Oklahoma Farm and Ranch Custom Rates, 2021‑2022

This Current Report summarizes data collected from Oklahoma farmers, ranchers and custom operators during the fall of 2021. Respondents were recipients of a mailing by the Oklahoma Field Office, USDA-NASS. Custom work is defined as a service or operation performed for the customer with the custom operator furnishing the farm implement, fuel, labor and other inputs directly associated with the employment. Custom operators typically do not furnish materials such as seed or fertilizer unless it is explicitly stated. With few exceptions, custom rates increased since the 2019 survey. Inflationary pressures felt in 2021 influenced the prices paid for labor, fuel, and supplies as well as machinery repair and ownership. These factors all contributed to higher rates in many situations. Approximately 675 surveys were returned with usable data.

Summary Procedure

The rates quoted herein were collected by a survey of both farmers and custom operators. A list of over 180 operations was provided from which each respondent quoted rates for only selected operations. Some respondents quoted rates for only one or two operations while others were familiar with rates for many of the machines listed. Fair rates are negotiated. Regional or state average rates may be used as a beginning point for discussion. However, differences in operations, requirements, and circumstances may impact rates.

The rates summarized on the inside pages were edited to remove those replies for which

the respondent’s interpretation of the information being requested did not match the

interpretation of other respondents.

Interpreting the Rate Tables

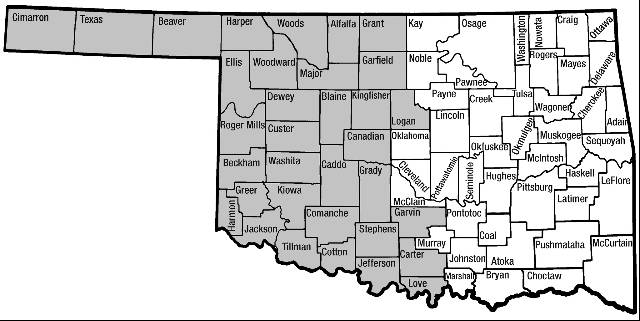

A statewide rate summary for each operation is quoted in the included table. If available, separate quotes are listed for the east and west region of the state as shown in Figure 1. The number of estimates obtained, the average rate, and the median rate are shown. The average rate for a specific operation provides an estimate of the prevailing charge with its reliability improving as the number of responses increase. Median values provide an additional measure of the central tendency of the survey response distribution. In most cases the number of observations was insufficient to allow statistical analysis. Results must be interpreted, therefore, with these limitations in mind.

Figure 1. Regions used in reporting custom rate survey results.

Figure 2 shows the distribution of survey responses for operations with at least 29 observations. For example, a distribution of 56 responses for herbicide application with a boom sprayer is one of several graphs shown. Thirteen percent reported a custom rate less than $5 per acre, 52 percent reported a custom rate between $5 and $7 per acre, 21 percent reported a custom rate between $7 and $9 per acre, 11 percent reported a custom rate between $9 and $11 per acre, and 4 percent of the respondents reported a custom rate of $11 or more per acre.

If you are interested in a rate quotation for a specific operation in an area which shows a small number of reports, consider rates for other areas of the state where the operation is more common or refer to the statewide summary. Additional adjustments for field size, terrain and soil type may be necessary.

Table. Statewide rate summary

| OPERATION | Units | Oklahoma No. | Oklahoma Avg. | Oklahoma Median | West No. | West Avg. | West Median | East No. | East Avg. | East Median |

|---|---|---|---|---|---|---|---|---|---|---|

| Discing - offset | $/acre | 12 | 10.79 | 11.5 | 10 | (D) | 11.5 | |||

| Discing - tandem | $/acre | 11 | 12.27 | 13.00 | 8 | (D) | 12.5 | |||

| Blade or wide sweeps | $/acre | 6 | 13.17 | 12.5 | 6 | 13.17 | 12.5 | |||

| Spike tooth harrow | $/acre | 5 | 7.80 | 8 | 5 | 7.80 | 8 | |||

| OPERATION | Units | Oklahoma No. | Oklahoma Avg. | Oklahoma Median | West No. | West Avg. | West Median | East No. | East Avg. | East Median |

|---|---|---|---|---|---|---|---|---|---|---|

| Applying bulk dry fertilizer | $/acre | 64 | 6.09 | 5.5 | 32 | 5.60 | 5 | 32 | 6.58 | 6.25 |

| Applying liquid fertilizer | $/acre | 20 | 5.82 | 5.9 | 16 | (D) | 5.9 | |||

| Applying liquid fertilizer, side-dress | $/acre | 8 | 7.88 | 6 | 8 | 7.88 | 6 | |||

| Applying liquid fertilizer, Lime application | $/ton | 6 | 9.92 | 9.25 | 5 | (D) | ||||

