about 5 feet downwind.

Conclusion

The optimal performance of landscape irrigation systems relies heavily on their operating pressure. Pressures outside the range recommended by manufacturers can result in poor distribution and loss of water. Pressures too low can cause runoff and puddling. Pressures too high (the most common problem) can lead to over-application of irrigation water, which in turn, increases water use and utility costs. The problems of higher system pressure are exacerbated as wind speed increases, since droplets are smaller (misting) and can easily evaporate or drift under windy conditions before reaching the intended area. Owners and operators are strongly encouraged to check their system pressure and use pressure-regulating devices to correct the situation if their pressure falls outside the recommended range. Irrigating with calm conditions also should be practiced, regardless of the operating pressure. Early mornings often are an ideal time due to calmer winds. For additional information on managing pressure in the home irrigation system, please refer to the fact sheet HLA-6617, Managing Pressure in the Home Irrigation System.

References

DeBoer, D. W., Beck, D. L., & Bender, A. R. (1992). A field evaluation of low, medium, and high-pressure sprinklers. Transactions of the ASAE, 35(4), 1185-1189.

Dukes, M. D. (2006). Effect of wind speed and pressure on linear move irrigation system uniformity. Applied Engineering in Agriculture, 22(4), 541-548.

Duncan, R. R., Carrow, R. N., & Huck, M. T. (2009). Turfgrass and Landscape Irrigation Water Quality: Assessment and Management. Boca Raton: CRC Press.

Silva, L. L. (2006). The effect of spray head sprinklers with different deflector plates on irrigation uniformity, runoff and sediment yield in a Mediterranean soil. Agricultural Water Management, 85(3), 243-252.

Tarjuelo, J. M., Montero, J., Honrubia, F. T., Ortiz, J. J., & Ortega, J. F. (1999). Analysis of uniformity of sprinkle irrigation in a semi-arid area. Agricultural Water Management, 40(2-3), 315-331.

Tarjuelo, J. M., Ortega, J. F., Montero, J., & De Juan, J. A. (2000). Modelling evaporation

and drift losses in irrigation with medium size impact sprinklers under semi-arid

conditions. Agricultural Water Management, 43(3), 263-284.

Pair, C. H. (1970). Sprinkler irrigation.

William Butler DeOreo; Heaney, James Patrick; Mayer, Peter W. American Water Works Association Journal; Denver Vol. 88, Iss. 1, (Jan 1996): 79