Fire Effects: Fencing

- Jump To:

- Barbed Wire

- Wood Posts

- Steel Posts

- References

The effects of fire on livestock fencing is a concern following wildfires, as well as before applying prescribed fire. There are many opinions and beliefs about what fire does to fencing materials. This fact sheet will present findings from several studies that investigated the impacts of fire on fencing materials in grasslands.

Barbed Wire

All zinc coated 12 1⁄2 gauge two or four-point barbed wire in the U.S. is manufactured to quality standards set by the American Society for Testing and Materials (ASTM). These standards are: size 12 1⁄2 gauge, nominal diameter of zinc coated wire 0.099 inch (2.51 mm), minimum weight of zinc coating 0.28 oz per square foot (85 grams per square meter), and breaking strength 950 pound force (4,230 Newtons) of both wires together. In the manufacturing process, barbed wire goes through a couple of temperature extremes. First, it is immersed in a 2,500 F (1,371 C) lead bath. This hardens the wire, creating tensile strength and keeps it from stretching during the fence-building process. Secondly, the zinc or galvanized coating is applied at 840 F (200 C). While many grassland fires can reach these temperatures or even higher, the duration of heat is not long enough to melt the coating or impact the tensile strength of the base wire as a study proves.

The effects of fire on livestock fencing is a concern following wildfires, as well as before applying prescribed fire. There are many opinions and beliefs about what fire does to fencing materials.

A study was conducted west of Stillwater in tallgrass prairie that compared known-age barbed wire from different heights above ground level, that were either unburned, burned through one, two and six times, or unused wire from the same lot. The results showed no differences in breaking or tensile strength at any strand height or fire treatment (Table 1). This study indicates that even repeated fires in tallgrass prairie fuels do not impact the strength of barbed wire. You might have seen barbed wire sag from the heat when a fire passes through it. However, as it cools it tightens back up to its original tension. This sagging and retightening has no effect on wire tensile strength.

Table 1. Breaking strength of double-strand, 2-point barbed wire. ASTM minimum standard for breaking strength of new 12 1⁄2 gauge barbed wire is 4,230 Newtons (N). (From Engle et al. 1998).

| Number of Fires | Breaking Strength (N) | |

|---|---|---|

| Unused wire | 5,160 | |

| 1 | 5,030 | |

| 2 | 4,980 | |

| 6 | 5,160 |

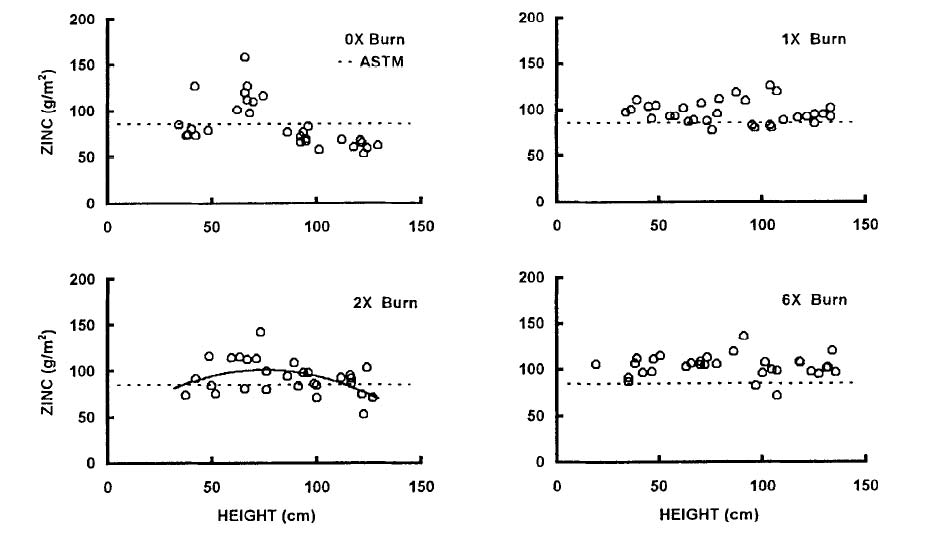

Barbed wire is coated in zinc to prevent corrosion and the study found that repeated fires had no impact on the zinc coating of the wires at any height. It showed that more than half of the 32 samples of unburned wire measured below the ASTM standard of 0.28 ounces per square foot (85 grams per square meter), while only three of the 32 samples burned through six times were below the ASTM standard (Figure 1). Often after a fire, what appears to be rust may be observed on galvanized barbed wire. This “rust” is actually a latent stain caused by the iron impurities found in the zinc coating. This stain can be easily removed, with no signs of pitting or damage to the zinc coating or underlying steel wire.

Figure 1. Zinc coating remaining on barbed wire at various heights above ground level and fire treatments. The dashed line is the ASTM minimum standard for zinc coating on 12½ gauge barbed wire. (From Engle et al. 1998).