| Ground appl - herbicides with boom sprayer | $/acre | 56 | 6.48 | 6 | 35 | 5.82 | 21 | 7.58 | 8 | |

| Ground appl - herbicides, liquid broadcast or banded | $/acre | 9 | 12.04 | 6 | (D) | 13.93 | ||||

| Ground appl - herbicides, dry broadcast or banded | $/acre | 5 | 8.8 | |||||||

| Air application - herbicides | $/acre | 13 | 10.2 | 6 | 12.58 | 13.5 | 7 | 8.16 | 7 | |

| Ground appl - fungicides with boom sprayer | $/acre | 10 | 5.33 | 5.25 | 9 | (D) | 5 | |||

| Air application - fungicides | $/acre | 8 | 7.53 | 7.5 | 7 | (D) | 7.5 | |||

| Ground appl - insecticides with boom sprayer | $/acre | 6 | 5.63 | 6 | 5 | (D) | 6 | |||

| Air application - insecticides | $/acre | 8 | 6.69 | 6.88 | 6 | (D) | 6.88 | |||

| Ground application -desiccants | $/acre | 6 | 5.75 | 5 | ||||||

| Air application - desiccants | $/acre | 6 | 6 | 6 | ||||||

| Air application - growth regulators | $/acre | 6 | 6.21 | 6.5 | ||||||

| OPERATION | Units | Oklahoma No. | Oklahoma Avg. | Oklahoma Median | West No. | West Avg. | West Median | East No. | East Avg. | East Median |

|---|---|---|---|---|---|---|---|---|---|---|

| Air Seeder - conventional tillage, small grains w/o fertilizer | $/acre | 5 | 16.6 | 5 | 16.6 | |||||

| Drill small grains - conventional tillage | $/acre | 10 | 12.55 | 12.25 | 10 | 12.55 | 12.25 | |||

| Drill small grains - no-till | $/acre | 17 | (D) | 16 | 14 | (D) | 16 | |||

| OPERATION | Units | Oklahoma No. | Oklahoma Avg. | Oklahoma Median | West No. | West Avg. | West Median | East No. | East Avg. | East Median |

|---|---|---|---|---|---|---|---|---|---|---|

| Mowing hay | $/acre | 27 | 16.19 | 16 | 22 | 16.59 | 16 | 5 | 14.4 | 15 |

| Raking hay | $/acre | 27 | 4.22 | 4 | 23 | (D) | 4 | |||

| Swathing | $/acre | 116 | 16.09 | 16 | 111 | 16.11 | 16 | 5 | 15.6 | |

| Small square bales Baling a small square bale | $/bale | 20 | 2.05 | 2 | 16 | (D) | 2.05 | |||

| Cost of all haying operations (cutting to stacking sm squares) | $/bale | 10 | 2.22 | 2 | 8 | (D) | 2 | |||

| Flat rate for hauling small square bale, other trailer | $/bale | 8 | 1.05 | 1.10 | 7 | (D) | 1.10 | |||

| Large square bales Baling a large square bale, 4-foot width | $/bale | 8 | 17.58 | 18 | 5 | (D) | ||||

| Flat rate for hauling large square bale, other trailer | $/bale | 5 | 4.55 | 5 | 5 | 4.55 | 5 | |||

| Large round bales Baling a round bale, 4-foot width | $/bale | 22 | 14.67 | 15 | 9 | 15.44 | 15 | 13 | 14.13 | 15 |

| Cutting, raking, baling round bales, 4-foot width | $/bale | 166 | 22.56 | 22 | 14 | 22.71 | 23.5 | 152 | 22.54 | 22 |

| Flat rate for hauling round 4-foot width bales, other trailer | $/bale | 18 | 5.13 | 5 | 17 | (D) | 5 | |||

| Baling a round bale, 5-foot width | $/bale | 123 | 16.16 | 16 | 113 | 16.19 | 16 | 10 | 15.9 | 15.5 |

| Cutting, raking, baling round bales, 5-foot width | $/bale | 175 | 25.55 | 25 | 60 | 26.85 | 26 | 115 | 24.87 | 25 |

| Flat rate for hauling round 5-foot width bales, semi-trailer | $/bale | 7 | 4.93 | 5 | ||||||

| Flat rate for hauling round 5-foot width bales, other trailer | $/bale | 12 | 5.5 | 5 | 7 | 5.57 | 5 | 5 | 5.4 | 5 |

| OPERATION | Units | Oklahoma No. | Oklahoma Avg. | Oklahoma Median | West No. | West Avg. | West Median | East No. | East Avg. | East Median |

|---|---|---|---|---|---|---|---|---|---|---|

| Combining wheat & sm. grains (flat rate) $/acre | $/acre | 61 | 23.89 | 24 | 58 | (D) | 24 | |||

