2019 Oklahoma Cotton Harvest Aid Guide

Harvest aids in cotton are utilized to remove foliage, inhibit regrowth and open bolls to allow for timely harvest operations so yield and quality losses due to weathering can be minimized. Defoliation and boll opening are natural processes governed by plant hormones. Harvest aids are used to speed up these naturally occurring processes. The timing of harvest aid applications is primarily governed by crop maturity, but environmental conditions, the products used and rates applied also play a role.

The timing of harvest-aid applications should be made on a field-by-field basis, as no two fields experience identical growing conditions season-long. Harvest aids can hasten the natural process of defoliation and boll opening, but they do not influence boll (or fiber) maturity. Boll maturity can be determined by slicing the boll horizontally to expose the developing lint and seeds. A mature boll should be firm and difficult to slice, with mature seeds (fully developed cotyledons with little liquid or “jelly” in the seeds) with a dark seed coat and the lint stringing-out when the two halves are separated. Occasionally, there can be a “fruiting gap” due to environmental or insect stress, which results in several consecutive nodes of aborted fruit. This can occur on bottom, middle or upper nodes of the plant, depending on the timing of the stress. When this occurs, it can give a skewed representation of the maturity of the field.

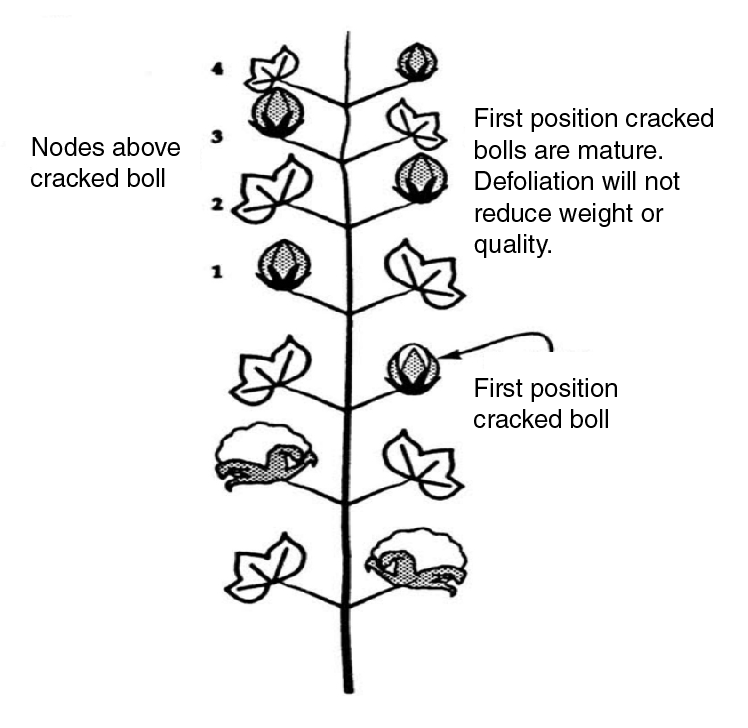

Recommendations regarding the timing of applications are based on crop maturity status and there are various methods used to determine this status. The most common recommendations are to time applications when: 1. the uppermost first position harvestable boll is four mainstem nodes above the uppermost first position cracked boll (4 NACB; Figure 1) or; 2. 60 to 70 percent of the harvestable bolls on the plant are open (60 to 70 percent open bolls). However, because 4 NACB doesn’t necessarily equate to 60 to 70 percent open bolls, a combination of the two methods may be used. Boll distribution, environmental conditions, variety maturity class and management practices can impact both of these measurements and in-field variability between NACB and percent open bolls can be high, so taking into account the status of the majority of the plants in the field is recommended. Both of these measurements should be based only on the harvestable bolls on the plants, so only mature bolls should be taken into account. Harvestable bolls consist of bolls that are currently open, mature but not yet open or far enough along in the maturating process they are expected to open by harvest assuming favorable conditions and timely application of harvest aids.