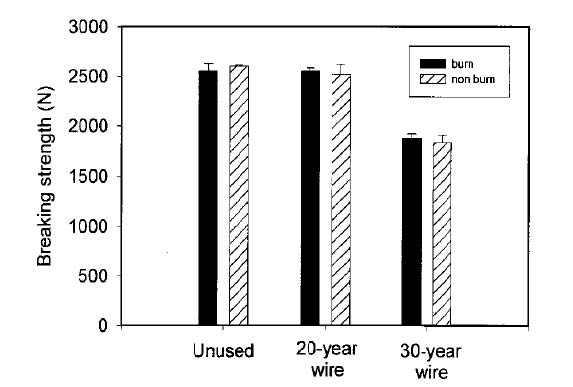

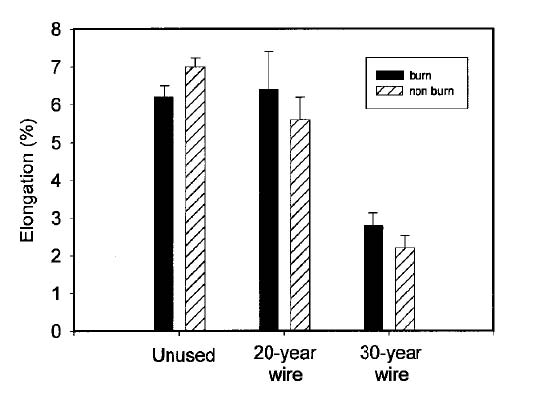

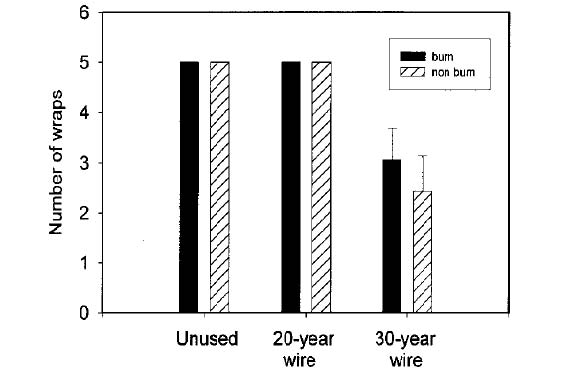

Another common belief is that fire causes older, corroded barbed wire to become brittle and easier to break. A study was conducted to examine fire impacts on older corroded barbed wire that had already lost its zinc coating. This study compared the effects of one fire versus no-fire on two different aged classes of corroded barbed wire (20 and 30 years old) against an unused/unstretched sample. The study found that fire had no impact on the breaking strength, percent elongation (how much stretch the wire had) and wrap test (ductility) (Figure 2). Age, regardless of fire treatment, had the most significant impact on barbed wire strength and ductility. Following a fire, broken wires are often observed in older fence lines. This is could be due to the grass, brush and trees being removed by the fire, exposing wires that had been broken years before, but never noticed.

Figure 2. Breaking strength (N=Newtons), permanent elongation, and number of wraps before single strand failure of older corroded barbed wire after one fire. (From Engle and Weir 2000).

Wood Posts

There has been no specific study looking at the impacts of fire on traditional wood line or corner posts. Two studies did investigate the use of fire retardant preservatives on wood posts. Ignition of wood posts during a wildfire or prescribed fire will vary with post age; size; state of decay and presence of large cracks to allow embers to settle in; and wood type, along with soil and post moisture content. Wooden post moisture content is probably the most significant factor that determines ignition. Typically, if adequate soil moisture is present, the post will absorb this and have a higher fuel moisture content, making it more difficult to ignite. Reduced moisture content is the reason most wooden posts are burned during major wildfire events. Massive wildfires mainly occur during drought conditions, when soil and fuel moisture is very low, allowing for higher combustion of larger-sized wood fuels like corner posts.

Ignition of wood posts during a wildfire or prescribed fire will vary with post age; size; state of decay and presence of large cracks to allow embers to settle in; and wood type, along with soil and post moisture content. Wooden post moisture content is probably the most significant factor that determines ignition. Typically, if adequate soil moisture is present, the post will absorb this and have a higher fuel moisture content, making it more difficult to ignite.