| Base rate for combining small grains | $/acre | 38 | 23.61 | 24 | 38 | 23.61 | 24 | |||

| Extra charge per bushel | $/bu. | 38 | 0.24 | 0.24 | 38 | 0.24 | 0.24 | |||

| For excess over XX bushels/acre | bu. | 38 | 21.68 | 20 | 38 | 21.68 | 20 | |||

| Flat rate for hauling small grains | $/bu. | 28 | 0.24 | 0.24 | 27 | (D) | 0.24 | |||

| Combining soybeans (flat rate) | $/acre | 9 | 27.11 | 25 | 8 | (D) | 25 | |||

| OPERATION | Units | Oklahoma No. | Oklahoma Avg. | Oklahoma Median | West No. | West Avg. | West Median | East No. | East Avg. | East Median |

|---|---|---|---|---|---|---|---|---|---|---|

| Artificial insemination, cattle | $/head | 11 | 12.09 | 10 | 7 | (D) | 12.5 | |||

| Branding cattle | $/day | 10 | 115.4 | 122 | 5 | 141 | 150 | 5 | 89.8 | |

| Branding cattle | $/head | 13 | 4.65 | 9 | (D) | 5 | ||||

| Castrating cattle | $/day | 5 | 87.8 | |||||||

| Castrating cattle | $/head | 20 | 5.28 | 5 | 9 | 3.78 | 11 | 6.5 | 6 | |

| Chute fee, cattle | $/head | 17 | 3.89 | 4 | 10 | 3.8 | 3.5 | 7 | 4.03 | 5 |

| Custom feeding - calving out cows | $/hd/day | 6 | 1.44 | 1.13 | 5 | (D) | 1 | |||

| Custom feeding - weaned calves | $/hd/day | 11 | 2.37 | 5 | 2.63 | 6 | 2.15 | 1.5 | ||

| Custom feeding - wintering pregnant beef cows | $/hd/day | 7 | 1.68 | |||||||

| Dehorning cattle | $/head | 7 | 12.64 | 10 | 7 | 12.64 | 10 | |||

| Pregnancy test cattle | $/head | 27 | 4.78 | 12 | 4.5 | 4 | 15 | 5 | 5 | |

| Processing cattle | $/day | 6 | 129.83 | 137.5 | ||||||

| Processing cattle | $/head | 14 | 14.39 | 17.25 | 7 | 14.39 | 7 | 14.39 | ||

| Spraying cattle | $/head | 5 | 2.4 | 2 | 5 | 2.4 | 2 | |||

| Worming cattle | $/head | 20 | 4.43 | 3 | 7 | 4.26 | 3 | 13 | 4.52 | 3 |

| Hauling cattle belly semi truck | $/day | 6 | 550 | 475 | ||||||

| Hauling cattle belly semi truck | $/mile | 21 | 3.92 | 4 | 13 | 4 | 4 | 8 | 3.79 | 3.9 |

| Hauling cattle trailer | $/day | 13 | 246.15 | 250 | 11 | (D) | 150 | |||

| Hauling cattle trailer | $/mile | 11 | 2.49 | 8 | (D) | 150 | ||||

| Hauling other livestock gooseneck | $/mile | 5 | 2.12 | 5 | 2.12 | |||||

| OPERATION | Units | Oklahoma No. | Oklahoma Avg. | Oklahoma Median | West No. | West Avg. | West Median | East No. | East Avg. | East Median |

|---|---|---|---|---|---|---|---|---|---|---|

| Brush hogging | $/hour | 29 | 55.24 | 60 | 7 | 62.86 | 22 | 52.82 | 55 | |

| Clearing cedar trees | $/hour | 21 | 92.24 | 85 | 17 | (D) | 85 | |||

| Dozing (D6 or smaller) | $/hour | 43 | 107.44 | 100 | 15 | 111.33 | 100 | 28 | 105.36 | 100 |

| Dozing (D7 or larger) | $/hour | 17 | 143.18 | 150 | 7 | 139.57 | 10 | 145.7 | 145 | |

| Sawing wood, chainsaw | $/hour | 10 | 31.2 | 35 | 9 | (D) | ||||

| Welding | $/hour | 28 | 54.46 | 50 | 10 | 50 | 45 | 18 | 56.94 | 50 |

| Building new fence w/materials (4-6 wire, steel posts) | $/mile | 14 | 15005 | 14816 | 7 | 16060 | 7 | 13950 | ||

| Building new fence w/o materials (4-6 wire, steel posts) |

$/hour | 16 | 26.33 | 22 | 12 | (D) | 18.5 | |||

| Building new fence w/o materials (4-6 wire, steel posts) | $/mile | 30 | 4875 | 5240 | 15 | 4757 | 15 | 4994 | ||

| Fence maintenance - inspection and minor repair | $/hour | 17 | 19.12 | 20 | 13 | (D) | 20 | |||

| Fence removal | $/mile | 8 | 47.63 | 27.5 | ||||||

(D) Regional average withheld due to disclosure.