A wide array of harvest aid products are available for use in cotton. These products typically fall into one of four general categories; boll openers, defoliants, regrowth inhibitors and desiccants, although some products may serve multiple purposes. For example, boll openers (active ingredient is ethephon) speed up the natural process of boll opening and will also provide some defoliation especially in warm, sunny conditions. Defoliants assist in removing leaves from the plant and desiccants hasten leaf dry-down but typically result in leaves staying attached to the plant, otherwise known as leaf stick. The selection of products should be based on what is needed to prepare the crop for harvest, the environmental conditions at application and in the short-term (three to five days) following application and the yield potential, which should influence the amount of financial investment that is justifiable.

Regardless of product selection or crop condition, there are a few key considerations that need to be kept in mind regarding harvest aid performance and crop response.

Figure 1. Determining nodes above cracked boll (NACB). Source: Guthrie, D., Cothren, T., and Snipes, C. 1993. The art and science of defoliation. Cotton Physiology Today Volume 4, No. 7, National Cotton Council, Cordova, TN.

Harvest aid applications

- Spray coverage is key with carrier volume being critically important. Recent work from across the Cotton Belt has determined that increased carrier volume (10 to 15 gallons per acre) results in greater coverage and more rapid and effective defoliation and regrowth inhibition.

- Coarse of smaller droplet sizes are recommended for optimum coverage.

- Ground speed – slower typically allows for better coverage, particularly to penetrate the crop canopy. Take ground speed adjustments into consideration when calibrating.

Crop Condition

- Terminal regrowth – typically caused by excess moisture and/or excess nitrogen in

conjunction with temperatures that favor growth.

- Can be significant if conditions are favorable for vegetative growth and can lead to high module moisture and lint staining.

- Typically controlled by tribufos or protoporphyrinogen oxidase (PPO) inhibitors products, but leaf removal will be key. Stuck leaves on the top of the plant can result from use of a desiccant which is undesirable, particularly if a picker is being used for harvest.

- Plant growth regulators (PGRs) won’t affect or inhibit regrowth – internodes on regrowth are very compact and leaf area is only reduced 5 to 10 percent while leaf thickness is increased. Once regrowth is observed, PGRs won’t have an impact on internode length.

- Basal (juvenile) regrowth – can occur after plant has been defoliated if conditions

that favor growth are present. Sunlight is able to penetrate canopy and initiate growth

on the lower axillary nodes of plants.

- This can also occur in fields where verticillium wilt has resulted in premature defoliation. If verticillium wilt is present and caused significant defoliation, watch for the initiation of regrowth at the bottom of the plant.

- Tribufos, PPO defoliant or thidiazuron + diuron products are typically effective in removing juvenile regrowth.

Timeline for Harvest-Aid Effect

Minimal time typically needed for full effect from applied product. This can increase with adverse conditions (cool weather, drought toughened plants, etc.).

- Defoliants – (tribufos or PPOs) seven days

- Defoliants/regrowth control – (thidiazuron or thidiazuron + diuron) 14 days

- Boll openers – (ethephon) seven to 14 days.

- Desiccants – (paraquat) five to seven days.

Harvest Method

- Emphasis for picker-harvested cotton is on maximal leaf drop to avoid plant material being collected with harvested lint. Although pickers will not remove small immature bolls on the plant, boll opening is key as the lint should be accessible to the spindles to be effectively removed from bolls. Desiccants are occasionally used as a followup after defoliants, but high rates should be avoided so plants are still able to bend as they move through row units.

- Emphasis for stripper-harvested cotton is on desiccation. On-board field cleaners will aid in removing some plant material and burrs collected at harvest, but plant material needs to be dry to avoid wet material clogging field cleaner saws. Small unopened bolls that were desiccated will be removed by field cleaner.

The following tables provide harvest aid recommendations and general information on the function of the different active ingredients, use rates and some common names of products. As always, follow the label regarding use rates and adjuvants/surfactants. Many product labels will also include information on rates based on environmental conditions (mainly temperature and humidity).