Steel Posts

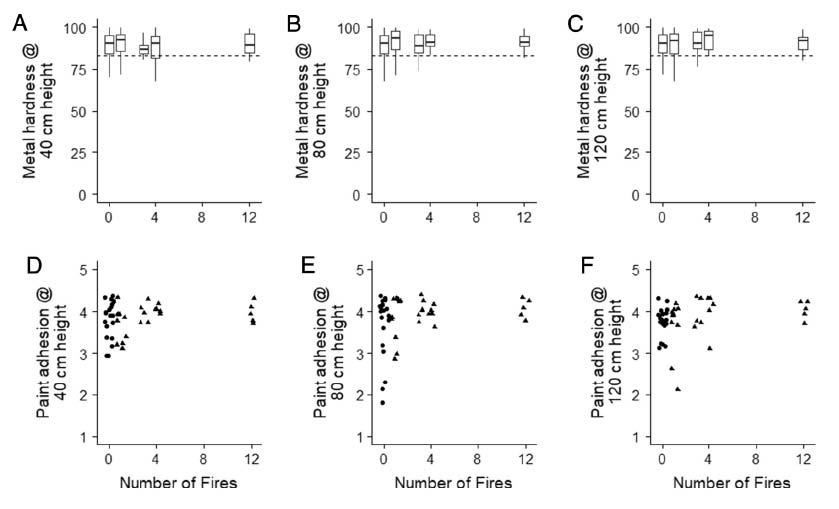

ASTM also has quality measurements for steel T-posts and the finish applied to them. The standards include: dimensions, nominal weight per foot and steel hardness. The finish must be of one or more coats of weather-resistant enamel paint. A study at OSU looked at the impacts of fire type (prescribed and wildfire) and age since construction of the T-posts (four to 35 years). Additionally, the study compared post hardness and paint adhesion at 16 inches (40 centimeters), 32 inches (80 centimeters) and 48 inches (120 centimeters) above ground level on posts that had no fire, one, three or 12 prescribed fires and one or two wildfires (Table 2). Similar to the study on barbed wire, the study found no differences in post hardness related to the number of fires, fire type or the age of construction, with all posts testing above the ASTM minimum standard of 83 Rockwell B Hardness (Figure 3). Paint adhesion between burned and unburned T-posts was not different, but construction age was found to significantly impact paint adhesion properties. Results from the adhesion tests showed T- posts, unburned or burned, either scored 3A-Jagged removal of paint along incisions up to 0.06 inch (1.6 millimeters) or 4A-Trace peeling or removal of paint along incisions (Figure 3).

In summary, there is no evidence that barbed wire or steel fence posts are negatively affected by prescribed fire or wildfire in grasslands. It should be noted that all of these studies were conducted in tallgrass prairie with high fuel loads. Fires in tallgrass prairie release a tremendous amount of heat and energy, but these fires are wind-driven and move quickly, not allowing temperatures to stay high for very long. These studies did not look at fences that are not managed and overgrown with cedars and other trees. Many times, when these unmanaged fences burn, they expose damages caused by neglect before the fire. Broken wires or wires that appear stretched, are not due to fire, but trees growing through them.

There is no evidence that barbed wire or steel fence posts are negatively affected by prescribed re or wild re in grasslands.The main reason is these grassland res are wind-driven and move quickly, not allowing temperatures to stay high for very long.

Table 2. Location, date of fence installation, type and number of fires, and date of fire occurrence for all T posts sampled from the OSU Research Range. (From Weir and Starns 2019)

| Site | T Posts Installed (year) |

Fire Treatment (no. of times) |

Fire Occurrence (year) |

|---|---|---|---|

| HQ P4 | 2013 | Prescribed fire (1) No fire |

2017 |

| Section 4 | 1982 | Prescribed fire (1) Wildfire (2) No fire |

2010 1991, 2009 |

| CTER P 19 East | 1983 | Prescribed fire (3) | 2000, 2015, 2017 |

| CTER P 19 North | 1983 | Wildfire (1) No Fire |

1996 |

| CTER P1 | 1982 | Prescribed fire (12) No Fire |

1986, 1987, 1988, 1990, 1993, 1996, 1999, 2002, 2005 2013, 2015 |

Figure 3. Upper graphs: Rockwell B Hardness of T-posts at heights of 16 inches (40 centimeters), 32 inches (80 centimeters) and 48 inches (120 centimeters) above ground level for unburned and burned posts. Dashed line is minimum ASTM requirement for T-post hardness. Lower graphs: Paint adhesion scores from testing at same heights for unburned (circles) and burned posts (triangles). (From Weir and Starns 2019)

References

Engle, DM, JR Weir, DL Gay, BP Dugan. 1998. Grassland re effects on barbed wire. Journal of Range Management 51:621-624.

Engle, DM, JR Weir. 2000. Grassland re effects on corroded barbed wire. Journal of Range Management 53:611-613

Weir, JR, HD Starns.2019.Grassland re effects on steel fence posts. Rangeland Ecology

and Management 72:411-413

ASTM 1995. Annual book of ASTM standards. Section 1. Iron and steel products. Volume 01.06. Coated steel products.

ASTM1995.AnnualbookofASTMstandards.Section3.Metals test methods and analytical procedures. Volume 03.01. Metals-Mechanical testing: elevated and low-temperature tests: metallography.

ASTM 2009. ASTM D3359-09. Standard test methods for measuring adhesion by tape test. ASTM International. West Conshohocken, PA, USA.

ASTM 2013. ASTM A702-13. Standard speci cation for steel fence posts, hot wrought. ASTM International. West Conshohocken, PA, USA.

Evans, PD, P Beutel, RB Cunningham, CF Donnelly. 1994. Fire resistance of preservative-treated

slash pine fence posts. Forest Products Journal 44:37-39.

McCarthy, DF, LD Bezemer, WG Seaman, EWB Dacosta. 1972. Development and evaluation

of a leach resistant re retardant preservative for pine fence posts. Institute of

Wood Science Journal 6:24-31.