Median values that represent an individual operation are withheld.

Reporting Regions

Area rates are summarized for the State of Oklahoma as shown in Figure 1. Regional differences are apparent in the rate table with higher rates prevailing when:

- Fields are small.

- Soils are heavy.

- Slopes are steep.

- Machines are scarce.

- Custom operators are not available.

Rates tend to be lower than expected when exchange work is common between relatives and neighbors. Under these circumstances, fixed costs of ownership such as depreciation and interest on investment (sometimes even labor) tend to be discounted when a rate is established for a particular job.

Custom Service vs. Ownership

Individual circumstances–cash flow, ownership and operating costs, labor availability, reliability and timeliness of custom operators, pride of ownership–will influence an individual’s decision on whether to buy or lease machinery and equipment or custom hire work done. A worksheet at the end of this article is designed to help evaluate the cost of machinery ownership and operation

Possible Advantages of Using Custom Operations

• Ownership costs are avoided.

• Capital and labor can be channeled to other uses.

• Machine use can be readily adjusted to changes in crop mix and market conditions.

• Specialized operations may benefit from experience and skilled operator.

• Jobs may be completed faster using several machines.

Possible Disadvantages of Using Custom Operations

• Service may not be available at the ideal time.

• Reliability of the custom operator may not be known.

• Rates may be excessive during the optimal time.

Each manager must choose the best combination of owned and hired machines. The quotations here will be helpful in estimating custom costs and to provide a base figure for agreement on a rate when well established local rates are not available. If you have questions, ask your Extension Educator- Agriculture or Area Agricultural Economics Specialist for additional information.

Considerations to Keep in Mind

Be aware that there is a wide variation in rates charged for most jobs, even within the same geographic area, partly because some custom work is done for friends, relatives, and neighbors at reduced rates, partly because some custom work is done late by farmers who do their own work first and therefore do not attempt to include the full cost of machine ownership in their rates, and partly because it is easy to under estimate the full cost of ownership and operation of machinery.

A small number of reports for a given custom rate in a particular area may not be representative. In this case, it is particularly important to check rates in other areas or statewide where a larger number of reports are found.

Costs of Ownership and Operation

The management decision to own a machine, to custom hire operations performed, or to custom perform operations is partially determined by cost, which is heavily influenced by the amount of use realized over the period of machine ownership. Estimates of fixed and variable costs per hour can be approximated using the following steps. Unless accurate records are used to estimate costs, variability in machine and operator efficiencies can cause actual results to be significantly different from estimated results.

| Steps | Estimate for | Formula | worksheet | Estimated amount |

|---|---|---|---|---|

| A | Acres per hour | Acres covered in normal day ÷ hours in normal day = | acres ÷ hours = | = |

| B | Average investment | (Original cost + Trade-in value) ÷ 2 = | ($ + $) ÷ 2 = | = $ |

| C | Annual Depreciation | (Original cost – Trade-in value) ÷ (Number of years owned) = | ($ – $) ÷ years = | = $ |

| D | Annual Interest | Average Investment x Interest rate = | $ x % = | = $ |

| E | Annual Taxes | Average Investment x Personal Tax rate (1) | $ x % = | = $ |

| F | Annual Insurance | Average Investment x Insurance rate(2) = | $ x % = | = $ |

| G | Total Annual Ownership Costs (Sum of C through F) | = $ | ||

| H | Ownership Costs per acre | Ownership Costs ÷ Acres Per Year = | $ ÷ acres/year = | = $ |

| I | Repairs Per Acre | Repairs (3) ÷ Acres Per Year | $ ÷ acres/year = | = $ |

| J | Fuel Cost Per acre | Fuel Price x Gallons Per Hour ÷ Acres Per Hour = | ($ / gal x gal / hour) ÷ acres/hour = | = $ |

| K | Labor Cost Per acre | Daily Wages ÷ Acres Per day = | $ /day ÷ acres/day = | = $ |

| L | Total Cost Per Acre = Sum of items H through K above | = $ | ||

- (1) Use local tax rate if known. One to two percent is a reasonable “guesstimate”.

- (2) Use own insurance rate if known. One-half to one percent is a reasonable “guesstimate”.

- (3) Use your repair expense data, if available. One percent of original price for each year machine is kept is a rough estimate; e.g., 10% per year if machine is to be used for 10 years.

Roger Sahs

Extension Assistant Specialist