Table 1. Active ingredients, common trade names, and application considerations.

| Trade Names (Manufacturer) |

Active Ingredients | Considerations |

|---|---|---|

| Defoliants | ||

| Organophosphate | ||

| Folex 6 EC (Amvac) | Tribufos | Reduced activity under low temps, low humidity, or stressed plants. Use higher rates under these conditions. |

| PPO Inhibitor | ||

| ETX (Nichino) | Pyraflufen-ethyl | Addition of COC recommended. |

| Aim EC (FMC) | Carfentrazone-ethyl | NIS required at higher temps, COC required at lower temps. 7-day PHI. |

| Display (FMC) | Carfentrazone-ethyl + Fluthiacet-methyl | |

| Resource (Valent) | Flumiclorac pentyl ester | Addition of COC or MSO; NIS if warm, sunny conditions. |

| Sharpen (BASF) | Saflufenacil | Addition of MSO + AMS or UAN required. |

| Defoliants/Regrowth Inhibitor | ||

| Freefall (Nufarm) Daze (Winfield) Klean-Pik (Mana) Take Down (Loveland) Thidiazuron (Arysta) |

Thidiazuron | Higher use rates and addition of COC with temps < 65 F, or in drought conditions. Thidiazuron alone not typically recommended due to low overnight temps in the High Plains. |

| Ginstar EC (Bayer) Cutout (Nufarm) Adios (Arysta) Redi-Pik (Mana) |

Thidiazuron + diuron | Minimum 12 hours rain-free after application for optimal performance. Higher rates required if low humidity is present. |

| Boll Opening | ||

| Super Boll (Nufarm) Boll’d (Winfield) Boll Buster (Loveland) Ethephon 6 (Arysta) Several other trade names |

Ethephon (6 lbs. ethephon/gal) | 7-day PHI. Minimum 6-hour rain-free period for optimal performance. Higher rates under cool and/or dry conditions, or on toughened/drought stressed foliage. |

| Flash (Helena) | Ethephon (3 pounds) | |

| Finish 6 Pro (Bayer) | Ethephon (6 pounds) + cyclanilide | |

| First Pick (Nufarm) | Ethephon (2.28 pounds) + urea sulfate | |

| Desiccants | ||

| Gramoxone Inteon (Syngenta) Gramoxone SL 2.0 (Syngenta) |

Paraquat (2 pounds paraquat/gal) | Addition of NIS recommended. |

| Firestorm (Chemtura) | Paraquat (3 pounds) | |

| Parazone 3 SL (Amvac) Several other trade names |

COC - crop oil concentrate; NIS Ð nonionic surfactant; MSO Ð methylated seed oil; AMS Ð ammonium sulfate; UAN Ð urea ammonium nitrate; PHI Ð pre-harvest interval.

Table 2. Harvest aid decision table (all units in per acre basis). This lists several available

options but is not mean to be exclusive.

| Crop Condition | Harvest Aid Options1 |

|---|---|

| Short stature (12 to 14 inches); low/limited yield potential (less than 500 pounds per acre). Specific tank mix selection should be based on crop requirements for harvest preparation (boll opening, leave removal, regrowth inhibition and/or desiccation). | PPO inhibitor defoliant (rates vary) with or without the addition of a boll opener. |

| PPO inhibitor defoliant (rates vary) FB2 PPO inhibitor defoliant (rates vary).3 | |

| Paraquat formulation at 8 to 16 ounces (2 pounds) or Paraquat at 5.3 to 10.7 ounces (3 pounds). | |

| Paraquat at 4 to 12 ounces (2 pounds) FB paraquat up to 32 ounces (2 pounds) or paraquat at 2.6 to 5.3 ounces (3 pounds) FB paraquat up to 21 ounces (3 pounds).4 | |

| Paraquat at 6 to 24 ounces (2 pounds) or Paraquat at 4 to 6.7 ounces (3 pounds) + tribufos at 8 to 16 ounces or PPO inhibitor defoliant (rates vary).5 | |

| Medium stature (15 to 24 inches); 500+ pounds per acre yield potential. Specific tank mix selection should be based on crop requirements for harvest preparation (boll opening, leave removal, regrowth inhibition and/or desiccation). | Ethephon (6 lb.) at 16 to 42 ounces or (ethephon + cyclanilide) at 16 to 42 ounces tribufos at 8 to 16 ounces. |

