Basics of Pressure Treatment of Wood

Wood is an excellent renewable building material. However, when a wood product is used in contact with the ground or exposed to high moisture conditions it may be subjected to biological and insecticidal deterioration. As a result of termite or fungi attack, wood from most species can be destroyed within five to eight years. To extend the service life of wood to 20-25 years in moist environmental conditions, it is important to use pressure treatment methods. The objective of this fact sheet is to summarize the most commonly used pressure treatment methods, the basic principles, and some of the chemicals used for such processes.

Preparing Wood for Pressure Treatment

The purpose of wood pressure treatment is to force preservative chemicals deep into the cellular structure of the wood. The chemical acts as a barrier between the wood and biological deterioration agents, so that the service life of the wood can be substantially increased. For most pressure treatment processes, moisture in wood is reduced before the application of the chemical. In the case of roundwood treatment, logs should be debarked using various equipment, such as rosserhead or ring debarkers. Incising is another process to prepare wood for treatment. Sharp steel teeth are pressed into the sides of timber or poles to increase the penetration of the chemical into the wood during the incising process as shown in Figures 1 and 2. Table 1 also shows the effect of incising on the retention level of eastern spruce.

Figure 1. Incising process.

Figure 2. Incised lumber to improve the penetration of the treatment chemical.

Treatment Processes

In a typical pressure treatment process, wood is placed in a horizontal cylinder up to 150 ft. long and 7 ft. in diameter as shown in Figure 3. The cylinder is flooded with the chemical followed by a cycle of pressure and vacuum. Pressure treatment methods are classified into two basics groups: full-cell and empty-cell processes. In the full-cell method, both cell wall and lumen are filled with the chemical, while the objective of empty-cell process is to retain preservative in only the cell wall. The full-cell method is the oldest treatment process and was invented in 1838 by John Bethell. This method is generally used where a large amount of preservative is needed for certain applications such as treatment of utility poles, farm fence, bridge timbers, and pier timbers. This process results in high retention, but not necessarily deeper penetration than that of other processes.

Figure 3. Pressure treatment tank (Courtesy of Julian Lumber Treatment Company)

In a typical full-cell treatment, the process begins with an initial vacuum to evacuate

air from the cylinder. Later, the tank is filled with the preservative chemical and

the pressure is increased to 140-150 psi for several hours. Once the pressure time

is completed, the preservative is drained from the tank, and then a vacuum is applied

to clean the excessive chemical left on the surface of the timber.

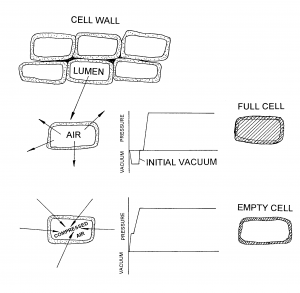

The first essential step in the empty-cell method is the application of the initial

pressure. As soon as the tank is sealed, an initial pressure of up to 35-40 psi is

applied to compress air into the cell lumens. The purpose of compressed air is to

pull out preservative injected into the lumen at the end of the treatment process

as illustrated in Figure 4. The tank is filled with the chemical while the initial

pressure is held on the charge. Later, the pressure is increased to 140-150 psi and

held for several hours. Next the pressure on the cylinder is relieved before applying

a final vacuum to clean the excessive chemical on the surface of the load similar

to the process of the full-cell method.

Figure 4. Schematics illustration between full-cell and empty-cell treatment methods.

In contrast to the empty-cell treatment, in the full-cell technique first a vacuum is applied into the tank to pull out air and free water located in the lumens rather than keeping the chamber under pressure. Therefore, both lumens and cell walls are left full of preservative at end of the treatment process. Figures 5 and 6 show typical treatment schedules for empty- and full-cell methods, respectively.

Preservative Chemicals

Preservative chemicals used for the pressure treatment process can be classified into three groups: tar oil based, oil-borne, and water-borne preservatives. Creosote is the most commonly used tar oil preservative chemical. It is often called coal tar creosote because of its close relationship to toluene, benzene, and tar. These materials are condensed from the distillation of coal as it is converted to carbon. Creosote penetrates deep into and remains in the wood for a long time. Exposure to creosote may be harmful to humans and special precautions should be taken for handling creosote-treated wood products. It can be successfully used for farm, fence, and other outdoor building materials. Railroad ties are commonly treated with creosote as illustrated in Figure 7. However creosote should not be used for the interior of farm buildings.

Figure 7. Creosote treated railroad ties.

An oil borne preservative, pentachlorophenol (PF) is also widely used to treat wood products. PF-treated wood can be used for commercial interior applications except for laminated beams or as construction component where a direct ground contact exists. In a typical application, the surface of the treated laminated beam should be coated with a sealer.

Arsenic and copper-based preservatives, such as ammonium copper zink arsenate (ACZA), ammoniacal copper arsenate (ACA), chromated copper arsenate (CCA), and copper naphthenate are water-borne preservatives which have been used extensively by the wood processing industry for many years. Copper naphthenate is normally supplied as a 6% or an 8% copper concentrate which is diluted with a petroleum hydrocarbon to provide a 0.5-2.0% copper concentrate solution. Preservative companies producing CCA, which is one of the most commonly used preservatives on the market, have requested the cancellation of that product for certain uses due to possible health concerns. The Environmental Protection Agency (EPA) has accepted this request and as of December 31, 2003 no wood will be treated with CCA for residential uses such as decking, playground, and constructional purposes. However, CCA will still be used for non-residential application. Similar to PF and creosote, arsenic-based chemicals are also poisonous. Special precautions stated on the consumer’s safety information label should be followed closely.

No matter what kind of chemical is used as a preservative, the quality of the treatment process greatly depends on the amount of the chemical injected into the wood. Therefore, the retention level is an important quality control measure of treated wood products. Retention level refers to the amount of preservative that remains in the wood after the treatment process is completed. It is expressed as weight of the liquid chemical per unit volume, usually lb/ft3 or kg/m3. Based on the exposure level, treated wood products should have a certain retention level as stated by the American Wood Preservers’s Association (AWPA). For example, if CCA treated wood is going to be used for ground contact or high moisture conditions it should have a retention value of 0.25 lbs/ft3 or 4.0 kg/m3 (1lbs/ft3 = 16 kg/m3 retention value). Lumber treated with a retention value of 0.60 kg/m3 is used for wood foundations, structural timber, etc. Retention value and other specific information of treated wood are stamped on the lumber.

Detailed information about pressure treatment of wood products can also be found in the following literature:

- The American Wood Preservers Institute. 1995. Answers to often asked Questions about Treated Wood. 1945 Old Gallow Road, Suite 150 Vienna, Virginia 22182-3931.

- Wilkinson. J,G. 1980. Industrial Timber Preservation. Associated Business Press. London.

- Cassens, D., Johnson, B., Feist.W., and DeGroot, R. 1995. Selection and Use of Preservative-Treated Wood. Forest Products Society. Publication No.7299. Madison, Wisconsin.

- Hamel, M. 1990. First International Conference on Wood Protection with Diffusible Preservatives. Forest Products Society. Proceedings 47355. Forest Products Society. Madison, Wisconsin.

- Trouser 1986. Wood Preserving Chemical and Procedure. The Ohio State University. Cooperative Extension Service.

Salim Hiziroglu

Assistant Professor, Forestry