| Ethephon (6 pounds) at 16 to 42 ounces or (ethephon + cyclanilide) at 16 to 42 ounces + (thidiazuron + diuron) at 3 to 8 ounces. | |

| Ethephon (6 pounds) at 16 to 42 ounces or (ethephon + cyclanilide) at 16 to 42 ounces + PPO inhibitor defoliant (rates vary).3 | |

| PPO inhibitor defoliant (rates vary)3 + tribufos at 8 to 16 ounces or PPO inhibitor defoliant at 0.6 to 8 ounces3 + (thidiazuron + diuron) at 3 to 8 ounces. | |

| PPO inhibitor defoliant (rates vary)3 FB2 PPO inhibitor defoliant (rates vary).3 | |

| Paraquat at 6 -24 ounces (2 pounds) or paraquat at 4 to 16 ounces (3 pounds) + tribufos at 8 to 16 ounces. Stripper-harvested only. | |

| Paraquat at 6 to 24 ounces (2 pounds) or paraquat at 4 to 16 ounces (3 pounds) + PPO inhibitor defoliant (rates vary).3Stripper-harvested only. | |

| Paraquat at 4 to 8 (2 pounds) ounces FB paraquat up to 32 ounces total (2 pounds)3 orparaquat at 2.6 to 5.3 ounces (3 pounds) FB Paraquat up to 21 ounces total (3 pounds)4 Stripper-harvested only. | |

| (Ethephon + urea sulfate) at 48 to 64 ounces + (thidiazuron + diuron) at 3 to 8 oz. | |

| Tall stature (> 24 inches); 1,000+ pounds per acre yield potential. Specific tank mix selection should be based on crop requirements for harvest preparation (boll opening, leave removal, regrowth inhibition and/or desiccation). | Ethephon (6 pounds) at 21 to 42 ounces or (ethephon + cyclanilide) at 21 to 42 + tribufos at 8 to 16 ounces. |

| Ethephon (6 pounds) at 21 to 42 ounces or (ethephon + cyclanilide) at 21 to 42 ounces + (thidiazuron + diuron) 3 to 8 ounces. | |

| (Ethephon + urea sulfate) at 48 to 112 ounces + (thidiazuron + diuron) at 3 to 8 ounces. | |

| Ethephon (6 pounds) at 21 to 42 ounces or (ethephon + cyclanilide) at 21 to 42 ounces + PPO inhibitor defoliant (rates vary).3 | |

| (Ethephon + urea sulfate) at 48 to 112 ounces + PPO inhibitor defoliant (rates vary).3 | |

| Other Conditions. Desiccating application for stripper harvest preparation (not to be used for picker-harvested cotton). Conditioning treatment for late-maturing cotton. Apply after daily heat units drop below 5, target seven days before first killing freeze date. | Paraquat at 16 to 32 ounces (2 pounds) or paraquat at 11 to 21 ounces (3 pounds). |

| Paraquat at 4 to 16 ounces (2 pounds) or paraquat at 2.6 to 10.7 ounces (3 pounds). | |

| Ethephon (6 pounds) at 21 to 42 ounces. |

1 Actual rates needed will depend on weather conditions (high and low temperatures,

humidity). Higher label rates are typically recommended under cooler and dryer conditions.

Check the label for specific details on rates.

2 FB = followed by.

3 Rates will depend on product selected; check the label for appropriate rates for

the selected product. No more than: 3.2 ounces per acre total of Aim EC, 2.0 ounces

per acre total of Display, 2.0 ounces per acre total of Sharpen, 3.4 ounces per acre

total (no more than two applications) of ETX, and 14 ounces per acre (no more than

two applications, max of 8 ounces per single application) of Resource may be applied

during the growing season.

4 No more than 32 ounces per acre of 2 pounds paraquat active ingredient or 21 ounces

per acre of 3 pounds paraquat active ingredient may be applied as a harvest aid in

up to four applications. Subsequent applications should depend on the green leaves

remaining and the rate applied in the first application; use higher rates if excessive

regrowth is present.

5 Labeled tank mix partners for paraquat include Folex, ETX and Sharpen.

Seth Byrd

Assistant Professor, Extension Cotton Specialist